USER MANUAL

May 4, 2023 · All Dakota Lithium and most lithium-ion batteries require a higher voltage than lead acid batteries to fully charge and perform best when charged with a lithium specific battery

Get Started

What Do S and P Mean on a Lithium Battery Pack?

Jun 18, 2024 · Let''s learn what S and P mean in lithium battery packs. Understand lithium cells series, parallel, and series-parallel connections.

Get Started

Paper Title (use style: paper title)

Jun 11, 2024 · Depending on the switch-matrix structure and the converter topology, energy can be transferred either from the battery string to the cell (S2C) or from the cell to the string (C2S)

Get Started

10s-16s Battery Pack Reference Design With Accurate

May 11, 2022 · Description This reference design is a low standby and ship-mode current consumption and high cell voltage accuracy 10s–16s Lithium-ion (Li-ion), LiFePO4 battery

Get Started

A novel active lithium-ion cell balancing method based on

May 6, 2025 · In series and parallel strings connected Lithium-ion (Li-ion) battery modules or packs, it is essential to equalise each Li-ion cell to enhance the power delivery performance

Get Started

Optimal Lithium Battery Charging: A Definitive

Mar 12, 2024 · Unlock the secrets of charging lithium battery packs correctly for optimal performance and longevity. Expert tips and techniques revealed in our

Get Started

How to Charge Lithium Batteries? Lithium

Jul 7, 2021 · In order to charge lithium batteries safely and effectively, it''s essential to have more comprehensive lithium battery charger design

Get Started

Lithium batteries for UPS applications

Feb 25, 2025 · As a means of protection, most lithium battery systems of almost any string voltage require a battery management system (BMS) to maintain the cell operating conditions

Get Started

FORMAT INSTRUCTIONS FOR SOMChE 2004 PAPERS

Sep 5, 2023 · The lithium-ion battery is important in the EV industry because it has superior properties to other batteries, such as high energy density, low self-discharge, and a long life

Get Started

Paper Title (use style: paper title)

Jun 11, 2024 · B. Experimental Setup To verify the performance of the proposed method as well as the theoretical analysis result, the hardware experiment is implemented with the lithium

Get Started

Practical Implications of Series and Parallel

Overview As lithium batteries become increasingly popular, it is essential to understand the practical implications of different styles of installation. The

Get Started

String Midpoint Monitoring for Li-Ion Batteries

Mar 14, 2024 · • The xEMU project selected a modular 28V battery design to improve operational reliability and minimize sparing requirements for long duration missions. –Uses multiple

Get Started

Lithium Series, Parallel and Series and Parallel

Mar 23, 2021 · Introduction Lithium battery banks using batteries with built-in Battery Management Systems (BMS) are created by connecting two or more batteries together to support a single

Get Started

A multi-winding transformer-based active cell equalizer with

Oct 15, 2023 · Balancing results of lithium-ion battery string Then, to validate the balancing effect for eight series-connected lithium-ion batteries, the turns ratio of the transformer was adjusted.

Get Started

Multi-Parameter Analysis of Li-ion Battery Degradation:

Mar 18, 2025 · The reliability and safety of Lithium-ion batteries (LiBs) are of great concern in the energy storage industry. Nevertheless, the real-time monitoring of their degradation remains

Get Started

The importance of degradation mode analysis in

Mar 21, 2025 · Accurately predicting battery lifetime is desirable. Here, the author shows that physics-based models for predicting lifetime of lithium-ion batteries must include how

Get Started

Improved voltage transfer method for lithium

Mar 22, 2021 · In order to cut the costs and overcome the leakage current of batteries caused in traditional method, this study introduces an improved

Get Started

A Modularized Two-Stage Active Cell Balancing Topology

Oct 17, 2024 · This paper introduces a modularized two-stage active cell balancing topology utilizing an improved buck-boost converter for a series-connected lithium-ion battery string.

Get Started

A Novel Modular Active Balancing Approach for a

May 31, 2025 · 1 Introduction Li-ion batteries, due to their complex electrochemical characteristics, necessitate a battery management system (BMS) to ensure safe operation and prolong their

Get Started

A Novel Modular Active Balancing Approach for a Lithium Battery String

Jun 1, 2025 · In this research, we present a novel approach for actively balancing a Lithium battery string, modularized into numerous cells in a series configuration, called the multi

Get Started

Advancement of lithium-ion battery cells voltage

Dec 1, 2020 · Recently, the use of electric batteries has reached great heights due to the invention of electric vehicles (EVs). Many lithium-ion battery cells are

Get Started

A Fast Charging Balancing Circuit for LiFePO4

Sep 5, 2019 · In this paper, a fast charging balancing circuit for LiFePO4 battery is proposed to address the voltage imbalanced problem of a lithium battery

Get Started

A multi-winding transformer-based active cell equalizer with

Oct 15, 2023 · A multi-winding transformer-based active cell equalizer with self-driven switches for series-connected lithium-ion batteries and super-capacitors

Get Started

An Improved Bi‐Switch Flyback Converter with

Apr 27, 2024 · A lithium-ion battery manufacturer can limit the range of current, voltage, and temperature to ensure safe operation. Most commonly, the

Get Started

(PDF) An Improved Bi-Switch Flyback Converter

Apr 27, 2024 · An Improved Bi-Switch Flyback Converter with Loss Analysis for Active Cell Balancing of the Lithium-Ion Battery String

Get Started

How many strings are 48V20AH lithium battery

Mar 3, 2021 · The whole set of batteries is 14 strings multiplied by 10 cells = 140 cells. Summary: Series and parallel have their own advantages for lithium iron

Get Started

Strings, Parallel Cells, and Parallel Strings

Feb 15, 2016 · Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However,

Get Started

State of Charge Imbalance Classification of Lithium-ion

Oct 2, 2022 · New York, NY, USA agl2142@columbia Abstract—Lithium-ion battery strings are important modules in battery packs. Due to cel. variation, strings may have im-balanced

Get Started

A Modularized Two-Stage Active Cell Balancing Topology

Oct 17, 2024 · This paper introduces a modularized two-stage active cell balancing topology utilizing an improved buck-boost converter for a series-connected lithium-ion batte

Get Started

A Low Cost and Fast Cell-to-Cell Balancing

Jan 3, 2020 · In order to prove the validity of the proposed method, a prototype circuit is built with twelve lithium-ion batteries in a string. The experimental

Get Started

Active cell voltage balancing of Electric vehicle batteries by

Jun 1, 2021 · In this paper, a closed-loop symmetric switched capacitor structure has been proposed for active cell voltage balancing of four series-connected lithium-ion cells of the

Get Started

An Improved Bi‐Switch Flyback Converter with

Apr 27, 2024 · This paper focuses on the active cell balancing of lithium-ion battery packs. An improved single-input, multioutput, bi-switch flyback

Get Started

Future smart battery and management: Advanced sensing from external

Mar 31, 2021 · Lithium-ion batteries (LIBs) has seen widespread applications in a variety of fields like the renewable penetration, electrified transportation, and portable electronics. A reliable

Get Started

6 FAQs about [Lithium battery string mode]

Can a lithium ion battery pack have multiple strings?

Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is the lowest cost and simplest. However, sometimes it may be necessary to use multiple strings of cells. Here are a few reasons that parallel strings may be necessary:

What is cell-to-cell balancing circuit for lithium-ion battery strings?

Based on the previous study, in this research a new cell-to-cell balancing circuit for lithium-ion battery strings is proposed to overcome the drawbacks of the conventional cell balancing methods. In the proposed topology, the charge is transferred from a high-voltage cell to a low-voltage cell directly by using a push-pull converter.

What is a battery string?

A battery string with a large number of cells connected in series and in parallel is necessary for many applications that require high power and high voltage, such as electric vehicles (EVs), hybrid electric vehicles (HEVs), and energy storage systems (ESSs) [ 1 ].

Why is it important to equalise lithium ion batteries?

In series and parallel strings connected Lithium-ion (Li-ion) battery modules or packs, it is essential to equalise each Li-ion cell to enhance the power delivery performance and usable capacity, otherwise, it is restricted by the worst cell in the string.

Are there any conflicts of interest in balancing lithium-ion battery packs?

The authors declare that they have no conflicts of interest. This paper focuses on the active cell balancing of lithium-ion battery packs. An improved single-input, multioutput, bi-switch flyback converter was proposed to achieve effective balancing.

What happens if a battery cell is connected in series?

As battery cells in a string are connected in series, the performance of the string is limited to the performance of the weakest cell and, hence, the capacity of the battery string will be reduced. During normal operation, the weakest cell undergoes overdischarge and undercharge and eventually reaches failure.

Related Articles

-

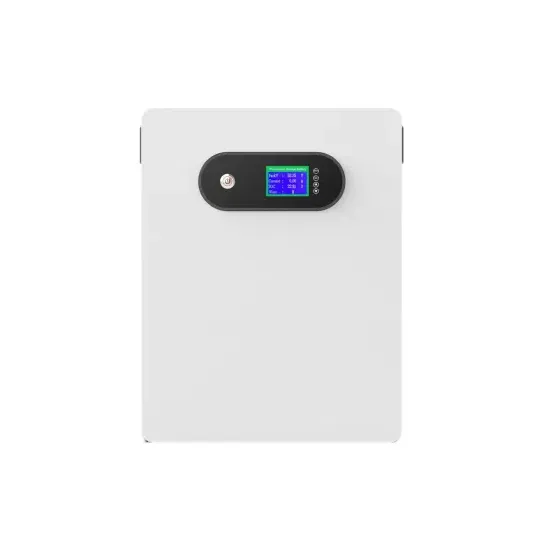

Kathmandu Energy Storage System Lithium Battery

Kathmandu Energy Storage System Lithium Battery

-

Polish container photovoltaic energy storage lithium battery brand

Polish container photovoltaic energy storage lithium battery brand

-

What are the lithium battery energy storage cabinet manufacturers in Guinea

What are the lithium battery energy storage cabinet manufacturers in Guinea

-

Communication base station lithium battery installation

Communication base station lithium battery installation

-

Huawei Energy Storage Lithium Battery System

Huawei Energy Storage Lithium Battery System

-

21v lithium battery pack can

21v lithium battery pack can

-

Beijing lithium battery bms development

Beijing lithium battery bms development

-

Rabat good lithium battery pack factory price

Rabat good lithium battery pack factory price

-

What is the largest size of cylindrical lithium battery in Australia

What is the largest size of cylindrical lithium battery in Australia

-

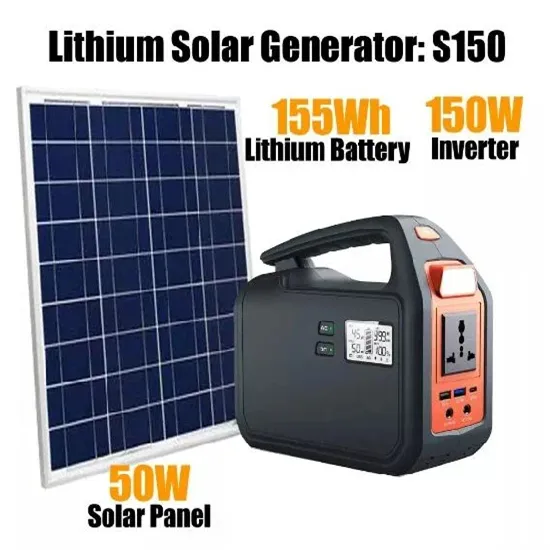

Greek lithium battery customized outdoor power supply

Greek lithium battery customized outdoor power supply

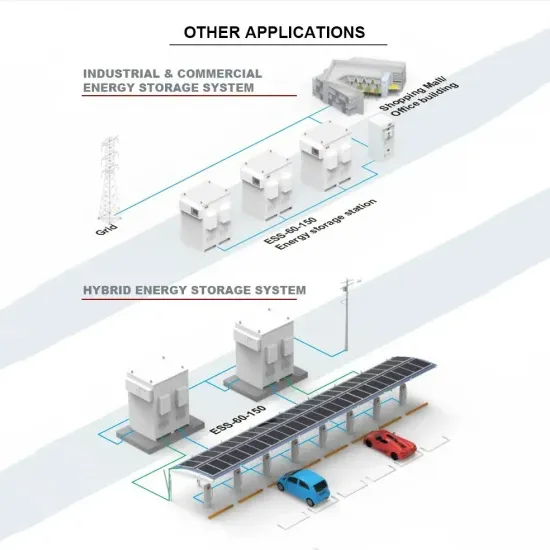

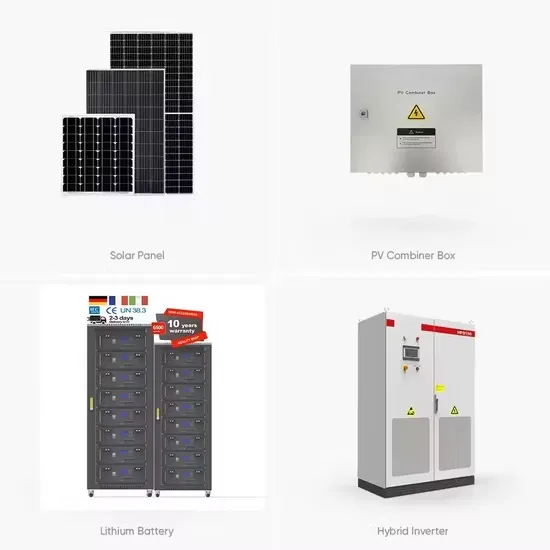

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.