Why DC Ground Faults Are Dangerous | Fluke

Jul 30, 2025 · By Will White, Fluke Senior Application Specialist, DER Ground faults are one of the most common issues in solar photovoltaic (PV) systems,

Get Started

DC Breaker Solar – An Important Part Of Photovoltaic Systems

Feb 17, 2025 · DC breaker solar are essential for protecting photovoltaic systems from overloads, short circuits, and equipment damage. They ensure safety and reliability in solar energy setups.

Get Started

Electrical testing standards guide for the PV Industry

Feb 24, 2025 · Electrical Testing Standards Guide Introduction A ground fault in a photovoltaic (PV) array is an accidental electrical short circuit between ground and one or more conductors

Get Started

ON THE GROUNDING AND BONDING OF SOLAR

Jul 30, 2025 · When a direct current (DC) conductor in a PV array makes unintended contact with grounded metal, it creates a DC ground fault that can

Get Started

ON THE GROUNDING AND BONDING OF SOLAR

Jan 4, 2021 · Solar PV systems are still permitted to be grounded, per 690.41 (A) (1) and (5), and, for those PV systems that are, the dc grounded conductor is

Get Started

How to Quickly and Effectively Determine

Feb 14, 2022 · Disconnect the DC switch of each PV string connected to the inverter, and use a multi-meter to measure the voltage of the PV+ to ground

Get Started

Grounding and Methods of Earthing in PV Solar

2 days ago · However, there are multiple methods for grounding DC systems in PV arrays. The recommended approach is to use a separate DC grounding

Get Started

Common-Ground Photovoltaic Inverters for

Nov 28, 2021 · In photovoltaic systems, parasitic capacitance is often formed between PV panels and the ground. Because of the switching nature of PV

Get Started

How to Select the Proper DC SPD (Surge

3 days ago · A solar surge SPD is designed to protect your solar panels and associated equipment from power surges and transient voltage spikes. It

Get Started

Solis Seminar 【Episode 39】: How to Quickly

Feb 9, 2022 · PV string grounding: There are generally three reasons for PV power station string grounding faults: 1) The insulation layer of the DC cable of

Get Started

PowerPoint Presentation

Feb 23, 2025 · However, some PV Ground Fault Protectors use a ~.5A-1A circuit breaker or fuse in series with the system bonding jumper to detect ground faults. In this case, if a ground fault

Get Started

Photovoltaic System Grounding

4 days ago · He installed his first photovoltaic (PV) power system in 1984 and has been involved in the design, installation, inspection, and testing of PV systems for 28 years. He is a member

Get Started

Leakage Current Control in Solar Inverter

Oct 6, 2019 · The photovoltaic cell is disconnected from the grid during current freewheeling to prevent the panel pole-to-ground voltage from fluctuating with

Get Started

Field Guide for Testing Existing Photovoltaic Systems for

Mar 21, 2016 · This report provides field procedures for testing PV arrays for ground faults, and for implementing high-resolution ground fault and arc fault detectors in existing and new PV

Get Started

GROUND-FAULT PHOTOVOLTAIC ANALYSIS AND

Aug 1, 2024 · two types of groundings in PV arrays. The first one is system grounding: the PV system with system voltage over 50 v. lts should be solidly system-grounded. To achieve that,

Get Started

ASSR-601J Insulation Resistance Measurement for

2 days ago · Introduction Transformerless photovoltaic (PV) inverter systems are getting popular these days due to lower system cost, higher efficiency, easier installation and maintenance.

Get Started

Technical Information

Feb 3, 2025 · Since the leakage current is directly dependent on the capacitance of the PV module to ground, for each AC voltage to ground a capacitance limit can be specified, above

Get Started

Best Practices in PV System Ground Fault Testing

Sep 18, 2023 · Ground faults are common faults in PV systems. They manifest as an electrical connection between ground and one or more current-carrying

Get Started

Solis Seminar 【Episode 39】: How to Quickly

Feb 11, 2022 · 3) The insulation layer of the DC cable connecting the string to the inverter is damaged and connected to the ground. Troubleshooting:

Get Started

How to Detect Ground Faults in Your PV System

Jun 25, 2025 · Share this article: Share via Email How to Detect Ground Faults in Your PV System Introduction: Ground faults in PV systems are one of the

Get Started

Size wire for solar grounding

May 10, 2024 · I currently have 2 positive and 2 negative 10 AWG wires running out to my solar 2 arrays in my back yard. I''m run a ground wire to the panels and connect to my house''s

Get Started

To Ground or Not to

Nov 21, 2013 · Electrical systems in the U.S. (including PV systems) are generally solidly grounded to limit the voltage with reference to ground during normal operation, and to prevent

Get Started

Solis Seminar 【Episode 39】: How to Quickly and Effectively

Jan 27, 2022 · Troubleshooting: Disconnect the DC switch of each PV string connected to the inverter, and use a multi-meter to measure the voltage of the PV+ to ground and PV- to

Get Started

Earthing Solar Panels: Grounding of photovoltaic modules

Feb 28, 2025 · Essentially, earthing keeps the electric potential of metallic parts at ground level, preventing voltage differences between them or with respect to the ground. What is meant by

Get Started

Guidelines for Designing Grounding Systems for

Nov 28, 2022 · Grounding and bonding is a subject area that can be confusing to many. In this blog post, we summarize key points according to the NEC. The

Get Started

Proper Grounding of Photovoltaic Panels

Proper grounding of a photovoltaic installation involves several key steps. Site Assessment. The first step is to evaluate the building structure and the

Get Started

Short Circuit and Fault Current Analysis in Solar PV Systems

Feb 26, 2025 · Solar photovoltaic (PV) systems are becoming a dominant source of renewable energy. However, like all electrical power systems, they are susceptible to faults, including

Get Started

A guide to DC Drop | Greenwood

Aug 16, 2025 · Volt drop is a decrease of electrical potential when current flows in an electrical circuit and is affected by the properties of the cable that has been

Get Started

Checking the PV System for Ground Faults

Apr 15, 2019 · Check the PV system for ground faults by measuring the voltage. If the voltage measurement was not successful, check the PV system via insulation resistance

Get Started

How to check the grounding of photovoltaic panels

How to check the grounding of photovoltaic panels From what I''''ve read the general consensus for 12V DC off-grid systems seems to be that you should run a ground wire. from components

Get Started

6 FAQs about [Photovoltaic panel DC voltage to ground]

How do I ground a DC system in a PV array?

However, there are multiple methods for grounding DC systems in PV arrays. The recommended approach is to use a separate DC grounding electrode for PV arrays and frames, as this enhances protection against lightning and transient voltage. For lightning protection associated with grounding systems, refer to NFPA 780 and NEC 250.106.

Does a PV system need a DC grounding system?

In this scenario, the equipment grounding conductor (EGC) of the PV circuit can be connected to the grounding terminal of the inverter, which is eventually connected to the AC grounding system and electrode within the premises. Hence, this practice eliminates the need for a separate DC grounding system for the PV system.

What is the difference between AC and DC grounding in PV systems?

Both grounding electrode conductors (GEC) are connected to the individual grounding rod used for both systems. Meanwhile, both ground electrodes (AC ground rod and DC ground rod) are bonded through a bonding jumper as required by NEC. The following fig shows an alternative way of grounding AC and DC in PV systems.

What is a DC ground fault in a PV system?

DC ground faults are the most common type of fault in PV systems and half go undetected. A DC ground fault is the undesirable condition of current flowing through the equipment grounding conductor in the circuits carrying DC power (before the inverter).

How to ground a PV system?

ing has m modules in series.GroundingIn the requirement of the NEC Article 690.41, there ar two types of groundings in PV arrays. The first one is system grounding: the PV system with system voltage over 50 v lts should be solidly system-grounded. To achieve that, the negative conductor usually is grounded via the GFPD in t

Can a solar PV system be grounded?

Solar PV systems are still permitted to be grounded, per 690.41 (A) (1) and (5), and, for those PV systems that are, the dc grounded conductor is directly coupled (or coupled through electronic circuitry) to the ac grounded conductor, which is then brought to ground potential by being terminated to the neutral bus bar at the main service panel.

Related Articles

-

Photovoltaic panel current DC

Photovoltaic panel current DC

-

The voltage and current of the photovoltaic panel drop instantly

The voltage and current of the photovoltaic panel drop instantly

-

Is the voltage of the solar panel photovoltaic panel 6 9v normal

Is the voltage of the solar panel photovoltaic panel 6 9v normal

-

The voltage of photovoltaic panel and battery is consistent

The voltage of photovoltaic panel and battery is consistent

-

Photovoltaic panel and battery voltage

Photovoltaic panel and battery voltage

-

Photovoltaic panel output voltage fluctuation

Photovoltaic panel output voltage fluctuation

-

Photovoltaic panel input voltage is low

Photovoltaic panel input voltage is low

-

Garagasmi photovoltaic panel output voltage

Garagasmi photovoltaic panel output voltage

-

What is the output voltage of a 460 watt photovoltaic panel

What is the output voltage of a 460 watt photovoltaic panel

-

Voltage of the cells on the photovoltaic panel

Voltage of the cells on the photovoltaic panel

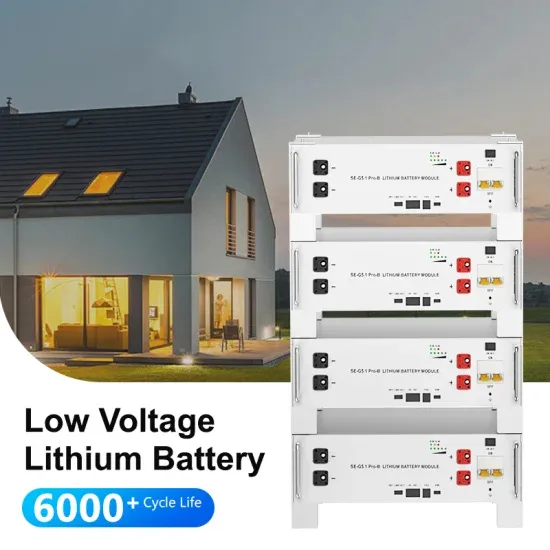

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.