How does a Three Phase Inverter Work?

Dec 15, 2023 · Three-phase inverters play a crucial role in converting direct current (DC) power into alternating current (AC) in various applications, from

Get Started

How an Inverter Drive Works and Controls the Speed of an AC Induction Motor

An Inverter Drive (VFD) works by taking AC mains (single or three phase) and first rectifying it into DC, the DC is usually smoothed with Capacitors and often a DC choke before it is connected

Get Started

Three Phase Inverter : Circuit, Working, Types

May 31, 2023 · A 3-phase inverter mainly includes three 1-phase inverter switches wherever every switch in this circuit is connected from three load terminals

Get Started

What is Three Phase Inverter and How Does It Work

Aug 1, 2025 · What is three phase inverter? That is a device that converts direct current (DC) power into alternating current (AC) in three separate phases. For better understanding this

Get Started

Three Phase Bridge Inverter Explained

Sep 6, 2020 · A three phase bridge inverter is a device which converts DC power input into three phase AC output. Like single phase inverter, it draws DC

Get Started

Modeling a Three-Phase Inverter | How to Design Motor

2 days ago · A three-phase inverter is basically a circuit that converts DC to AC current using three pairs of inverter switches, each corresponding to a phase. Based on how you want to model the three-phase inverter, you can choose from different options that are available under the

Get Started

Simple 3 Phase Inverter Circuit

Jun 30, 2025 · In this post I have explained how to make a 3 phase inverter circuit which can be used in conjunction with any ordinary single phase square wave

Get Started

Three-Phase Inverter-Fed Induction Motor Drives

Dec 27, 2024 · Four case studies are presented: one for the three-phase space vector pulse width modulated (SVPWM) inverter-fed IM drive, the second for that of vector controlled IM drive fed

Get Started

Three Phase Inverter Circuit Diagram

May 31, 2023 · A 3-phase inverter mainly includes three 1-phase inverter switches wherever every switch in this circuit is connected from three load terminals

Get Started

Three-Phase Inverters

Modern electronic systems cannot function without three-phase inverters, which transform DC power into three-phase AC power with adjustable amplitude, frequency, and phase difference.

Get Started

Three-phase inverter for the ac motor drive.

Download scientific diagram | Three-phase inverter for the ac motor drive. from publication: Space-vector PWM technique for two-phase inverter-fed two

Get Started

Single vs. Three Phase Inverter | inverter

Dec 15, 2023 · Three-phase inverter: Specifically designed for three-phase motors, which are prevalent in industrial and commercial settings. Three

Get Started

3 Phase Motor Inverter Wiring Diagram

Jan 15, 2018 · A three-phase motor inverter is a device that converts direct current (DC) electricity into alternating current (AC) electricity. This conversion

Get Started

3 Phase Inverter Circuit Diagram Using Mosfet

Sep 8, 2017 · A three phase inverter consists of three half-bridge inverter circuits connected in a series. Each half-bridge inverter is composed of two MOSFETs

Get Started

How to Wire a VFD with Motor, PLC and External

4 days ago · Power Wiring: Connect the 415V AC three-phase power supply from the 3-P MCCB to the VFD''s L1, L2, and L3 terminals. Then, wire the three

Get Started

Three-phase and single-phase motor drive system with single three-phase

Nov 15, 2021 · This paper presents a dual-motor drive system with a three-phase two-level inverter for independent speed control of a three-phase motor and a single-phase motor. The

Get Started

Syncing 2 off grid inverters to achieve 2 phases of 3 phase

Oct 8, 2020 · There are various single phase inverters on the market, both off grid and on grid which will allow you to buy three of them and connect together to sync up as a 3 phase supply.

Get Started

Basic scheme of 3-phase inverter connected to an AC motor

Download scientific diagram | Basic scheme of 3-phase inverter connected to an AC motor from publication: Fuzzy based direct torque and flux control of induction motor drives | This paper

Get Started

How to Reverse and Forward a 3-Phase Motor

3 days ago · How to Change the Direction of Motor Rotation Using a VFD? Variable Frequency Drives (VFDs) have revolutionized industrial automation

Get Started

How to Run a Three-Phase Motor on Single

3 days ago · Running a 3-Φ Induction Motor on a 1-Phase Supply – 3 Methods According to the type of AC power supply, induction motors are classified into

Get Started

AC Motor Inverters: How They Work, Principles, And

May 19, 2025 · An inverter drive, or Variable Frequency Drive (VFD), converts AC mains into DC using rectification. Capacitors and sometimes a DC choke smooth the DC current. The

Get Started

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · This reference design is a three-phase inverter drive for controlling AC and Servo motors. It comprises of two boards: a power stage module and a control module.

Get Started

48-V Three-Phase Inverter With Shunt-Based In-Line

Apr 7, 2017 · The three-phase motor is connected to the three-phase motor terminal. An optional electromagnetic interference (EMI) filter can be added for slew rate reduction, as explained in

Get Started

AC Motor Inverters: How They Work, Principles, And

May 19, 2025 · AC motor inverters are devices that convert direct current (DC) into alternating current (AC) to control the speed and torque of electric motors. They are essential for

Get Started

DESIGN AND IMPLEMENTATION OF THREE PHASE

Apr 21, 2019 · Abstract This paper describes the design and implementation of three-phase inverter. Generally inverters are used in high power applications as industrial based induction

Get Started

3 phases inverter output current

Apr 12, 2023 · A three-phase inverter''s output current varies with the load. If it is wired to an alternating current (AC) motor, for instance, the current will change based on the load on the

Get Started

Three Phase Inverter Circuit Diagram

Mar 2, 2021 · Unlike single-phase inverters that produce one AC waveform, a 3 phase inverter circuit diagram shows six switching elements arranged to

Get Started

How to connect a single-phase motor to the inverter

Mar 28, 2025 · The single-phase electric motor has an electrical phase shift necessary to make the motor "work" through a capacitor. The compromise to be accepted, using the capacitor, is

Get Started

AC Motor Inverter Design: Strategies For Efficient Speed

Apr 14, 2025 · Overall, a well-designed AC motor inverter ensures reliable and efficient speed control for three-phase drives. With these foundational strategies in place, the next section will

Get Started

Three Phase Inverter : Circuit, Working and Its

A three-phase inverter is used to change the DC voltage to three-phase AC supply. Generally, these are used in high power and variable frequency drive

Get Started

6 FAQs about [Inverter connected to AC three-phase motor]

What are the applications of 3 phase inverter?

The applications of three phase inverter include the following. A three-phase inverter is mainly used for converting a DC input into an AC output. This inverter generates 3-phase AC power using a DC power source. It is used in high-power-based applications like HVDC power transmission.

What is a three-phase inverter?

Modern electronic systems cannot function without three-phase inverters, which transform DC power into three-phase AC power with adjustable amplitude, frequency, and phase difference. They are essential in several applications, including as power distribution networks, renewable energy systems, and industrial motor drives.

What is AC motor inverter?

AC motor inverters are devices that convert direct current (DC) into alternating current (AC) to control the speed and torque of electric motors. They are essential for improving energy efficiency in various applications, such as fans, pumps, and conveyor systems. 1. Functionality 2. Types 3. Applications 4. Benefits 5. Considerations

What is the difference between a 3 phase and a single phase inverter?

In a 3 phase, the power can be transmitted across the network with the help of three different currents which are out of phase with each other, whereas in single-phase inverter, the power can transmit through a single phase. For instance, if you have a three-phase connection in your home, then the inverter can be connected to one of the phases.

How does an inverter control AC motor speed?

The inverter circuit functions to control AC motor speed by converting direct current (DC) into alternating current (AC). First, the inverter receives DC from a power source, often a battery or a rectified supply. Next, it uses power electronic devices, such as transistors, to switch the DC voltage on and off rapidly.

What is a 3 phase square wave inverter?

A three-phase square wave inverter is used in a UPS circuit and a low-cost solid-state frequency charger circuit. Thus, this is all about an overview of a three-phase inverter, working principle, design or circuit diagram, conduction modes, and its applications. A 3 phase inverter is used to convert a DC i/p into an AC output.

Related Articles

-

Inverter output connected to three-phase motor

Inverter output connected to three-phase motor

-

Three-phase inverter with single-phase motor

Three-phase inverter with single-phase motor

-

Inverter connected to three-phase power

Inverter connected to three-phase power

-

AC power connected to DC inverter

AC power connected to DC inverter

-

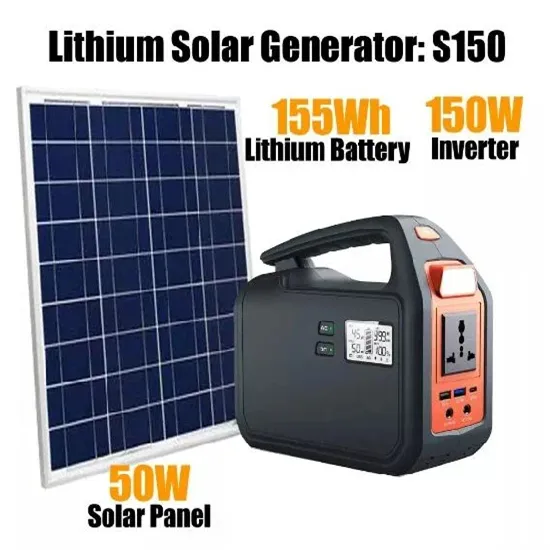

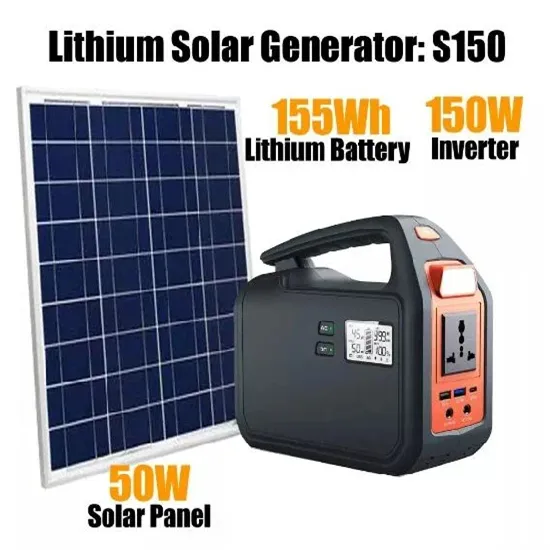

Inverter connected to high-power electrical appliances

Inverter connected to high-power electrical appliances

-

Hybrid three-phase and battery inverter

Hybrid three-phase and battery inverter

-

Voltage inverter DC 110v to AC

Voltage inverter DC 110v to AC

-

Inverter can supply AC power

Inverter can supply AC power

-

Three-phase inverter brand manufacturers in Sydney Australia

Three-phase inverter brand manufacturers in Sydney Australia

-

Photovoltaic inverter connected to high voltage system

Photovoltaic inverter connected to high voltage system

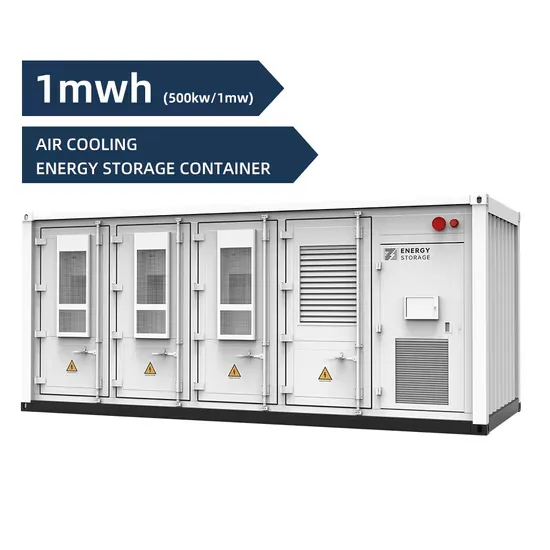

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.