Battery Cabinet

Feb 28, 2025 · Purpose This manual contains information on Atlantic Battery Systems battery cabinets. The information in this manual is intended for Qualified Installers, Equipment

Get Started

Understanding Backup Battery Requirements for

Mar 7, 2025 · Telecom base stations require reliable backup power to ensure uninterrupted communication services. Selecting the right backup battery is

Get Started

The Complete Guide to Understanding Battery Case and

Apr 11, 2025 · Flooded lead acid battery cases and covers are engineered from impact-resistant polypropylene to withstand corrosion, contain electrolytes, and prevent leaks. Their design

Get Started

What are the OSHA Requirements for Battery

Oct 16, 2023 · What are the OSHA Requirements for Battery Storage (2023) Last Updated: 16 October 2023 OSHA requirements for battery storage are

Get Started

Lead-acid Battery for Telecom Base Station Market

Sub-Saharan Africa''s 470,000 base stations rely on lead-acid batteries for 80% of backup systems due to extreme affordability constraints. MTN Group and Airtel Africa deploy hybrid

Get Started

Lead-Acid Batteries and Steps of Battery

Mar 29, 2019 · Introduction to Lead-Acid Batteries Therefore, this article is intended to give a brief idea of lead acid battery manufacturing process. A

Get Started

LONG-DURATION DUTY CYCLE REQUIREMENTS: IS THE

Jul 26, 2019 · INTRODUCTION Stationary lead-acid batteries remain the economical first choice for standby power batteries with discharge times between 15min and 8h; they have been well

Get Started

有道翻译_文本、文档、、在线即时翻译

有道翻译提供即时免费的中文、英语、日语、韩语、法语、德语、俄语、西班牙语、葡萄牙语、越南语、印尼语、意大利语、荷兰语、泰语全文翻译、翻译、文档翻译、PDF翻译、DOC

Get Started

Lead–acid battery fundamentals

Jan 1, 2017 · Consequently, despite the antiquity of the central concept, the lead–acid battery has continued to be the most widely-used rechargeable battery system in automobiles. With the

Get Started

Use of Batteries in the Telecommunications Industry

Mar 18, 2025 · Who or What is ATIS? The Alliance for Telecommunications Industry Solutions is an organization that develops standards and solutions for the ICT (Information and

Get Started

What are the functions of lead-acid energy storage power stations

Jun 19, 2024 · 1. ENERGY STORAGE The backbone of lead-acid energy storage power stations lies in their ability to efficiently store and release electrical energy. When electricity generation

Get Started

Battery Room Design Requirements –

Battery Room References Institute of Electrical and Electronic Engineers (IEEE) 484 Recommended Practice for Installation Design and Installation of Vented

Get Started

Key Considerations When Installing Lead-Acid

Sep 27, 2024 · When installing lead-acid batteries in telecom base stations, several critical factors must be considered to ensure efficient, safe, and long

Get Started

Lead Acid Battery

Lead–Acid Battery The lead–acid battery is the workhorse for industrial traction applications. It is the cheapest system, with a reasonable price-to-performance relation. Valve-regulated,

Get Started

What Powers Telecom Base Stations During Outages?

Feb 20, 2025 · Telecom batteries for base stations are backup power systems using valve-regulated lead-acid (VRLA) or lithium-ion batteries. They ensure uninterrupted connectivity

Get Started

Lead-Acid vs. Lithium-Ion Batteries for Telecom

Mar 7, 2025 · Two primary battery technologies dominate the telecom backup power industry: lead-acid and lithium-ion. Each has its advantages and trade

Get Started

Lead-Acid vs. Lithium-Ion Batteries for Telecom

Mar 7, 2025 · While lead-acid batteries remain a cost-effective option, lithium-ion batteries are gaining popularity due to their longer lifespan, reduced

Get Started

Lead-Acid Batteries: Key Advantages and Disadvantages

Feb 12, 2025 · Explore lead-acid batteries: key advantages and disadvantages, helping you make informed choices for your power needs.

Get Started

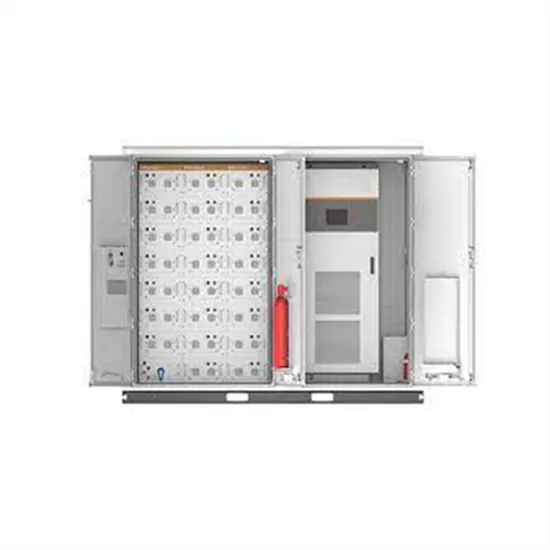

BATTERY CABINETS CATALOGUE

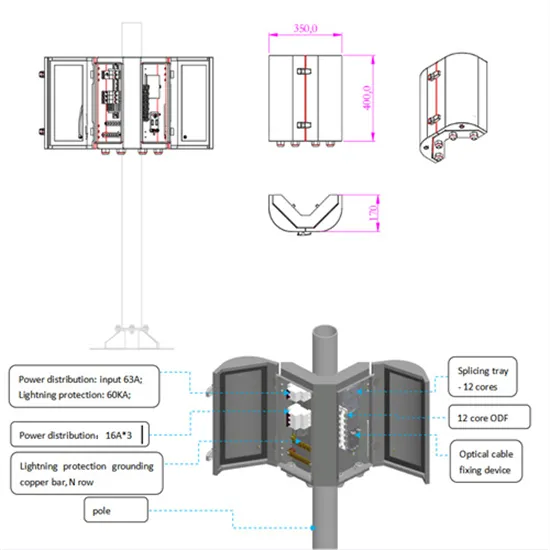

Jun 4, 2025 · The cabinets covered by the technical specification have been designed to contain the hermetic lead-acid electric accumulator batteries. The construction characteristics of the

Get Started

What Are the Requirements for Storage of Lead

Jul 19, 2024 · Sealed Lead-Acid (AGM, Gel) Batteries: These are generally maintenance-free but should still be stored in a cool, dry place and

Get Started

lead-aCid battery

May 25, 2020 · A. Physical principles A lead-acid battery system is an energy storage system based on electrochemical charge/discharge reactions that occur between a positive electrode

Get Started

Lead-Acid Battery Lifetime Estimation using Limited

Jan 21, 2024 · Abstract—Determining battery lifetime used in cellular base stations is crucial for mobile operators to maintain availability and quality of service as well as to optimize

Get Started

what must be stored in a dedicated battery storage cabinet

1. Batteries Of course, the most obvious item to be stored in a dedicated battery storage cabinet is batteries. This includes all types of batteries, from alkaline and lithium batteries to nickel-metal

Get Started

Maintaining Compliance in the VRLA Battery Room

Dec 20, 2022 · Introduction Battery room compliance can be interpreted differently depending on your battery type, amount of cells or multi-cell units in a common area, volume of electrolyte

Get Started

Battery Room Ventilation Code Requirements

Feb 19, 2018 · Battery room ventilation codes and standards protect workers by limiting the accumulation of hydrogen in the battery room. Hydrogen release is

Get Started

C & D Technologies | Stationary Battery Cabinets

C&D battery cabinets and enclosures Battery cabinet solutions for pure lead agm batteries From the industry leader in data center backup batteries, C&D now

Get Started

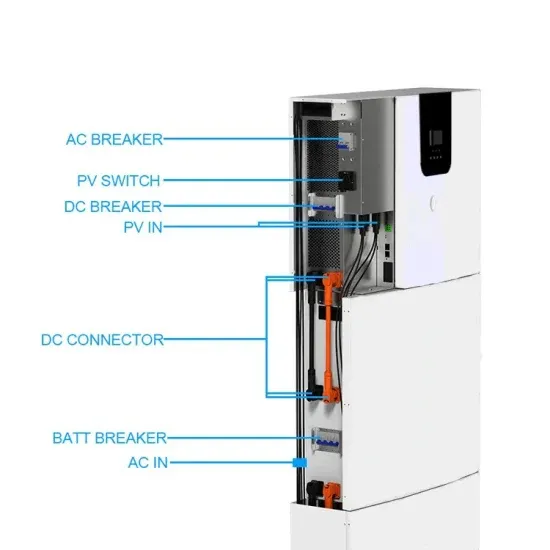

Battery Cabinet

Mar 21, 2023 · Before the BCB switch is turned on, the SmartLi can automatically detect the insulation impedance of the positive and negative battery terminals to PE, ensuring safe

Get Started

What are the base station energy storage

May 28, 2024 · Their primary role lies in storing electric energy for backup purposes, ensuring that base stations remain operational during grid outages

Get Started

The Science Behind the Spark: How Lead Acid

Apr 1, 2025 · The Science Behind the Spark: How Lead Acid Batteries Work Lead acid batteries are a marvel of chemistry and engineering, providing reliable

Get Started

6 FAQs about [Which base stations are covered by the lead-acid battery cabinet ]

Which accumulator batteries are included in the cabinets covered by the technical specification?

The cabinets covered by the technical specification have been designed to contain the hermetic lead-acid electric accumulator batteries.

Do data center and network room UPS systems use lead-acid batteries?

Although alternative energy storage technologies such as fuel cells, flywheels, lithium ion, and nickel cadmium batteries are being explored (see White Paper 65, Comparing Data Center Batteries, Flywheels, and Ultracapacitors for more details) data center and network room UPS systems almost exclu-sively utilize lead-acid batteries.

What is a lead-acid battery?

The lead-acid battery is the predominant choice for uninterruptible power supply (UPS) energy storage. Over 10 million UPSs are presently installed utilizing flooded, valve regulated lead acid (VRLA), and modular battery cartridge (MBC) systems. This paper discusses the advantages and disadvantages of these three lead-acid battery technologies.

Where can I find the instruction manual for the batteries?

Inside the door there is a document pocket containing the instruction manual for the batteries. The sections can be fixed together to form a single cabinet. Where required, the cabinet is completed by a special compartment or switch/disconnector cubicle containing the protection equipment.

Where should a flooded battery be installed?

Because they continuously vent gases, flooded batteries must be installed in controlled-access areas such as specially ventilated battery rooms with spill containment. Flooded battery systems are usually considered part of the building’s fixed power infrastruc-ture. Flooded batteries require periodic inspection of electrolyte and plates.

Do flooded or wet cell batteries need a separate room?

Vented (flooded or wet cell) batteries have a very long life but present significant complexity of installation and maintenance, the most significant being the need to build a separate battery room. These limitations have historically restricted the application of vented cells to very high power installations.

Related Articles

-

Ljubljana communication base station lead-acid battery cabinet in stock

Ljubljana communication base station lead-acid battery cabinet in stock

-

Lead-acid battery photovoltaic for communication base stations

Lead-acid battery photovoltaic for communication base stations

-

Which is better battery or cabinet for communication base station

Which is better battery or cabinet for communication base station

-

Battery energy storage system for communication base stations reduces energy consumption at night

Battery energy storage system for communication base stations reduces energy consumption at night

-

Battery types for communication base stations

Battery types for communication base stations

-

Which company should I choose for Cuba s outdoor communication battery cabinet

Which company should I choose for Cuba s outdoor communication battery cabinet

-

Battery cable model for communication base stations

Battery cable model for communication base stations

-

Square battery energy storage cabinet design base station

Square battery energy storage cabinet design base station

-

Which is the best integrated power cabinet for 5g base station in Tallinn

Which is the best integrated power cabinet for 5g base station in Tallinn

-

Which cities have hybrid energy 5g base stations with 2MWH

Which cities have hybrid energy 5g base stations with 2MWH

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.