What is Inverter? Components, Working

An inverter typically consists of several key components, each serving a specific function in the process of converting direct current (DC) into alternating current

Get Started

Solar inverter components + introduction and

Jul 27, 2025 · What is a Solar Inverter? A solar inverter is an electronic unit that converts DC energgenerated by solar panels into AC, which is the standard

Get Started

Guide to Frequency Inverters: Optimizing Motor

Nov 13, 2024 · I. Introduction to Frequency Inverters (VFDs) Frequency inverters, also known as variable frequency drives (VFDs), are essential components in

Get Started

Understanding High-Frequency Inverters

6 days ago · In the realm of power electronics, the advent of high-frequency inverters has revolutionized the landscape. These enigmatic devices possess the uncanny ability to

Get Started

Introduction to inverters: structure, operating

May 24, 2024 · Discover the basics of inverters - their structure, operating principles, and functions. Explore Junchipower''s expertise in this informative

Get Started

Understanding the Inverter PCB Diagram: A

Another important component in an inverter PCB diagram is the oscillator circuit. This section consists of a crystal oscillator or an RC circuit that generates a

Get Started

High-frequency Power Inverter

High-frequency power inverters, or HF power inverters, are widely used for converting DC power to AC power with compact designs and high efficiency levels. These inverters are particularly

Get Started

MIT Open Access Articles A High Frequency Inverter for

Oct 1, 2022 · This paper presents a high-frequency inverter system that can directly drive widely-varying load impedances with high efficiency and fast dynamic response. Based on the

Get Started

6.4. Inverters: principle of operation and

The low frequency inverters typically operate at ~60 Hz frequency. To produce a sine wave output, high-frequency inverters are used. These inverters use the

Get Started

Frequency Converter Structure: A Deep Dive for Efficiency

Jan 14, 2024 · Introduction: A frequency converter, often referred to as a frequency inverter, is a crucial element in many electrical systems. But what exactly lies behind it? Essentially, a

Get Started

What is a High-Frequency Power Inverter?

Apr 16, 2025 · By AC Output Frequency: Industrial frequency inverter (frequency: 50- 60Hz), medium frequency inverter (frequency: 400Hz-20kHz), and high

Get Started

A comprehensive review on inverter topologies and control strategies

Oct 1, 2018 · The traditional PWM based buck-boost inverter topologies have several disadvantages such as, (a) high-frequency harmonic components causing EMI, (b) large

Get Started

Importance of DC-Link Capacitors in High Power

Mar 11, 2025 · Introduction In high-power inverter designs, such as those used in electric vehicles, renewable energy systems, industrial motor drives, and high

Get Started

High-Frequency Variable Load Inverter Architecture

Jun 4, 2025 · The invented high-frequency inverter system enables HF power delivery directly into highly variable impedance loads with a relatively high efficiency. A pair of inverters are coupled

Get Started

High-Frequency Inverter: How They Work and

3 days ago · What is a high-frequency inverter? What components make it different from other inverters? What are the benefits of using a high-frequency

Get Started

Magnetic Core Materials in Inverters – Why Are They Important?

Jul 18, 2025 · Future developments in magnetic core materials will focus on: High-Frequency, Low-Loss Materials: The growing adoption of high-frequency inverters will drive demand for

Get Started

What is a High-Frequency Power Inverter?

1 day ago · Introduction A power inverter converts DC power into AC power for operating AC loads and equipment. High-frequency power inverters utilize

Get Started

Understanding High-Frequency Inverters

6 days ago · Benefits of High-Frequency Inverters: Uncover the advantages offered by high-frequency operation, such as reduced size, improved efficiency, and noise suppression.

Get Started

High Frequency Inverter Circuit

Nov 19, 2019 · The most important component of a high frequency inverter circuit is the transformer. This component is responsible for converting the DC current into AC power.

Get Started

High-frequency inverter technology: the next leap forward

Feb 28, 2025 · High-frequency inverter technology: the next leap for solar inverters I. Introduction In today''s critical period of global energy transformation, solar energy, as a clean and

Get Started

High-Frequency Inverter: How They Work and

3 days ago · Regarding small—to medium-sized inverters, the high-frequency inverter is the market-dominating choice due to its high efficiency, compact

Get Started

What Components In An Inverter Convert DC To

Jan 25, 2025 · Learn about the components in an inverter that convert DC to AC. Explore the role of power transistors, transformers, capacitors, and control

Get Started

Design and Development of High Frequency Inverter for

One of the most critical components of the WPT system is the HF inverter. There are many topologies of high frequency inverter. Among them H bridge are used in simulation and half

Get Started

Advantages of High-Frequency Inverters in

Enhanced Efficiency High-frequency inverters are known for their high efficiency, which is one of their most significant advantages. By operating at higher

Get Started

High Frequency Inverter Circuit Diagram

Jul 11, 2022 · The High Frequency Inverter Circuit Diagram also makes it easier to detect and troubleshoot problems with faulty power sources or signals,

Get Started

The difference between a high and low frequency inverter

Understanding the differences between a high and low frequency inverter helps you make informed decisions. High frequency inverters offer compactness and efficiency, making them

Get Started

Inverter Power Supply High

Jun 25, 2025 · Nickel-zinc ferrites are better suited for high frequency (above 1 MHz) applications based on better high-frequency characteristics and can withstand higher magnetic fields. In

Get Started

Major Components of Inverters

Nov 4, 2012 · Major components of an inverter An inverter design and components vary with requirements but following components are most

Get Started

Design and Development of High Frequency Inverter for

High frequency is necessary for many advantages. The use of high frequency in wireless power transfer allows for more efficient and precise transfer of energy, as well as potentially reducing

Get Started

Which is Better Low Frequency or High

3 days ago · Introduction Inverters convert DC power into AC power to operate AC equipment and devices. They utilize power electronic switching at different

Get Started

Inverters Inside: Components and How It Works

Nov 18, 2023 · A leading manufacturer of high-quality inverters and energy storage devices, our company has been providing reliable and innovative

Get Started

6 FAQs about [Important components of high-frequency inverter]

What are the components of a high frequency inverter circuit?

The most important component of a high frequency inverter circuit is the transformer. This component is responsible for converting the DC current into AC power. Depending on the application, different types of transformers can be used, such as pulse width modulated (PWM), full wave, half wave, and peak-to-peak.

What is a high frequency inverter?

High-frequency inverters generate the AC output waveform by switching power devices at frequencies much higher than the output frequency. Some key characteristics: They contrast with line-frequency inverters operating nearer to the AC output frequency. [Diagram] The inverter bridge contains power switches like IGBTs or MOSFETs.

What are the advantages and disadvantages of high frequency inverters?

Benefits of High-Frequency Inverters: Uncover the advantages offered by high-frequency operation, such as reduced size, improved efficiency, and noise suppression. Topologies of High-Frequency Inverters: Examine the different topologies used in high-frequency inverters, including half-bridge, full-bridge, and multilevel.

What are common high-frequency inverter circuit configurations?

Common high-frequency inverter circuit configurations include: Key design factors for high-frequency inverters: Switching frequency – Higher frequency allows smaller filter components but increases losses. Optimize based on tradeoffs. Filter components – Smaller inductors and capacitors possible at high frequencies. Balance size versus performance.

What determines the output frequency of a high-frequency inverter?

The output frequency depends on how fast the switches cycle on and off. Common high-frequency inverter circuit configurations include: Key design factors for high-frequency inverters: Switching frequency – Higher frequency allows smaller filter components but increases losses. Optimize based on tradeoffs.

How much does a high frequency inverter weigh?

That unit (Phocos PSW-H 5kw/120v) weighs around 110 lbs. I'm also considering it for my off-grid build, but I believe high frequency inverters generally weigh less and can double power on a surge for a couple seconds.

Related Articles

-

The important components of all-vanadium liquid flow battery are

The important components of all-vanadium liquid flow battery are

-

How many components can be connected in series with a micro inverter

How many components can be connected in series with a micro inverter

-

Communication base station inverter grid-connected components

Communication base station inverter grid-connected components

-

12v inverter main components

12v inverter main components

-

Inverter svg function photovoltaic components

Inverter svg function photovoltaic components

-

How many components can a 40kw inverter carry

How many components can a 40kw inverter carry

-

Large-scale high-frequency inverter

Large-scale high-frequency inverter

-

N-type double-sided double-glass high-efficiency components

N-type double-sided double-glass high-efficiency components

-

Components of wind turbine cabinet in communication base station

Components of wind turbine cabinet in communication base station

-

The relationship between energy storage batteries and components

The relationship between energy storage batteries and components

Commercial & Industrial Solar Storage Market Growth

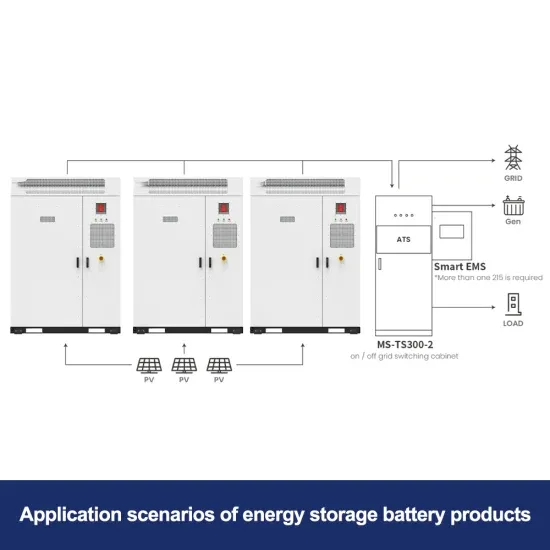

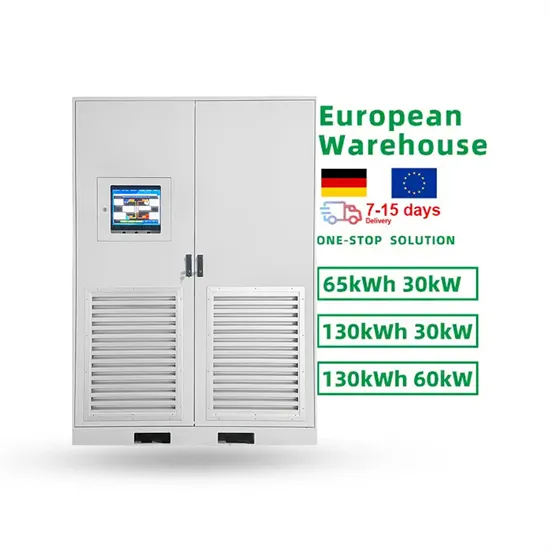

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

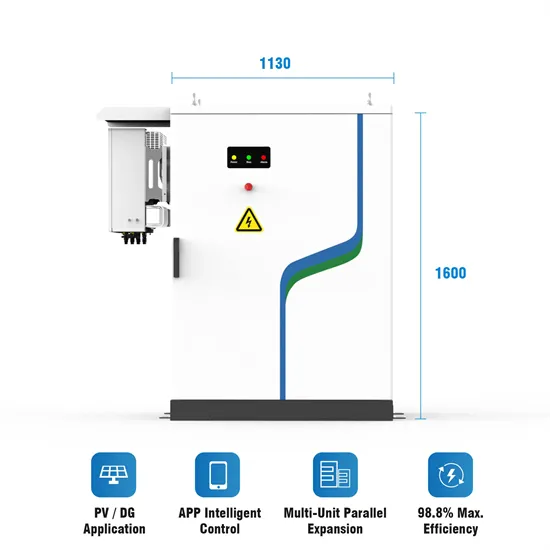

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.