How To Clean Battery Corrosion — Be A Cleaner

Aug 15, 2025 · Dry thoroughly before reassembling. Prevent future corrosion: Remove batteries from unused devices, use quality batteries, and store them correctly. Main Query Answer To

Get Started

Battery Rack | External Battery Racks | Battery

Jul 23, 2023 · Explore the best battery racks and cabinets for power system reliability. Learn how they help store, organize and secure batteries in

Get Started

How to Evaluate the Quality of a Battery: A Comprehensive

Here are several key factors to help you make an informed decision. 1. Capacity: The Core Metric of Battery Energy Storage. Capacity is a fundamental measure of battery performance,

Get Started

Battery Pack EOL Test: Ensure Safety

Jan 21, 2025 · Dynamic Load Testing: Simulating real-world conditions, this step assesses the battery''s response to varying loads, ensuring reliability during

Get Started

Battery Testing Procedures: Importance,

Sep 18, 2023 · To ensure that these batteries deliver the expected results, we must regularly test and maintain them. In this article, we will explore battery

Get Started

How to Test a Battery Before and After

Nov 8, 2024 · Learn How to Test a Battery Before and After Reconditioning. Ensure your batteries are performing well with these simple testing methods.

Get Started

Understanding the Different Types of Battery Test Equipment

Whether you are a manufacturer, researcher, or technician, selecting the right battery test equipment can significantly impact the quality and reliability of your batteries.

Get Started

Learn About Batteries

Batteries as Power Source Studies the battery in portable and stationary applications as well as in electric powertrains. We look at the kinetic power and cost of the battery in comparison to

Get Started

Battery Inspection Checklist

Oct 10, 2024 · Regular inspections help to prevent unexpected failures, decrease downtime, and ensure the battery runs at its full capacity. This checklist

Get Started

How to distinguish the quality of batteries?

5 days ago · How to Tell the Difference Between Good and Bad Batteries When it comes to batteries, quality matters—a lot. A subpar battery can leave you stranded with a dead device,

Get Started

How to test batteries number of cycles (manufacturing quality

Oct 13, 2024 · He told me that buying batteries for automotive-grade reliability (and that will involve mostly how well they work after hundreds of cycles) involves intense cycle testing,

Get Started

What are the Steps in Battery Testing? A Complete Guide

May 6, 2025 · How to use a battery test chamber for battery testing? Battery test chambers mimic extreme environmental conditions, temperature, humidity, and pressure, to test the batteries

Get Started

Inspecting your primary batteries: what you

Apr 5, 2023 · When it comes to batteries, there are a number of quick checks that are often performed during incoming inspection: Checking the box for damage

Get Started

Step-by-Step Battery Capacity Testing Procedure

May 23, 2024 · With our step-by-step procedure, you''ll learn how to precisely evaluate battery capacity. Discover key tools, techniques, & best practices for

Get Started

Most Accurate Way To Test A Battery

Oct 16, 2023 · Resistance Testing: Resistance testing offers the most insight into the condition of the battery''s internal components, which can be especially

Get Started

The Ultimate Guide to Lithium-Ion Battery

Mar 21, 2025 · Discover the importance of lithium-ion battery storage cabinets for safe battery storage and charging. Learn best practices, key features, and

Get Started

Battery Inspection Checklist

Oct 10, 2024 · This detailed Battery Inspection Checklist ensures battery performance and safety. This checklist, which includes both visual and

Get Started

Battery Testing Methods Across Key Industries

Jan 9, 2025 · Battery testing is crucial for verifying: Performance: Ensures the battery meets its stated capacity and energy delivery. Safety: Identifies

Get Started

How To Test Your Car''s Battery Health At Home

Jul 3, 2024 · The car battery plays an important role in the operation of the electrical components in the car. It is needed to start the car, run the air

Get Started

How to Test a Lithium Cell Battery: A Step-by

Wondering how to test a lithium cell battery? Follow this beginner-friendly guide to check voltage, capacity, and more while ensuring safety and accuracy.

Get Started

How EV Batteries Are Tested | IMI

Oct 18, 2023 · Testing also provides data on how batteries degrade over time and how to improve their longevity. Kinds of battery tests Formulating a test

Get Started

Battery Production | AVL

Aug 18, 2025 · To ensure that batteries deliver optimal performance over the longest possible lifetime while meeting strict safety standards, we have developed the AVL Battery TS™ End

Get Started

Step-by-Step Guide for Lithium Battery FCT Testing

Nov 28, 2024 · Discover how to test lithium batteries with our step-by-step guide. Master FCT testing techniques and boost your skills today!

Get Started

Lithium Battery Testing Requirements in India

Oct 1, 2024 · A Detailed Guide to Lithium Battery Testing Requirements in India In recent years, India has experienced a rapid surge in demand for lithium-ion batteries. This growth is driven

Get Started

Techniques for Battery Quality Control in Production

Apr 28, 2025 · In practice, an arsenal of battery QC techniques is the best defence against battery quality issues in the field. 1. Cycling and storage tests. Nearly every battery scientist and

Get Started

Exploring Battery Testing Standards: A

Apr 8, 2024 · Battery Testing Standards play a pivotal role in ensuring the safety, reliability, and performance of batteries in electric and hybrid vehicles. These

Get Started

Battery Testing Procedure

Jan 10, 2025 · Discover the step-by-step battery testing procedure, including how to measure voltage, capacity, and internal resistance. Using this

Get Started

Battery Test Methods

Apr 26, 2017 · Common test methods include time domain by activating the battery with pulses to observe ion-flow in Li-ion, and frequency domain by

Get Started

How We Test the Quality of Batteries We Sell at

Our battery analyzer can test up to 48 batteries at once. We work with battery engineers from around the world to constantly raise our quality bar. We

Get Started

What Are The Three Basic Battery Tests?

Dec 20, 2024 · What Are The Three Basic Battery Tests? A battery is a chemical mechanism designed to provide standby power to critical equipment. It is comprised of an array of cells

Get Started

Battery Testing 101: An Ultimate Guide

Aug 5, 2023 · Do you know that energy storage system testing is a hot topic today? In so-called "battery testing", they range from small portable batteries

Get Started

Proper Battery Testing Steps & Procedure

May 22, 2023 · The steps in battery testing involve a visual inspection for physical damage, a voltage check to make sure the battery is within a normal operating

Get Started

How to Test for Battery Discharge: A Comprehensive Guide

Dec 16, 2024 · Testing for battery discharge is a crucial process to determine the health and performance of a battery. Whether you''re using batteries for electric vehicles, solar power

Get Started

6 FAQs about [How to test the quality of batteries in the battery cabinet]

How do you test a lithium ion battery?

Common test methods include time domain by activating the battery with pulses to observe ion-flow in Li-ion, and frequency domain by scanning a battery with multiple frequencies. Advanced rapid-test technologies require complex software with battery-specific parameters and matrices serving as lookup tables.

Why are analytical techniques important in battery inspection?

These procedures are central to battery inspection workflows, enabling labs to deliver consistent results with traceability and confidence. Even with robust QA protocols, batteries can fail due to misuse, environmental exposure, or material degradation. Analytical techniques play a key role in:

What makes a good battery test?

Well-developed battery test technologies must recognize all battery conditions and provide reliable results, even if the charge is low. This is a demanding request as a good battery that is only partially charged behaves in a similar way to a faded pack that is fully charged.

What is battery quality control?

Explore battery quality control techniques used in lithium-ion battery testing, failure analysis, and performance validation across the battery lifecycle. As lithium-ion batteries become integral to technological innovation, quality control has emerged as a key discipline in ensuring their safety, reliability, and performance.

How do you know if a battery is good?

A battery’s performance under different temperature and humidity conditions is another important criterion for evaluating its quality. High-quality batteries typically function well across a wide range of temperatures, maintaining good performance in both the freezing cold of winter and the scorching heat of summer.

How do you test a car battery?

Capacity Testing: Verifies the battery’s ability to store and deliver energy. Cycle Life Testing: Evaluates how many charge-discharge cycles the battery can endure. Thermal Testing: Examines performance under varying temperature conditions to avoid overheating. Drop Tests: Assess battery resilience against physical impacts. 2. Automotive Industry

Related Articles

-

How many batteries are there in the DC battery cabinet

How many batteries are there in the DC battery cabinet

-

How to replace two sets of batteries in the battery cabinet

How to replace two sets of batteries in the battery cabinet

-

How to replace batteries in battery cabinet ESS power base station

How to replace batteries in battery cabinet ESS power base station

-

How to configure battery wind power in battery cabinet

How to configure battery wind power in battery cabinet

-

Zagreb energy storage battery cabinet test

Zagreb energy storage battery cabinet test

-

How much electricity does the battery cabinet have

How much electricity does the battery cabinet have

-

New Energy Battery Cabinet Safety Test

New Energy Battery Cabinet Safety Test

-

How to list the eps battery cabinet

How to list the eps battery cabinet

-

Does the n-type battery cabinet include lithium batteries

Does the n-type battery cabinet include lithium batteries

-

Test report of communication high voltage energy storage battery cabinet

Test report of communication high voltage energy storage battery cabinet

Commercial & Industrial Solar Storage Market Growth

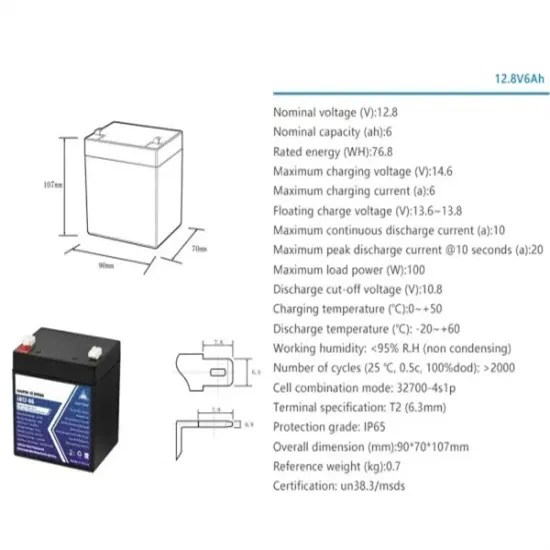

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.