Battery Energy Storage System Cooling

Kooltronic offers innovative cooling solutions for battery cabinets and electrical enclosures used in renewable energy storage systems. Click to learn more.

Get Started

Top-Rated Cooling Systems for Battery Cabinets

Could your current cooling system handle the 500W/cm² heat flux of next-gen silicon anode batteries? With 83% of new battery installations occurring in tropical regions, the industry must

Get Started

Which Cooling Technology Is Best for EV

May 8, 2025 · Importance of Battery Cooling System Advances in battery technology have increased power output and reduced charging frequency in

Get Started

Battery Cabinet Cooling Requirements | HuiJue Group E-Site

Battery cabinet cooling requirements have become the linchpin of modern energy infrastructure. A single temperature spike beyond 45°C can trigger irreversible capacity loss – but is forced air

Get Started

Cabinet Cooling: A Key Aspect in Energy Storage Systems

Apr 29, 2025 · In the realm of energy storage systems, cabinet cooling stands as a crucial element that significantly impacts the performance, reliability, and lifespan of the entire setup.

Get Started

A novel thermal management system for lithium-ion battery

Sep 1, 2023 · The safety, lifespan and performance of lithium-ion battery are closely related to its working temperature. A large amount of heat will be generated inside the battery during

Get Started

Battery Energy Storage System Cooling

Sep 30, 2024 · Kooltronic offers innovative cooling solutions for battery cabinets and electrical enclosures used in renewable energy storage systems. Click to

Get Started

Application of Refrigerant Cooling in a Battery

Jun 5, 2024 · Battery thermal management (BTM) is crucial for the lifespan and safety of batteries. Refrigerant cooling is a novel cooling technique that is

Get Started

Thermal performance of direct two-phase refrigerant cooling for lithium

Jun 5, 2020 · An efficient battery thermal management system is essential for lithium-ion batteries with high cooling performance and long lifetime. The objective of this study is to investigate the

Get Started

Comparative analysis of battery electric vehicle thermal

Dec 11, 2021 · Due to increasing regulation on emissions and shifting consumer preferences, the wide adoption of battery electric vehicles (BEV) hinges on research and development of

Get Started

Thermal runaway behaviour and heat generation

Mar 1, 2024 · The findings of this study provide insights into the TR behaviour of a marine battery cabinet and its influence on heat generation as well as guidance for the thermal management

Get Started

Battery Cooling Methods in Electric Cars_XNmotors

Aug 16, 2025 · Conclusion The battery cooling method is a key factor in ensuring the smooth, safe, and efficient operation of an electric car. As technology evolves, automakers continue to

Get Started

Research on fast-charging battery thermal management

Jul 20, 2023 · Refrigerant direct cooling technology is a new type of power battery phase change cooling system, which uses the refrigerant in automotive air conditioners as a cooling medium

Get Started

Liquid Cooling Battery Cabinet: Maximize Efficiency Now

Excessive heat can significantly degrade battery health, reduce efficiency, and pose serious safety risks. To address this, the industry is increasingly turning to advanced solutions like the

Get Started

What is liquid-cooled battery cooling? – TYCORUN

Apr 1, 2022 · The principle of liquid-cooled battery heat dissipation is shown in Figure 1. In a passive liquid cooling system, the liquid medium flows through

Get Started

Experimental and numerical investigation of a composite

Mar 1, 2025 · Traditional air-cooled thermal management solutions cannot meet the requirements of heat dissipation and temperature uniformity of the commercial large-capacity energy storage

Get Started

Comprehensive comparison study on battery thermal

Jun 1, 2025 · • Performance of three thermal management methods under high-rate was investigated. • Immersion cooling shows the best performance in both battery heating and

Get Started

Immersion cooling technology development status of

At the same time, the utilization of waste heat in the data center immersion cooling system is discussed, providing readers with extensive and detailed background knowledge of data

Get Started

BATTERY HEATING

4 days ago · Conductive heating (or direct heating) refers to placing the electric heaters or heating plates containing electric heating wires at the surface of

Get Started

Comparison of different cooling methods for lithium ion battery

Feb 5, 2016 · Choosing a proper cooling method for a lithium-ion (Li-ion) battery pack for electric drive vehicles (EDVs) and making an optimal cooling control stra

Get Started

What Are the Popular Battery Heat Exchange Solutions in the

Aug 13, 2025 · Explore the different types of battery thermal management systems with a focus on liquid cooling technologies. Learn how to choose and customize the optimal heat exchange

Get Started

Decoupling control of an integrated direct cooling thermal

Apr 1, 2024 · As the requirement for Li-ion battery thermal management system (TMS) in electric vehicles (EVs) rises, an integrated direct cooling thermal management system with high

Get Started

Advances in direct cooling battery thermal management

Aug 8, 2024 · 直冷电池热管理技术利用制冷剂蒸发吸热原理,可实现高效冷却效率,相较于传统液冷和风冷系统,直冷系统具有结构更紧凑、响应速度更快的显著特征。 通过梳理近期相关文

Get Started

A Review of Cooling Technologies in Lithium-Ion

Dec 18, 2023 · The power battery is an important component of new energy vehicles, and thermal safety is the key issue in its development. During

Get Started

Advances in battery thermal management for electric

Feb 1, 2025 · One of the major challenges currently facing electric vehicles (EVs) is the effective thermal management of their battery packs, which significantly impacts both battery

Get Started

Study on performance effects for battery energy storage

Feb 1, 2025 · The purpose of this study is to develop appropriate battery thermal management system to keep the battery at the optimal temperature, which is very important for electrical

Get Started

Battery cabinet heating method diagram video

In this article we will discuss some tips on how to design the best battery cabinet: 1, How to determine the battery backup capacity in the battery cabinet Download scientific diagram |

Get Started

Recent Progress and Prospects in Liquid Cooling

Aug 1, 2023 · The performance of lithium-ion batteries is closely related to temperature, and much attention has been paid to their thermal safety. With

Get Started

6 FAQs about [Battery cabinet direct heating and cooling technology]

What are the different thermal management technologies for EV batteries?

Current thermal management technologies for EV batteries include air cooling , , , , liquid cooling , , and phase change material cooling , . The predominant method for lithium-ion battery thermal management in contemporary EVs involves liquid cooling plates .

How is a power battery thermally managed?

The power battery is thermally managed using liquid as a medium, including a liquid cooling system and a liquid heating system. Liquid-cooled battery heat dissipation is developed under the background that air-cooled battery cooling cannot meet the expected heat dissipation effect.

How are lithium ion batteries cooled?

The predominant method for lithium-ion battery thermal management in contemporary EVs involves liquid cooling plates . Researchers worldwide have extensively studied liquid cooling methods for these batteries.

Why is thermal management important for EV batteries?

Therefore, the thermal management strategy for EV batteries is essential for ensuring vehicle safety and extending its service life. Current thermal management technologies for EV batteries include air cooling , , , , liquid cooling , , and phase change material cooling , .

Can a liquid cooling system reduce battery peak temperatures?

Wang et al. designed a novel liquid cooling system based on a thermal silicon plate, focusing on a lithium-ion battery. Their findings indicated that increasing the number of thermal silicon plates and liquid channels led to reduced battery peak temperatures. Additionally, the flow direction minimally impacted cooling performance.

How does an indirect contact liquid cooling system work?

In the indirect contact liquid cooling system, the cooling liquid flows in the pipe and contacts the battery through a medium such as fins or heat sinks to take away heat, thereby cooling the battery. For cylindrical batteries, it can also be set to a ring-jacketed structure.

Related Articles

-

Battery Cabinet Cooling Technology Comparison

Battery Cabinet Cooling Technology Comparison

-

Energy storage liquid cooling battery cabinet technology development

Energy storage liquid cooling battery cabinet technology development

-

Zhixiang Technology New Energy Battery Cabinet

Zhixiang Technology New Energy Battery Cabinet

-

Battery cabinet cooling system ESS power base station

Battery cabinet cooling system ESS power base station

-

Vanuatu outdoor communication battery cabinet factory direct sales shop

Vanuatu outdoor communication battery cabinet factory direct sales shop

-

Zagreb lithium battery station cabinet manufacturer direct sales store

Zagreb lithium battery station cabinet manufacturer direct sales store

-

Liquid cooling of energy storage battery cabinet

Liquid cooling of energy storage battery cabinet

-

Patented technology of energy storage cabinet battery

Patented technology of energy storage cabinet battery

-

Port of Spain lithium battery station cabinet factory direct sales

Port of Spain lithium battery station cabinet factory direct sales

-

New energy battery cabinet photovoltaic water cooling

New energy battery cabinet photovoltaic water cooling

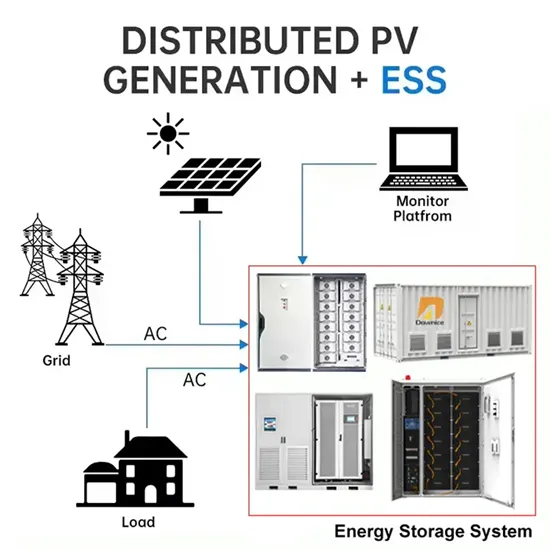

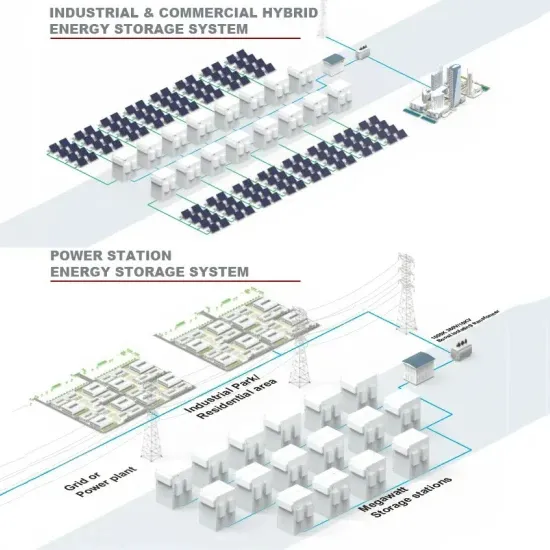

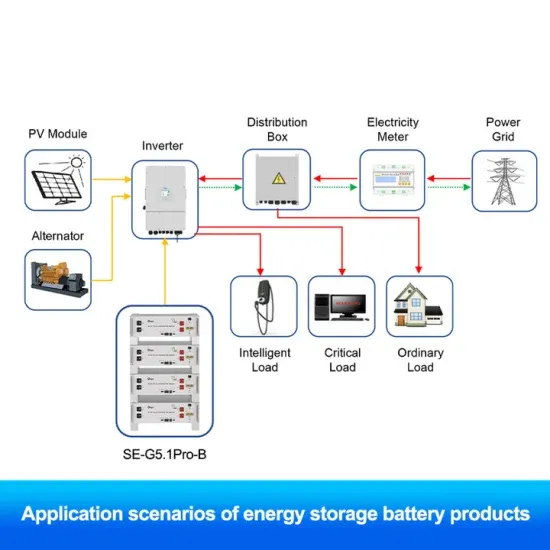

Commercial & Industrial Solar Storage Market Growth

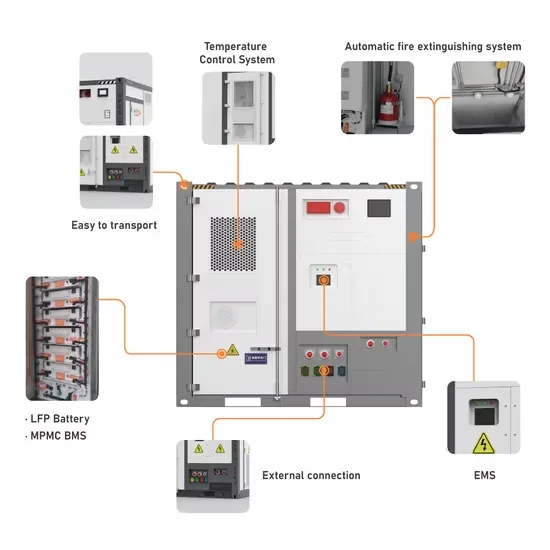

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.