Battery Shells Aluminium Plate Sheet | Haomei

Aug 2, 2024 · Aluminum plate sheets have emerged as a key component in the construction of battery shells, contributing to the evolution of energy storage

Get Started

Laminated tin–aluminum anodes to build practical aqueous aluminum batteries

Feb 1, 2024 · Aqueous aluminum metal batteries (AAMBs) have emerged as promising energy storage devices, leveraging the abundance of Al and their high energy density. However,

Get Started

Advancing aluminum-ion batteries: unraveling the charge storage

Nov 18, 2024 · Since their inception, lithium-ion batteries (LIBs) have revolutionized electrical energy storage, paving the way for the widespread adoption of electric vehicles and the

Get Started

Aluminium-Air Batteries: Transforming Energy Storage with

Dec 6, 2024 · This combined with the best packing method gives us a high performing Aluminum-Air cell/battery. Unlike electrical recharging, Aluminum-air batteries need a mechanical

Get Started

Electrolyte design for rechargeable aluminum-ion batteries:

Nov 1, 2023 · Aluminum-ion batteries (AIBs) are a promising candidate for large-scale energy storage due to the merits of high specific capacity, low cost, light weight, good safety, and

Get Started

Cold Plates in EV & Energy Storage: Types, Applications

Jun 25, 2025 · Explore the 4 main types of liquid cooling plates used in EVs and battery energy storage systems. Learn their advantages, application scenarios.

Get Started

Aluminum batteries: Unique potentials and addressing key

Jun 15, 2024 · Lithium-ion batteries (LIBs), currently leading the field in rechargeable battery technology (including vehicles like cars and bicycles, electric scooters, drones, as well as

Get Started

5 Optimization Guidelines for Energy Storage Liquid Cooling Plate

Jul 24, 2025 · The 500Ah+ large energy storage battery cell technology is rapidly emerging, demanding significantly higher efficiency from thermal management systems. Liquid cooling

Get Started

Long-term, heat-based energy storage in

Aug 19, 2022 · The concept is fundamentally different from traditional methods of energy storage such as batteries, hydrogen or synthetic fuels, and uses

Get Started

Energy storage aluminum plate

New energy vehicle liquid cooling plate and energy storage battery liquid cooling plate usually use 3003 aluminum plate as raw material. 3003 aluminum plate is a kind of aluminum manganese

Get Started

The Critical Role of Aluminum Plates in Energy Storage Batteries

Summary: Aluminum plates are revolutionizing energy storage systems by enhancing battery efficiency, thermal management, and durability. This article explores their applications in

Get Started

Application and process analysis of aluminum

Apr 25, 2025 · In-depth analysis of the core applications of aluminum alloys in the field of new energy, covering the material selection, processing technology

Get Started

A Review on the Recent Advances in Battery

Nonetheless, in order to achieve green energy transition and mitigate climate risks resulting from the use of fossil-based fuels, robust energy storage

Get Started

Aluminum batteries: Opportunities and challenges

Jun 1, 2024 · This article explores the potential and challenges of aluminum batteries, focusing on their applications, benefits, and limitations in energy storage.

Get Started

Square aluminum shell lithium-ion battery energy storage

ACEIN Gathering Square Shell Energy Storage Cells is a technology enterprisespecializing in the design,development,manufacturing and sales of energy storage lithium-ion cells and battery

Get Started

Aluminum Air Battery Materials and Assembly

Apr 24, 2025 · An aluminum air battery uses aluminum and air to generate power. Learn its materials, assembly steps, and tips to boost energy output and

Get Started

3005 Aluminum Plate for Battery Shell | Haomei Aluminum

5 days ago · Whether in portable electronic devices, energy storage batteries, electric vehicles, or other fields that require battery protection, 3005 aluminum alloy can effectively protect the

Get Started

Aluminum Extrusions for Energy Storage System (ESS): A

Apr 19, 2025 · What are Aluminum Extrusions? 1. ESS Battery Tray Frames. 2. Battery Enclosure Profiles. 3. Modular Battery Compartment Extrusions. 4. Liquid Cooling Plates for ESS. 5.

Get Started

Aluminum-ion battery outperforms lithium

Feb 3, 2025 · The aluminum-ionbattery''s extended lifespan reduces replacement frequency and costs for consumers and industries, making it ideal for large-scale and grid-scale energy

Get Started

Aluminum Extrusions for Energy Storage System (ESS): A

Apr 19, 2025 · As the world transitions towards cleaner and more sustainable energy solutions, the demand for efficient, scalable, and reliable energy storage systems (ESS) has surged. A

Get Started

Aluminum Plate for Battery Shell Market by End Use Industry

Aluminum plate innovation, from refined alloy chemistries to advanced rolling and surface treatment techniques, underpins this evolution. By enabling enhanced heat dissipation,

Get Started

Optimized design of liquid-cooled plate structure for flying

Sep 1, 2024 · This article focuses on the optimization design of liquid cooling plate structures for battery packs in flying cars, specifically addressing the high power heat generation during

Get Started

Do All Battery Packs Need Aluminum End Plates?

Jun 11, 2025 · When designing battery packs—especially for energy storage (ESS) or EV applications—one common question is whether aluminum end plates are necessary. Let''s

Get Started

Multi-objective topology optimization design of liquid

Feb 1, 2025 · Developing energy storage system based on lithium-ion batteries has become a promising route to mitigate the intermittency of renewable energies and improve their

Get Started

Solid-State Aluminum-Ion Battery Demonstrates

Jan 26, 2025 · As researchers continue to improve and refine aluminum-ion battery technology, it could become a cornerstone of the sustainable energy

Get Started

Aluminum Battery Solutions | Constellium

6 days ago · Constellium offers complete aluminum solutions—rolled and extruded—for modern battery systems, including foils, connectors, thermal and enclosure components. Designed to

Get Started

Battery Aluminum Foil Materials for Lithium-ion

Aug 17, 2025 · HDM is the leading supplier of battery aluminum foil materials for lithium-ion energy storage technology in the Asia-Pacific region.

Get Started

New Energy Vehicle Power Battery Aluminum

Jul 31, 2025 · Chalco''s production of power battery aluminum trays mostly uses 6-series 6061 aluminum plate as the raw material for battery aluminum trays,

Get Started

Battery Shells Aluminium Plate Sheet | Haomei

Aug 2, 2024 · Battery Shells Aluminium Plate Sheet Advantages Common Thickness and Specifications of Battery Shells Aluminum Plate Sheets Typical

Get Started

Top 10 Companies in the Anti-Explosive Cover Plate for Lithium Battery

Jun 21, 2025 · The Global Anti-Explosive Cover Plate for Lithium Battery Market was valued at USD 849 Million in 2024 and is projected to reach USD 1,529 Million by 2032, growing at a

Get Started

Aluminium lon Battery Price, Aluminum lon

Sinopoly Aluminum Prismatic LFP Cells boast exceptional battery performance, featuring high energy density, along with comprehensive protection

Get Started

6 FAQs about [Aluminum plate for energy storage battery]

Are aluminum-ion batteries a good choice for energy storage devices?

Aluminum-ion batteries (AIBs) are recognized as one of the promising candidates for future energy storage devices due to their merits of cost-effectiveness, high voltage, and high-power operation. Many efforts have been devoted to the development of cathode materials, and the progress has been well summarized in this review paper.

What material is used in power battery aluminum trays?

Chalco's production of power battery aluminum trays mostly uses 6-series 6061 aluminum plate as the raw material for battery aluminum trays, which can meet the characteristics of high precision, corrosion resistance, high temperature resistance, and impact resistance to protect the battery core.

Which aluminum alloy is used in power batteries?

Aluminum alloy is a commonly used material for power batteries, and there is an urgent need to focus on research, development, and upgrading of products and alloy materials. At present, the conventional aluminum alloys used in power batteries mainly include 1-series, 3-series, 5-series, and 6-series.

What are energy power battery shells made of?

The new energy power battery shells on the market are mainly square in shape, usually made of 3003 aluminum alloy using hot rolled deep drawing process. Depending on the design requirements of the power battery, the thickness and width can be customized.

What is a power battery casing made of?

The material of the power battery casing is generally made of aluminum casing, because the aluminum casing has excellent lightweight structure, good thermal conductivity, and is safer and more durable.

What is a battery pack shell?

Battery pack shell: the external shell used to secure and protect the battery module. The parts that may use aluminum alloy materials include power battery casing wall panels, brackets, etc. Connector: a component used to connect battery modules and other components.

Related Articles

-

Aluminum acid energy storage battery

Aluminum acid energy storage battery

-

Aluminum battery energy storage box manufacturers

Aluminum battery energy storage box manufacturers

-

Aluminum battery energy storage

Aluminum battery energy storage

-

Portugal Porto aluminum acid energy storage battery pump manufacturer

Portugal Porto aluminum acid energy storage battery pump manufacturer

-

Roma Aluminum Alloy Battery Energy Storage Container Price

Roma Aluminum Alloy Battery Energy Storage Container Price

-

South Tarawa aluminum acid energy storage battery brand

South Tarawa aluminum acid energy storage battery brand

-

Aluminum battery energy storage system

Aluminum battery energy storage system

-

Liquid flow battery energy storage container selling price

Liquid flow battery energy storage container selling price

-

Energy storage cabinet battery installation time

Energy storage cabinet battery installation time

-

Dakar battery energy storage manufacturing company

Dakar battery energy storage manufacturing company

Commercial & Industrial Solar Storage Market Growth

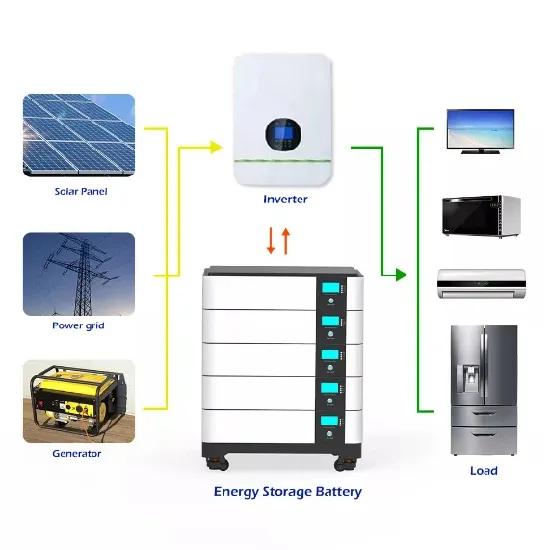

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.