Container energy storage air duct design

The invention discloses a low-pressure-loss main air duct structure of an energy storage container, which relates to the technical field of container energy storage and comprises a T

Get Started

Container energy storage box design scheme

The Container Energy Storage System is securely packaged to ensure that it arrives to its destination in good condition. The system is individually packaged in a box or crate. All parts

Get Started

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · The air-cooling system is of great significance in the battery thermal management system because of its simple structure and low cost. This study analyses the thermal

Get Started

How big is the air duct design of the energy storage

The chief requirements of an What is energy storage container? SCU uses standard battery modules, PCS modules, BMS, EMS, and other systems to form standard containers to build

Get Started

how big is the air duct design of the energy storage container

HVAC Ductwork Design Guide (Layout, Duct Size & CFM) 1. Calculate the CFM for Each Room. Most HVAC units are designed to have a 400 CFM of airflow for every 12000 BTU or 1 ton of

Get Started

Thermal Management for a Stadium Power Supply

Apr 16, 2024 · 8 K. Furthermore, a rack-level thermal management scheme is proposed to effectively reduce the thermal deviation of the container electric energy storage system and

Get Started

Design and optimization of the cooling duct system for the

A personalized uniform air supply scheme in the form of "main duct + riser" is proposed for the energy storage battery packs on the left and right sides of the container.

Get Started

energy storage container air duct structure picture

A thermal management system for an energy storage battery container The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have

Get Started

HOW BIG IS THE AIR DUCT DESIGN OF THE ENERGY

Here''s how to install air ducts Energy Storage Container integrated design for easy delivery; Control the cooling and heating system of the air conditioner through thermal management

Get Started

Cooling air duct design for container energy storage battery

The practical model of the energy storage container is shown in Fig. 1, and the geometrical model of the localized air supply duct within the container is depicted in Fig. 2 ve vertical ducts

Get Started

How to design the air duct of energy storage module

At present, energy storage systems mostly adopt the thermal management scheme of air conditioning + cooling duct air supply. The air duct is mainly divided into serial ventilation and

Get Started

OPTIMIZING FORCED AIR-COOLING

Jun 30, 2023 · Forced air-cooling technology plays a vital role in energy storage systems, ensuring efficient cooling and optimal performance. Customized air

Get Started

How big is the air duct design of the energy storage container

Design and optimization of the cooling duct system for the A personalized uniform air supply scheme in the form of "main duct + riser" is proposed for the energy storage battery packs on

Get Started

Optimized thermal management of a battery energy-storage

Jan 1, 2023 · Inspired by the ventilation system of data centers, we demonstrated a solution to improve the airflow distribution of a battery energy-storage system (BESS) that can

Get Started

Energy storage battery air duct design

Airflow reorganization and thermal management in a large-space battery Airflow reorganization and thermal management in a large-space battery energy storage container using perforated

Get Started

Coupling simulation of the cooling air duct and

Jun 5, 2023 · The air-cooled battery thermal management system (BTMS) is a safe and cost-effective system to control the operating temperature of battery

Get Started

CN218731240U

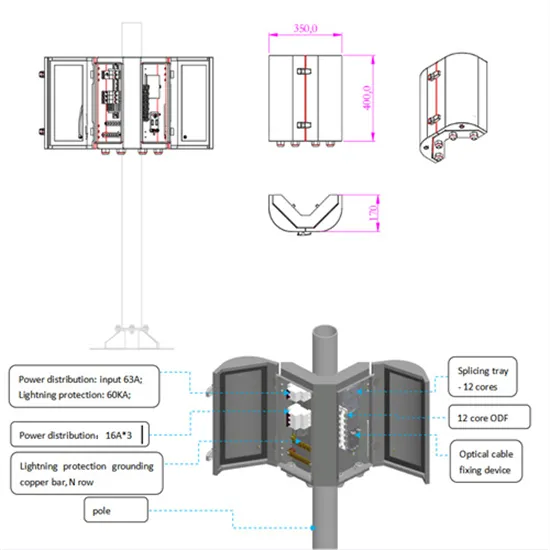

The utility model discloses an energy storage container wind channel, its technical scheme main points are: the air-cooled battery pack box comprises an air-cooled case, wherein a container

Get Started

Maximizing efficiency: exploring the crucial role of ducts in air

Jan 29, 2025 · The present work reviews the critical role of duct design in enhancing the efficiency of air-cooled LIBs, by comparing symmetrical and asymmetrical duct configurations.

Get Started

Energy storage battery cabinet air duct design

A personalized uniform air supply scheme in the form of "main duct + riser" is proposed for the energy storage battery packs on the left and right sides of the container.

Get Started

Understanding the Air Duct Design in Air-Cooled Energy Storage

Jun 11, 2025 · Air duct design in air-cooled energy storage systems (ESS) refers to the engineering layout of internal ventilation pathways that guide airflow for optimal thermal

Get Started

Forced air-cooling technology is mature, and air

Feb 27, 2023 · This article discusses the design of forced air-cooling technology for energy storage systems, with a focus on air duct design and control

Get Started

Simulation analysis and optimization of containerized energy storage

Sep 10, 2024 · The study first explores the effects of different air supply angles on the heat transfer characteristics. Second, the evaluation indexes of heat removal efficiency, air

Get Started

Energy Storage Containers: How Battery Rack Air Duct Design

As renewable energy adoption accelerates, the design of energy storage containers has become sort of a make-or-break factor for project viability. Let''s unpack why the marriage of battery

Get Started

Multi-Level Thermal Modeling and Management

Jun 2, 2025 · The air duct design scheme met the thermal management design requirements, and the air duct flow line is shown in Figure 4 b. The Fluent

Get Started

某型集装箱储能电池组冷却风道设计及优化

Jun 1, 2020 · 关键词: 集装箱, 储能电池, 冷却风道, 数值模拟, 优化 Abstract: This study takes a certain type of container energy storage system as the research

Get Started

(PDF) Thermal management research for a 2.5

Feb 13, 2023 · Thermal management research for a 2.5 MWh energy storage power station on airflow organization optimization and heat transfer influential

Get Started

An improved air supply scheme for battery energy

Nov 19, 2023 · It is demonstrated that air deflection is the main source of airflow inhomogeneity at the air outlets. The airflow uniformity is better when the baffles are added at the entrance and

Get Started

Air duct improved energy storage container

The utility model discloses an air duct improved energy storage container, which comprises a container, an air conditioner, an air duct and a battery rack, wherein the air conditioner, the air

Get Started

A thermal management system for an energy storage battery container

May 1, 2023 · The existing thermal runaway and barrel effect of energy storage container with multiple battery packs have become a hot topic of research. This paper innovatively proposes

Get Started

Airflow reorganization and thermal management in a

Nov 1, 2024 · The practical model of the energy storage container is shown in Fig. 1, and the geometrical model of the localized air supply duct within the container is depicted in Fig. 2.

Get Started

6 FAQs about [Energy storage container air duct design scheme]

What is a containerized energy storage battery system?

The containerized energy storage battery system comprises a container and air conditioning units. Within the container, there are two battery compartments and one control cabinet. Each battery compartment contains 2 clusters of battery racks, with each cluster consisting of 3 rows of battery racks.

Can CFD simulation be used in containerized energy storage battery system?

Therefore, we analyzed the airflow organization and battery surface temperature distribution of a 1540 kWh containerized energy storage battery system using CFD simulation technology. Initially, we validated the feasibility of the simulation method by comparing experimental results with numerical ones.

Where is the air supply duct located?

The air supply ducts are positioned directly above the battery racks, with six identically sized air conditioning vents along the duct sidewalls, opposite the partition. The control cabinet is situated on the left side of the battery compartments, while the air conditioning units are installed on the right side of the container. Fig. 1.

What is the best airflow distribution in a battery compartment?

Combined with the temperature distribution on the surface of the battery table and the final ranking results of each evaluation index, the airflow distribution in the battery compartment is most ideal when the air supply angle is 90° and the return air vent is at Z = 0.85 m on the side of the fire door. Table 7.

What is a containerized storage battery compartment?

The containerized storage battery compartment is separated by a bulkhead to form two small battery compartments with a completely symmetrical arrangement. The air-cooling principle inside the two battery compartments is exactly the same.

Are air cooling systems good for energy storage?

Air cooling systems, favoured for their low cost, simplicity, and space efficiency, are widely utilized in practical energy storage applications . However, they exhibit lower efficiency at high discharge rates and temperatures, resulting in uneven battery temperatures [16, 17].

Related Articles

-

Application analysis and design scheme of container energy storage cabinet

Application analysis and design scheme of container energy storage cabinet

-

Air duct design of air-cooled energy storage system

Air duct design of air-cooled energy storage system

-

Energy storage container air duct height specification

Energy storage container air duct height specification

-

Energy storage container design factory operation requirements

Energy storage container design factory operation requirements

-

Optimized design scheme for energy storage module

Optimized design scheme for energy storage module

-

Solar energy storage container wall design

Solar energy storage container wall design

-

Castries Energy Storage Industry Planning Scheme Design

Castries Energy Storage Industry Planning Scheme Design

-

Typical design scheme of energy storage booster station

Typical design scheme of energy storage booster station

-

Container battery energy storage ventilation

Container battery energy storage ventilation

-

How many meters is the energy storage container

How many meters is the energy storage container

Commercial & Industrial Solar Storage Market Growth

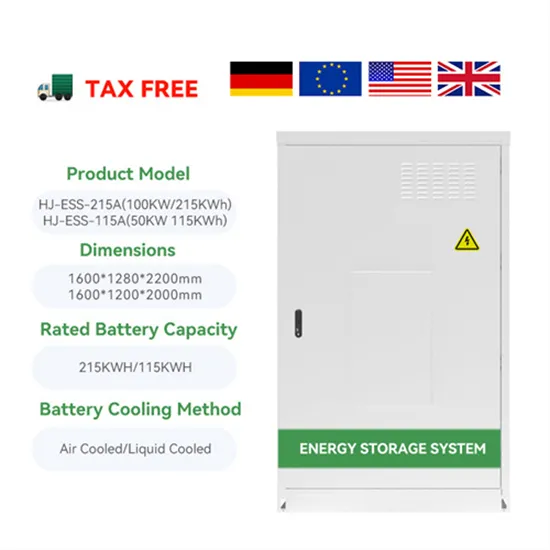

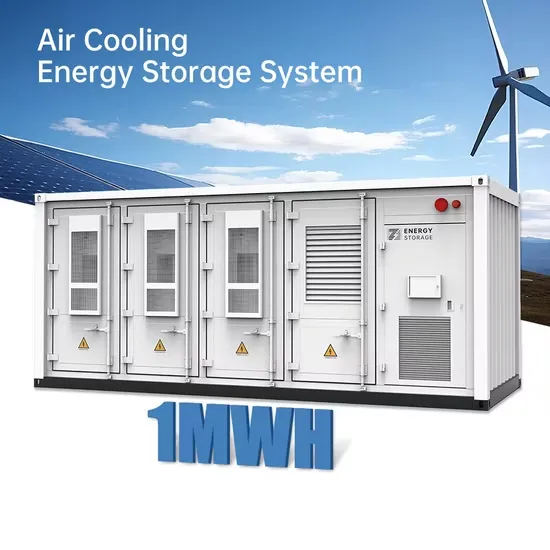

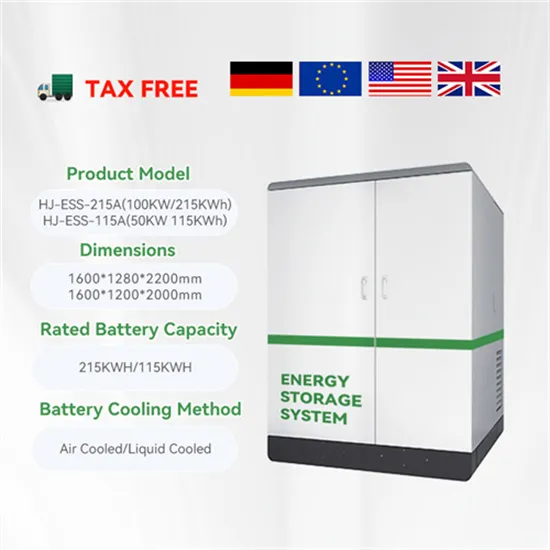

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.