Solar Panel Manufacturing: A Comprehensive

Aug 9, 2023 · Solar panel manufacturing is the process of producing photovoltaic (PV) panels used to capture energy from the sun and convert it into usable

Get Started

Photovoltaic glass production process

The invention discloses a photovoltaic glass production process which comprises the following steps: 1, taking out various materials in proportion; 2, grinding the raw materials into powder

Get Started

Window-Integrated PV Glass: The Future of Solar

Feb 19, 2025 · Photovoltaic (PV) glass stands at the forefront of sustainable building technology, revolutionizing how we harness solar energy in modern

Get Started

The solar cell wafering process

May 21, 2024 · Finally, the wafering process step, in combination with the material quality, defines the mechanical properties of the final solar cell, as the wafering process can damage the

Get Started

Glass washing challenges in thin-film Glass washing

May 21, 2024 · Introduction: the role of glass in thin-film photovoltaics While classic PV modules are produced in a production process of several steps by wiring crystalline silicon wafers, in

Get Started

Sustainable Management of Photovoltaic Waste

Jan 10, 2025 · The rapid expansion of photovoltaic (PV) technology as a source of renewable energy has resulted in a significant increase in PV panel waste,

Get Started

Production process and classification of

Nov 15, 2021 · At present, there are mainly the following two production processes for photovoltaic glass. (1) The production process of Gridfa glass

Get Started

Solar panel manufacturing process: from cell to

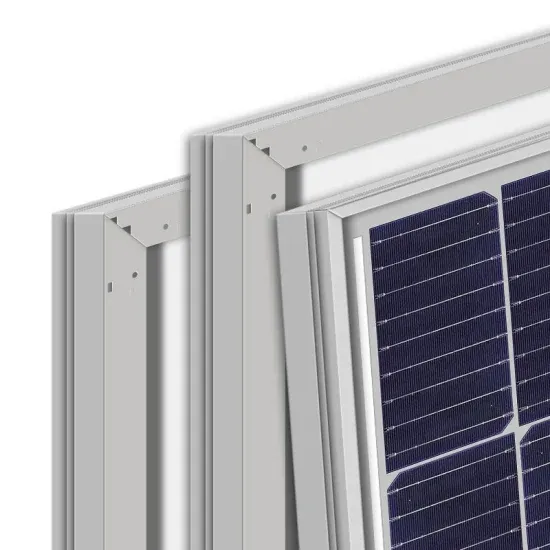

Solar panel lamination Sealed into ethylene vinyl acetate, they are put into a frame that is sealed with silicon glue and covered with a mylar back on the

Get Started

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · Production process of photovoltaic glass. The deep processing process of photovoltaic glass involves two steps: tempering and coating. The

Get Started

Solar Photovoltaic Glass Production Process

The production of photovoltaic glass involves several stages, from the preparation of raw materials to the final assembly of the glass panels. The first step in the production of

Get Started

How Are Solar Panels Made Step by Step

Jun 17, 2024 · How are solar panels made step by step? This detailed guide explains the entire solar panel manufacturing process, from silicon ingot to PV

Get Started

Solar Photovoltaic Manufacturing Basics

4 days ago · The manufacturing typically starts with float glass coated with a transparent conductive layer, onto which the photovoltaic absorber material is

Get Started

A Comprehensive Guide to Solar Panel

Solar Panel Manufacturing: Understanding the Process Here are the main steps that outline the solar panel manufacturing process: 1. Solar Cell Sorting Solar

Get Started

Solar Cell Manufacturing: A Comprehensive Guide

Overview Of Solar Cell Manufacturing Solar cell manufacturing is the process of producing solar cells, which are used to create photovoltaic (PV) modules. These modules are used to

Get Started

Manufacturing of Silicon Solar Cells and Modules

Jun 13, 2023 · This chapter highlights the "silicon wafer to PV module" journey, with all pertinent steps of optically and electrically augmenting each wafer explained in details. The steps of

Get Started

PV: mechanical treatment of glass

Mar 4, 2025 · Custom cutting Edge grinding and polishing These steps are crucial, as sharp edges and microcracks at the extremities can cause stress concentrations, leading to

Get Started

How Are Solar Cells Made? A Complete Guide

Sep 2, 2023 · Introduction to Solar Cells Solar cells, also known as photovoltaic cells, are made from silicon, a semi-conductive material. Silicon is sliced into

Get Started

PV Module Manufacturing

Aug 13, 2025 · Figure 1: PV module with 36 cells interconnected to form a series string. Figure 2: Schematic of the PV module manufacturing flow. The

Get Started

SOLAR PHOTOVOLTAIC GLASS FEATURES TYPE AND PROCESS

Photovoltaic glass is probably the most cutting-edge new solar panel technology that promises to be a game-changer in expanding the scope of solar. These are transparent solar panels that

Get Started

How is solar glass made? | NenPower

Mar 28, 2024 · HOW DOES THE QUALITY OF SOLAR GLASS AFFECT SOLAR PANEL PERFORMANCE? The quality of solar glass is crucial in determining

Get Started

Solar Panel Manufacturing Process Explained

Apr 29, 2023 · The Solar Panel Manufacturing Process The manufacturing process for solar PV panels typically involves several steps which include;

Get Started

The Solar Panel Manufacturing Process

Aug 19, 2025 · Solar panel manufacturing is a complex, multi-step process, involving a range of scientific disciplines and high precision procedures to turn

Get Started

The whole process of making photovoltaic panel glass

is the first step in the production of solar panels. This process involves the fabrication of PV cells,which ar made up of semiconductor materials such as silicon. The operator cuts the cel

Get Started

Flow Chart of the Solar Panel Manufacturing

May 18, 2024 · Explore a detailed flow chart of the solar panel manufacturing process, from raw silicon to finished panels. Unveil the steps of photovoltaic

Get Started

Solar Panel Production Process: A Complete Guide

5 days ago · 1. Purpose How are solar panels made? This document gives guidelines on the solar panel production process. It also gives details of the

Get Started

How to Make Photovoltaic Glass

How to Make Photovoltaic GlassIn today''s world, renewable energy sources are becoming increasingly important. One of the most innovative methods for harnessing solar energy is

Get Started

how to make photovoltaic glass › › Basengreen Energy

How is photovoltaic glass made? Photovoltaic glass is made using a process called "solar cell integration". This involves embedding photovoltaic cells into the glass during the

Get Started

Photovoltaic Automation Knowledge Base

Aug 17, 2025 · Photovoltaic Automation Knowledge Base - Module Automation Production Line Photovoltaic cell module is the core part of photovoltaic power

Get Started

IJRTI

Nov 22, 2022 · Here we have emphasized on complete panel manufacturing process viz. Manufacturing of PV Cell, different types of PV Cell, Solar Panels, Testing of Solar Panels,

Get Started

How is solar glass made? | NenPower

Mar 28, 2024 · How is solar glass made? 1. The manufacturing of solar glass involves several intricate processes. 2. The initial step is the selection and

Get Started

Introduction to deep processing of photovoltaic glass_Sinoy

The deep processing process of photovoltaic glass includes two steps: tempering and coating. Tempering aims to enhance the strength of the glass, while coating is to coat a layer of anti

Get Started

Solar Panel Manufacturing Process Explained

Mar 11, 2025 · Silicon wafer production is a careful process. Each step is important to make sure the wafers are high quality for use in technology.

Get Started

Basics of Solar Panel Manufacturing | Step-by

Jan 20, 2023 · The photovoltaic (PV) manufacturing process is the first step in the production of solar panels. This process involves the fabrication of PV cells,

Get Started

Powering the Future: Inside the Solar PV Cell

Oct 28, 2024 · Conclusion The PV cell manufacturing process is a complex and precise endeavor that transforms raw materials into high-efficiency solar cells.

Get Started

How are solar panels made?

Aug 17, 2025 · Step Four – Cells laminated to glass Solar cell lamination is a crucial step in the solar panel manufacturing process. After all, the solar panel

Get Started

Dynamic Cutting For Pv Glass | British Glass

The handling and processing of glass are important process steps for the photovoltaic industry, where it can learn and profit from tried and trusted applications from the glass industry. In this

Get Started

Production process and classification of

Nov 15, 2021 · It is made by using a special embossing roller to press a special pyramid pattern on the surface of the ultra-white glass, as shown in Figure 1.

Get Started

6 FAQs about [Photovoltaic glass processing steps]

What is the production process of Photovoltaic Glass?

Production process of photovoltaic glass The deep processing process of photovoltaic glass involves two steps: tempering and coating. The original sheet is ground and then tempered to obtain tempered sheets, or tempered and coated to obtain coated sheets for component packaging.

What raw materials are used in Photovoltaic Glass production?

The raw materials used in the production of photovoltaic glass raw materials include soda ash, quartz sand, feldspar, dolomite, limestone, mirabilite, etc. Quartz sand and soda ash are not only the main components in material input, but also the two types of raw materials that have a significant impact on material costs.

How are photovoltaic absorbers made?

The manufacturing typically starts with float glass coated with a transparent conductive layer, onto which the photovoltaic absorber material is deposited in a process called close-spaced sublimation. Laser scribing is used to pattern cell strips and to form an interconnect pathway between adjacent cells.

What is glass deep processing?

In order to control costs, glass deep processing often uses both glass tempering and film heat treatment simultaneously. In the production process of photovoltaic glass, the cellar furnace is the core production equipment and also a large investment equipment.

What is Photovoltaic Glass?

At present, the mainstream product of photovoltaic glass is low-iron tempered patterned glass (also known as tempered suede glass) with a thickness of 3.2mm or 4mm.

How do solar panels work?

After installing solar cells on the edge of the glass, a mixed coating is applied to the surface of the glass. The coating absorbs sunlight and transmits it to the solar cells installed on the edge of the glass at different wavelengths.

Related Articles

-

Abu Dhabi photovoltaic glass processing manufacturer

Abu Dhabi photovoltaic glass processing manufacturer

-

Photovoltaic glass factory surrounding processing plants

Photovoltaic glass factory surrounding processing plants

-

Photovoltaic glass pressing processing

Photovoltaic glass pressing processing

-

Photovoltaic glass surface

Photovoltaic glass surface

-

Cadmium telluride power generation glass for photovoltaic

Cadmium telluride power generation glass for photovoltaic

-

Photovoltaic glass sun room in Zurich Switzerland

Photovoltaic glass sun room in Zurich Switzerland

-

Is photovoltaic glass a high-energy project

Is photovoltaic glass a high-energy project

-

Democratic Republic of Congo double glass photovoltaic module type

Democratic Republic of Congo double glass photovoltaic module type

-

Tirana Photovoltaic Glass Type Enterprises

Tirana Photovoltaic Glass Type Enterprises

-

New photovoltaic glass manufacturer in Valletta

New photovoltaic glass manufacturer in Valletta

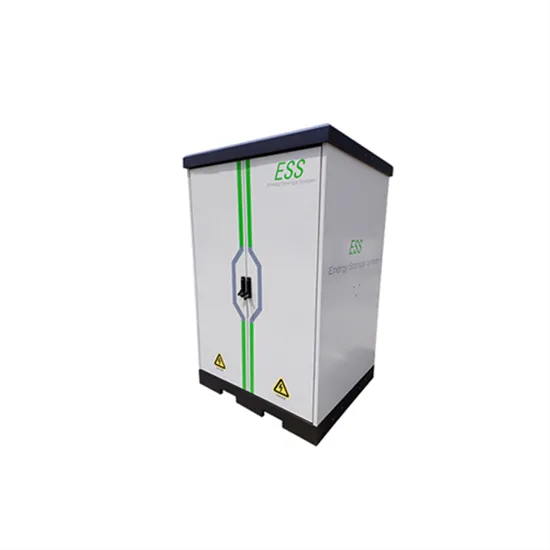

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

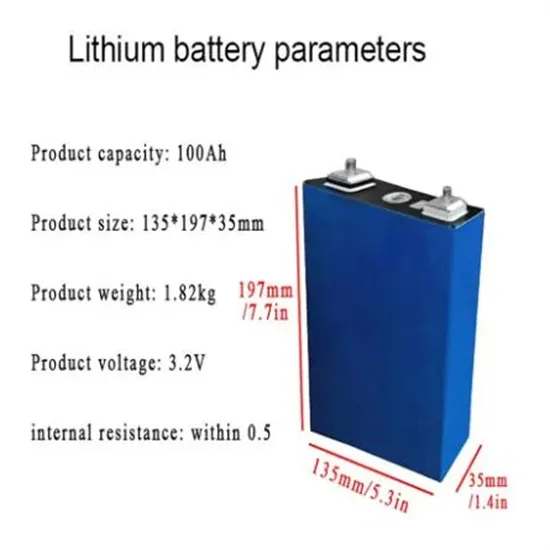

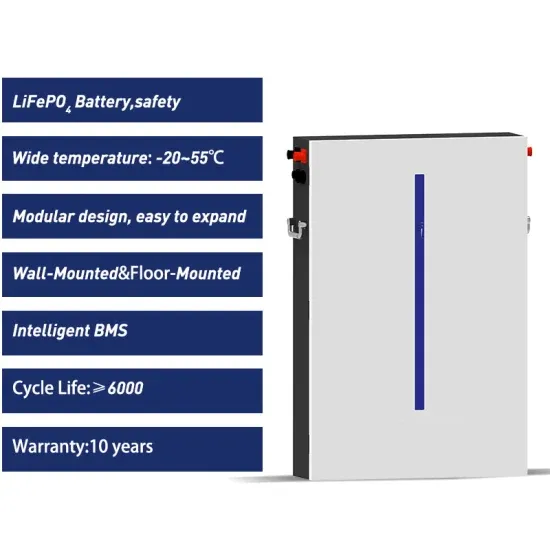

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.