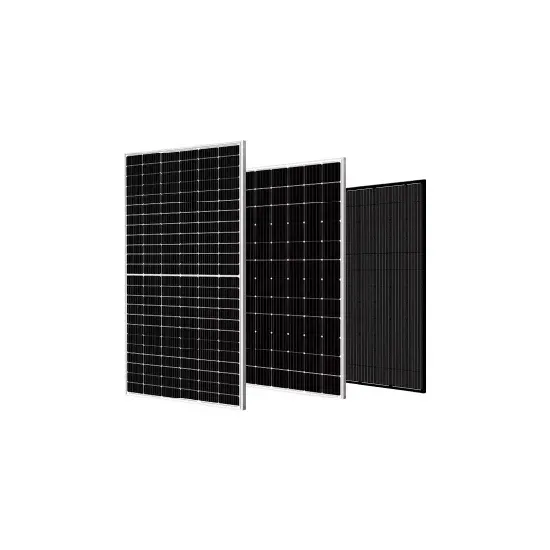

Solar PV module technologies

Jan 1, 2020 · In addition, a few novel solar PV modules have emerged recently, including flexible modules, bifacial modules, double glass modules, antireflection coated glass, light-capturing

Get Started

Assessment of long term reliability of photovoltaic glass–glass modules

Apr 1, 2015 · Quantifying the reliability of photovoltaic (PV) modules is essential for consistent electrical performance and achieving long operational lifetimes.

Get Started

Evo6N N-Type TOPCon Bifacial Double Glass 685-710W

Jul 12, 2024 · ZERO LID (Light Induced Degradation) N-type solar cell has no LID naturally which can increase power generation.

Get Started

Residential Products List | HUAWEI Smart PV

Residential Products List covers all household photovoltaic products, including inverters, energy storage, optimizers, controllers and other household

Get Started

Global perspectives on advancing photovoltaic system

Jan 1, 2025 · Another experimental study analysed the four cooling methods on polycrystalline silicon PV modules to improve efficiency under Egyptian climate. The methods were: forced air

Get Started

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

Get Started

What are the advantages of double-glass photovoltaic modules?

Oct 24, 2024 · High conversion efficiency Double-glass photovoltaic modules use high-efficiency solar cells as photoelectric conversion devices, so they generate more electricity per unit area,

Get Started

Structural diagram of monocrystalline silicon

Download scientific diagram | Structural diagram of monocrystalline silicon double glass photovoltaic panel. EVA: ethylene-vinylacetate. from publication:

Get Started

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · This study will be useful for future PV LCA practitioners as it comprehensively addresses the potential environmental impact of single-crystalline silicon glass-glass modules

Get Started

The research progress on recycling and resource utilization

Jun 15, 2024 · Proposes PV subsidy policies and dynamic standard adjustments. The exponential growth in global photovoltaic installations has led to a continuous increase in photovoltaic (PV)

Get Started

Progress in Separation Technology for Retired Photovoltaic Modules

Jan 1, 2025 · With the "double carbon" target and energy structure upgrading, the PV industry in China is increasing rapidly, and retired PV modules are becoming one of the key limiting

Get Started

Photovoltaic module

Monocrystalline and polycrystalline The most common types of photovoltaic module are monocrystalline silicon, polycrystalline silicon and thin film. Monocrystalline silicon: These dark

Get Started

Modelling Investigation of the Heat Transfer in a Polycrystalline

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views

Get Started

Silicon Solar Cell

Silicon is also useful in manufacturing solar PV technologies, such as mono-crystalline and poly-crystalline silicon PVs. Silicon has been proven to have field stability; hence, crystalline silicon

Get Started

Comparison of Monocrystalline and Polycrystalline Solar Modules

Jun 14, 2020 · As the typical representative of clean energy, solar energy generating systems has the characteristics of long development history, low manufacturing cost and high efficiency,

Get Started

Heat transfer modeling and temperature experiments of

Apr 1, 2017 · The temperature uniform and heat dispersion of modules were compared. In this study, the time-dependent thermal performance of crystalline silicon photovoltaic (PV)

Get Started

How to Select the Best Polycrystalline Photovoltaic Panels

Second look material purity control. Polycrystalline silicon oxygen-carbon ratio exceed 1.4, three years later decay rate directly double. Our testing equipment always carry portable EL tester,

Get Started

The Sun''s Gift: Exploring the World of Photovoltaic Cells | HUAWEI

May 27, 2024 · Dive into the world of photovoltaic cells: their various types, workings, efficiency, benefits, and applications. Empower your knowledge today!

Get Started

How to Select the Best Polycrystalline Photovoltaic Panels

Choose poly panels with ≤0.15mm silicon cutting loss and oxygen-carbon ratio <1.0. Verify 17.5-19.2% STC efficiency using IV testers showing <2% deviation. Select 1.6mm anodized frames

Get Started

(PDF) Silicones for Photovoltaic Encapsulation

Jan 1, 2008 · The encapsulant polymer-based materials in PV-modules must provide proven mechanical stability, electrical safety and protection of the cells

Get Started

Crystalline Silicon Photovoltaic Modules,

Crystalline Photovolataic Glass Crystalline photovoltaic glass refers to solar glass that incorporates traditional crystalline silicon photovoltaic (PV) technology.

Get Started

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules) and the fast pace of

Get Started

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The growing solar photovoltaic (PV) installations have raised concerns about the life cycle carbon impact of PV manufacturing. While silicon PV modules share a similar framed

Get Started

What is the difference between a double-sided double-glass

May 22, 2025 · The production of N-type monocrystalline cells has higher requirements for silicon purity, doping process, cleaning and texturing, and the production cost is higher than that of P

Get Started

Crystalline and Polycrystalline Silicon PV Technology

Feb 24, 2011 · Crystalline and Polycrystalline Silicon PV Technology Crystalline silicon PV cells are used in the largest quantity of all types of panels on the market, representing about 90% of

Get Started

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance product is favored by many PV

Get Started

A comparative life-cycle assessment of photovoltaic

Jan 1, 2018 · Finally, our study also demonstrates that long-term PV module reliability has great impacts on the environmental performance of PV technologies. The environmental benefits (in

Get Started

Double-glass PV modules with silicone encapsulation

Double-glass PV modules with silicone encapsulation 喜欢 0 阅读量: 56 作者: Shencun, Wang, Nick, Shephard, Guy, Beaucarne, Yujian, Wu, Yanxia, Huang

Get Started

Polycrystalline silicon photovoltaic module,

Find your polycrystalline silicon photovoltaic module easily amongst the 51 products from the leading brands (, Bosch, Akcome,) on DirectIndustry, the

Get Started

Chinese PV Industry Brief: Huawei launches new

Jun 8, 2021 · Shenzhen-listed adhesives and chemicals supplier Huitian New Material on Friday announced a plan to invest RMB20 million into new

Get Started

Solar Cells and Modules

Polycrystalline Silicon Photovoltaic (PV) Cells Polycrystalline or multi crystalline silicon PV cells are made from cast square ingots — large blocks of molten

Get Started

Environmental impact assessment of the manufacture and

Sep 10, 2024 · Subsequently, we performed a life cycle assessment of Chinese silicon N-type- and P-type PV modules. The research system encompassed the production processes for

Get Started

6 FAQs about [Huawei polycrystalline silicon double glass photovoltaic modules]

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

Are early PV modules encapsulated with silicone?

Photovoltaics International Early PV modules were often encapsulated with silicone, and have demonstrated outstanding stability in the field, with degradation rates over 20 to 30 years that are much lower than the typical degradation rates for EVA-encapsulated modules [3–5].

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

Is there a new LCI for crystalline silicon PV systems?

In late 2020, IEA PVPS released an updated LCI for PV systems that contains updates for crystalline silicon PV technology reflecting the year 2018, while some information, such as the amounts of auxiliary materials, are still based on 2011 .

What encapsulant materials can be used for PV modules?

Various encapsulant materials can be considered. Polyvinyl butyral (PVB) has been used for a long time for glass–glass PV modules, particularly for thin-film modules.

What is Huawei Smart Module Controller?

The Huawei Smart Module Controller brings you a reassuringly ultimate safeguard. In any emergency, the inverter will be switched off instantly, or for any power outage, the rapid shutdown (RSD) of the module voltage will be activated to clear potential risks on a high-voltage rooftop for personnel and firefighting safety. High Maintenance?

Related Articles

-

Polycrystalline double glass 330w solar photovoltaic panel

Polycrystalline double glass 330w solar photovoltaic panel

-

Double glass polycrystalline photovoltaic panels

Double glass polycrystalline photovoltaic panels

-

Botswana double glass photovoltaic modules

Botswana double glass photovoltaic modules

-

Advantages of Monocrystalline Double Glass Modules

Advantages of Monocrystalline Double Glass Modules

-

Huawei photovoltaic glass consumables

Huawei photovoltaic glass consumables

-

Huawei photovoltaic glass equipment

Huawei photovoltaic glass equipment

-

Is it difficult for Huawei to produce photovoltaic glass in Bolivia

Is it difficult for Huawei to produce photovoltaic glass in Bolivia

-

Tskhinvali double glass photovoltaic module wholesaler

Tskhinvali double glass photovoltaic module wholesaler

-

Pvb double glass photovoltaic module project

Pvb double glass photovoltaic module project

-

Huawei Photovoltaic Solar Modules

Huawei Photovoltaic Solar Modules

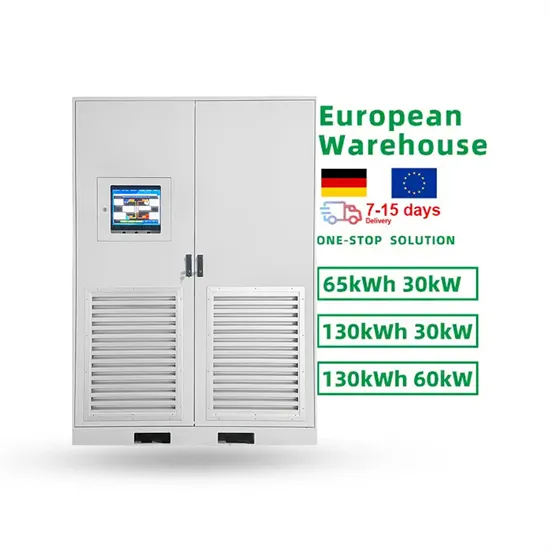

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.