How to Do a Battery Discharge Test

Mar 13, 2025 · A battery discharge test helps evaluate a battery''s performance and health by measuring its voltage and capacity under controlled discharge conditions. Using a Battery

Get Started

Base station battery discharge test method

Battery discharge testing, also known as battery load testing, is a process that test battery health statement by constant current discharging of the set value by continuously

Get Started

Battery Discharge Test System: Working Principle and

Dec 9, 2024 · By simulating real-world discharge scenarios, it helps assess the battery''s capacity, efficiency, and overall health. Regular use of this system ensures that batteries meet their

Get Started

Base station battery charging and discharging test

What is a battery discharge test? Among all the tests, the discharge test (also known as load test or capacity test) is the only test that can accurately measure the true capacity of a battery

Get Started

Q&A: Battery testing

Feb 17, 2025 · Q: Does discharge testing reduce the life of a battery? I''ve heard it called ''destructive testing'' as weaker cells may fail during the test. Is this correct? A: Discharge

Get Started

OPTIMIZATION OF COMMUNICATION BASE STATION BATTERY

Base station battery discharge test method How to proceed the discharge test ?Gather the necessary equipment: You will need a battery or group of batteries, a discharge load, and a

Get Started

FST-CDT48V-300A Battery Charge & Discharge

FST-CDT Battery charge/discharge tester is integrated with constant current discharging, cell voltage collection and intellectualized charging, it provides

Get Started

Base station lead-acid battery charge and discharge times

REVOV''''s lithium iron phosphate (LiFePO 4) batteries are ideal telecom base station batteries.. These batteries offer reliable, cost-effective backup power for communication networks.. They

Get Started

Battery Discharge Testing: Implementing NERC

Jan 10, 2023 · Abstract Periodic testing and maintenance of battery banks is imperative to ensure reliable delivery of power when they are called upon. There are a number of different tests like:

Get Started

Base station battery pack current test

Base station battery pack current test I have a Jackery 1500 Explorer. Under no load (I''''ve not measured under a load) I was seeing 13.3V output. For my higher power radio (KG-1000G) I

Get Started

Main Causes of Shortened Battery Lifespan in Base Stations

Traditional maintenance methods, such as periodic discharge testing, have limitations due to personnel constraints, remote locations, and long testing times. Battery monitoring systems

Get Started

Communication Base Station Battery test Load 48v50A Capacity test

Battery Pack, Battery Cell, detect battery, test battery capacity Charge/Discharge Voltage 220V Brand Name FORESISGHT Model Number FST-CT48V/50A Type battery capacity tester,

Get Started

Base station battery charging and discharging test

What is a battery charge-discharge procedure? The research method used is a (new) battery charge-discharge procedure. Parameters are analyzed by determining the on-site battery

Get Started

How to Charge and Discharge Battery Test Equipment

Aug 14, 2023 · A battery test system (BTS) offers high voltage and current control accuracy to charge and discharge a battery. It is mainly used in manufacturing during production of the

Get Started

Base station battery discharge test method

Base station battery discharge test method What is battery discharge testing? Battery discharge testing,also known as battery load testing,is a process that test battery health statementby

Get Started

Maintenance Points for Telecom Base Station Batteries

① A verification discharge test should be done every year, discharging 30% to 40% of the rated capacity. ②It is recommended to do a capacity test every 3 years ③ During battery discharge,

Get Started

Battery Discharge Testing: A Comprehensive

Jul 1, 2024 · Battery discharge testing, also known as battery load testing, is a process that test battery health statement by constant current discharging of

Get Started

(PDF) Performance Analysis of VRLA Battery for

Oct 22, 2021 · This has shortened the battery life at the Base Station (BTS). This study aims to analyze the performance of a (new) VRLA battery against a DC

Get Started

Quick Guide to Discharge Testing

Nov 1, 2021 · Figure 1 shows a typical battery discharge curve. The capacity test can be done in various ways: constant current discharge, constant power

Get Started

Performance Analysis of VRLA Battery for DC Load at

Mar 5, 2022 · Performance Analysis of VRLA Battery for DC Load at Telecommunication Base Station Imelda Uli Vistalina Simanjuntak1*), Heryanto2), Yossy Rahmawaty3), and Tulus

Get Started

Performance Analysis of VRLA Battery for DC Load at

This has shortened the battery life at the Base Station (BTS). This study aims to analyze the performance of a (new) VRLA battery against a DC load (BTS) to support the continuity of BTS

Get Started

Maintenance Points for Telecom Base Station Batteries

(8) Battery capacity testing and discharge testing should be performed regularly. ① A verification discharge test should be done every year, discharging 30% to 40% of the rated capacity. ②It

Get Started

Battery Cycling Test with Usage Pattern-Based

Battery cycling tests are essential procedures that assess the capacity, efficiency, and overall health of batteries through repeated charge and discharge cycles.

Get Started

Battery Discharge Test System: Working Principle and

Dec 9, 2024 · A Battery Discharge Test System is a vital tool in understanding and managing battery performance. By simulating real-world discharge scenarios, it helps assess the

Get Started

Battery Discharge Testing: A Comprehensive Guide to

Jul 1, 2024 · Battery discharge testing, also known as battery load testing, is a process that test battery health statement by constant current discharging of the set value by continuously the

Get Started

Battery Discharge Testing: Implementing NERC

Jan 10, 2023 · There are a number of different tests like: visual inspections, specific gravity, float voltage and current measurements, discharge test, individual cell condition, inter-cell

Get Started

Base station battery discharge test method

How to proceed the discharge test ?Gather the necessary equipment: You will need a battery or group of batteries, a discharge load, and a way to measure the voltage and current of the

Get Started

Telecom Base Station Backup Power Solution:

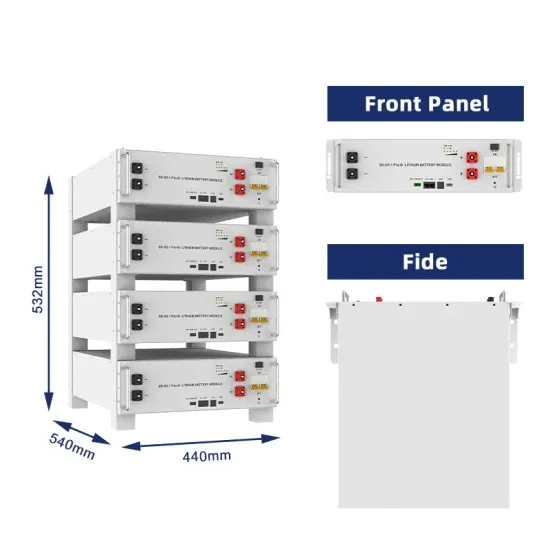

Jun 5, 2025 · Discover the 48V 100Ah LiFePO4 battery pack for telecom base stations: safe, long-lasting, and eco-friendly. Optimize reliability with our

Get Started

6 FAQs about [Base station battery discharge test current]

What is battery discharge testing?

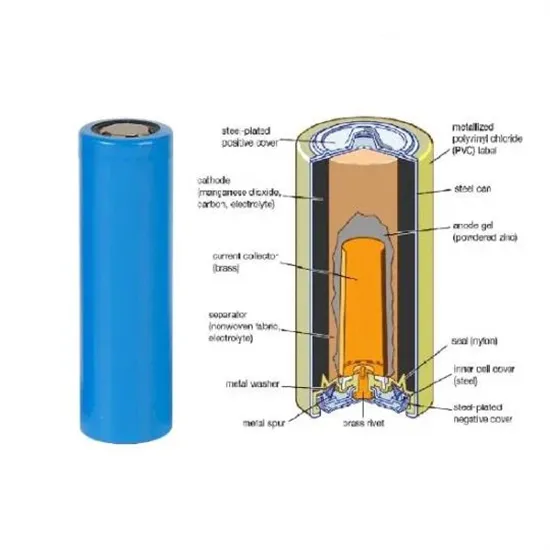

What is battery discharge testing ? Battery discharge testing, also known as battery load testing, is a process that test battery health statement by constant current discharging of the set value by continuously the discharge current from a fully charged state and then measuring how long the battery lasts.

How to test a battery bank?

There are a number of different tests like: visual inspections, specific gravity, float voltage and current measurements, discharge test, individual cell condition, inter-cell resistance, and others, which are recommended in IEEE, NERC and other standards for diagnosing the condition of the battery banks.

What is a battery capacity test?

Although many tests can be performed to assess the condition of the batteries such as ohmic testing, specific gravity, state of charge etc., only the capacity test, commonly referred to as the discharge or load test, can measure the true capacity of the battery system and in turn determine the state of heath of the batteries.

What is a battery testing system?

Its applications include: Battery Health Assessment: Regular testing ensures that batteries continue to perform optimally throughout their lifespan. Quality Control: Manufacturers use this system to test battery samples before they are shipped to customers, ensuring that only high-quality products are sold.

How does a battery test work?

Once the discharge reaches the predetermined cutoff voltage, the system stops the test. The data collected during the test is then analyzed to determine key metrics like the battery's capacity (Ah), efficiency, and overall health. A battery that discharges steadily and reaches its rated capacity typically indicates that it is in good condition.

What parameters are set before a battery test?

Before initiating the test, specific parameters are set, such as the desired discharge rate (usually in amps), the duration of the test, and the cutoff voltage (the point at which the battery should no longer be discharged). These settings are based on the battery’s specifications and intended application. Controlled Discharge

Related Articles

-

BMS current limiting charging of lithium battery in communication base station

BMS current limiting charging of lithium battery in communication base station

-

5g communication base station battery test self-operated

5g communication base station battery test self-operated

-

Base station lithium battery test

Base station lithium battery test

-

Communication base station battery construction power generation specifications

Communication base station battery construction power generation specifications

-

Tajikistan communication base station lead-acid battery maintenance project

Tajikistan communication base station lead-acid battery maintenance project

-

Outdoor lithium battery station cabinet design base station

Outdoor lithium battery station cabinet design base station

-

Base station lead-acid battery capacity

Base station lead-acid battery capacity

-

New Zealand HJ communication base station lithium ion battery

New Zealand HJ communication base station lithium ion battery

-

5G mobile base station equipment electromagnetic battery environment monitoring method

5G mobile base station equipment electromagnetic battery environment monitoring method

-

HJ Is battery communication small base station useful

HJ Is battery communication small base station useful

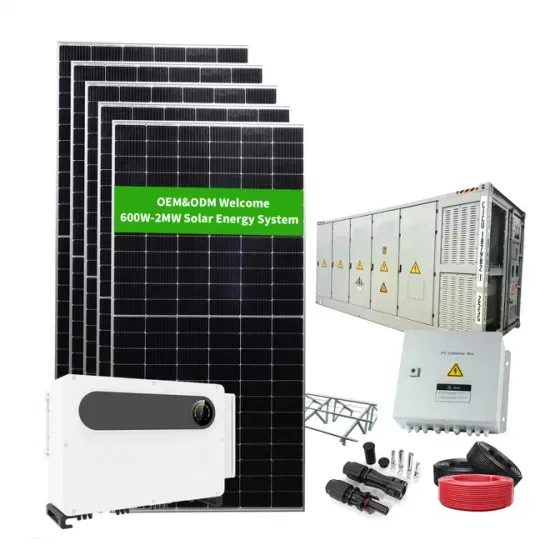

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.