Choosing the Right Lithium Ion Battery Cabinet:

May 1, 2025 · Ensure maximum safety and efficiency with this in-depth guide on selecting a lithium ion battery cabinet. Learn key features, regulations, and

Get Started

Stages of Commissioning: A Detailed Overview

Jul 27, 2024 · The commissioning process is a structured approach that ensures the successful start-up and operation of complex systems. Each of the nine

Get Started

EES Station Commissioning: Procedures & Safety

Oct 22, 2024 · Learn about the integral process of commissioning electrochemical energy storage stations, including procedures, safety measures, and

Get Started

The BESS System: Construction, Commissioning, and O&M

3 days ago · During the commissioning of an energy storage system, which tests does the team perform? How often should we conduct regular inspection tours for an energy storage power

Get Started

Utility-scale battery energy storage system (BESS)

Mar 21, 2024 · Introduction Reference Architecture for utility-scale battery energy storage system (BESS) This documentation provides a Reference Architecture for power distribution and

Get Started

PRODUCTION PROCESS OF A LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode

Get Started

The Ultimate Energy Storage Commissioning Guide: From

Whether you''re handling a 20MW grid-scale beast or a commercial building''s backup power solution, this guide''s got your back. Designed for project engineers, safety inspectors, and

Get Started

GRID CONNECTED PV SYSTEMS WITH BATTERY ENERGY

May 22, 2023 · The term battery system replaces the term battery to allow for the fact that the battery system could include the energy storage plus other associated components. For

Get Started

What are the recommended testing protocols to include in

CPDI, Llithium-ion, UPS, Battery SystemWith the absence of a standardized commissioning test for lithium batteries, we expect that commissioning would be somewhat similar to that of

Get Started

A road map for battery energy storage system

Jun 9, 2025 · Grid-scale battery energy storage system (BESS) installations have advanced significantly, incorporating technological improvements and design

Get Started

The significance of lithium battery energy storage

The commissioning on 1 December 2017 of the Tesla-Neoen 100 MW lithium-ion grid support battery at Neoen''''s Hornsdale wind farm in South Australia, at the time the world''''s largest, has

Get Started

Proper Commissioning Procedures for Lead-Acid Batteries

Jan 10, 2023 · Introduction Throughout my nearly thirty years in the stationary battery industry, I have been told of and witnessed many interesting things relating to the perceived proper

Get Started

Lithium battery energy storage power station

Lithium-Ion Battery Storage for the Grid--A Review of Stationary Battery Storage System Design Tailored for Applications in Modern Power Grids, 2017. This type of secondary cell is widely

Get Started

Lithium Ion Battery Storage Cabinet | Storage Cabinet Supplier

We are a supplier of high-quality Lithium Ion Battery Storage Cabinet, featuring a powder-coated steel chamber with self-closing, oil-damped doors for safe storage and controlled battery

Get Started

Key stages in lithium-ion battery production | Palamatic Process

An industrial revolution driven by innovation Lithium-ion batteries have become indispensable across a wide range of applications: electric vehicles, renewable energy storage, and

Get Started

Lithium battery energy storage power station

Large-scale battery energy storage system (BESS) can effectively compensate the power fluctuations resulting from the grid connections of wind and PV generations which are random

Get Started

Battery Room Ventilation and Safety

Mar 15, 2023 · BATTERY ROOM VENTILATION AND SAFETY It is common knowledge that lead-acid batteries release hydrogen gas that can be potentially explosive. The battery rooms

Get Started

Battery System Start-Up and Commissioning Procedure

Nov 1, 2023 · Pre-startup and commissioning checks/verification is essential steps in ensuring the proper installation and reliable operation of a battery system. What are the key pre-startup and

Get Started

The Commissioning Process: A Step-by-Step Guide

Jun 15, 2020 · The complete commissioning process: a step-by-step guide of each step, what is required for each step, and how to be successful?

Get Started

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · Developments in different battery chemistries and cell formats play a vital role in the final performance of the batteries found in the market.

Get Started

The Ultimate Energy Storage Commissioning Guide: From

Who Needs This Guide? (Spoiler: Everyone Working With Megawatts) commissioning an energy storage system isn''t exactly a walk in the park. Whether you''re handling a 20MW grid-scale

Get Started

Overview of Battery Energy Storage (BESS) commercial

Sep 9, 2021 · Overview of Battery Energy Storage (BESS) commercial and utility product landscape, applications, and installation and safety best practices Jan Gromadzki Manager,

Get Started

BATTERY ENERGY STORAGE SYSTEMS

Nov 9, 2022 · This document e-book aims to give an overview of the full process to specify, select, manufacture, test, ship and install a Battery Energy Storage System (BESS). The content

Get Started

Lithium Battery Charging & Storage Cabinets

Multifile''s Lithium Battery Charging cabinets are available in both a 20 and 8 station version. The cabinets have been designed with a hot wall insulation

Get Started

2030.2.1-2019

Dec 13, 2019 · Scope: This document provides alternative approaches and practices for design, operation, maintenance, integration, and interoperability, including distributed resources

Get Started

Lithium-ion Battery Cabinets – Storemasta

A battery cabinet is a particular type of storage cabinet that reduces the risks associated with lithium-ion batteries. These innovative cabinets create a safer

Get Started

Battery Energy Storage System (BESS)

3 days ago · It is crucial to have an experienced team to navigate and complete the commissioning process. With a decade of experience, IHI Terrasun can

Get Started

How to calculate battery room hydrogen ventilation

How to calculate hydrogen ventilation requirements for battery rooms.For standby DC power systems or AC UPS systems, battery room ventilation is calculated in accordance to EN 50272

Get Started

6 FAQs about [Lithium battery station cabinet commissioning process]

What happens during energy storage project commissioning?

During energy storage project commissioning, every team involved feels the heat: For the EPC (Engineering Procurement and Construction) team, it’s their final stretch of construction and they’re eager to finish.

What is a pre-startup & commissioning check?

Pre-startup and commissioning checks/verification is essential steps in ensuring the proper installation and reliable operation of a battery system. What are the key pre-startup and commissioning checks for a battery system? Verify that the battery frame is assembled in accordance with the manufacturer’s recommendations.

When should a battery energy storage system be inspected?

Sinovoltaics advice: we suggest having the logistics company come inspect your Battery Energy Storage System at the end of manufacturing, in order for them to get accustomed to the BESS design and anticipate potential roadblocks that could delay the shipping procedure of the Energy Storage System.

How are battery energy storage systems transported?

Given the Battery Energy Storage System’s dimen- sions, BESS are usually transported by sea to their destination country (if trucking is not an option), and then by truck to their destination site. A.Logistics The consequence is that the shipment process can be worrisome.

What chemistry is used in battery energy storage system?

Do a quick research. •Battery cell chemistry:LFP (Lithium iron phos- phate – chemical formula LiFePO4) is the main chemistry used in the Battery Energy Storage System industry due to lower cost and increased safety.

How to install a battery cabinet?

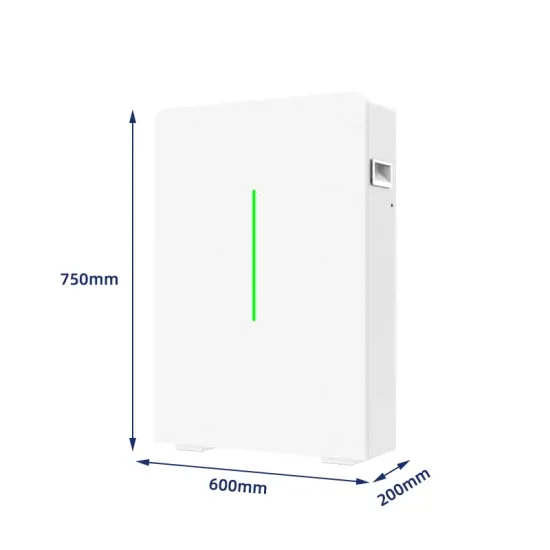

Check the battery cabinet placement against the construction drawing. Ensure there is maintenance space and a distance of more than 0.5 meters from heat sources. Follow the battery installation diagram and manual for installation. Wipe dust off battery terminals and check that each bolt is tightened before installing connection bars.

Related Articles

-

How much does it cost to replace a lithium battery station cabinet in Kuwait City

How much does it cost to replace a lithium battery station cabinet in Kuwait City

-

Lithium iron phosphate battery station cabinet structure

Lithium iron phosphate battery station cabinet structure

-

Equatorial Guinea lithium battery station cabinet customization

Equatorial Guinea lithium battery station cabinet customization

-

Port of Spain lithium battery station cabinet factory direct sales

Port of Spain lithium battery station cabinet factory direct sales

-

Series lithium battery station cabinet

Series lithium battery station cabinet

-

What kind of battery is the lithium battery station cabinet

What kind of battery is the lithium battery station cabinet

-

Lithium battery station cabinet base station energy tooling base station energy

Lithium battery station cabinet base station energy tooling base station energy

-

Lithium battery station cabinet improvement

Lithium battery station cabinet improvement

-

Berlin Communication Base Station Lithium Ion Battery Cabinet Price

Berlin Communication Base Station Lithium Ion Battery Cabinet Price

-

How much is the Tokyo lithium battery station cabinet

How much is the Tokyo lithium battery station cabinet

Commercial & Industrial Solar Storage Market Growth

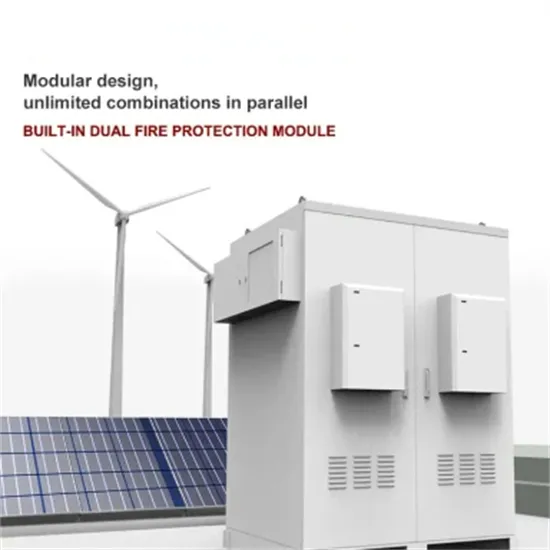

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.