Samsung Gen 2 lithium battery cabinet site plan

Mar 21, 2025 · POWER HOOKUP TO UPS: POSITIVE, NEGATIVE, GROUND. SPECIFICATIONS ARE SUBJECT TO CHANGE. ALL DIMENSIONS ARE IN MILLIMETERS

Get Started

Mitsubishi Electric Power Products, Inc. BC43 Battery

Feb 3, 2025 · Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

Get Started

Galaxy VS UPS for External Batteries Technical

Jan 3, 2025 · Here you can find your UPS installation manual, UPS operation manual, and UPS technical specifications, and you can also find installation manuals for your auxiliary products

Get Started

Grounding for Large UPS Systems

Jun 1, 2002 · Power requirements for data centers and other mission-critical facilities continue to grow. While specific requirements of a facility''s power distribution depend on the nature of its

Get Started

Connecting UPS Grounds and Neutrals | EC&M

Oct 1, 2002 · For multiple battery cabinets incorporating battery disconnects, the cabinets are bolted together, forming a single lineup with the UPS. The

Get Started

2018 Title Contents

Dec 20, 2022 · Abstract Changes in requirements to meet battery room compliance can be a challenge. Local Authorities Having Jurisdictions often have varying requirements based on

Get Started

Eaton UPS fundamentals handbook

Jul 2, 2025 · Handbook. From plug and receptacle charts and facts about power problems to an overview of various UPS topologies and factors affecting battery life, you''ll find a wealth of

Get Started

Technical Specification for Uninterrupted Power

Sep 28, 2022 · In this article, we will learn the technical specification for an uninterrupted power supply (UPS) electrical system used in industries. UPS

Get Started

UPS battery cabinet installation specifications

After the UPS battery cabinet is connected, connect the positive and negative connecting wires of the UPS battery cabinet to the positive and negative terminals of the machine.

Get Started

4400 SERIES BATTERY CABINET

The battery cabinet is equipped with narrow pallet jack or forklift access openings in the front and rear of the cabinet. Move the equipment into the desired location and set in place.

Get Started

UBC80 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Get Started

Overview of Grounding of APC UPS Power Supply Unit (part 2)

Apr 23, 2025 · The APC UPS body, its casing, battery cabinet (rack), etc. need to be connected to the electrical grounding device using grounding wires. Generally speaking, the UPS body does

Get Started

25354

Nov 24, 2016 · The Liebert NX UPS can use a variety of battery types, provided the battery plant is designed for the UPS DC voltage range and the load requirements of your application.

Get Started

UNDERSTANDING UPS SYSTEMS AND BATTERIES

Jul 17, 2024 · On battery cabinets, the disconnect switch should be mounted in the door to allow the battery to be disconnected from the UPS before the door is opened. This best practice is

Get Started

Industrial Outdoor UPS Battery Cabinet, Base Station Cabinet Rainproof

High quality Industrial Outdoor UPS Battery Cabinet, Base Station Cabinet Rainproof Energy Saving from China, China''s leading product market power supply cabinet product, with strict

Get Started

Guidelines for Earthing in UPS installations

Oct 26, 2019 · The frame of the UPS should be connected to the neutral of the UPS and then to a nearby earth electrode in order to create an effective TNS earthing system at the UPS itself for

Get Started

Vertiv™ Liebert® NX UPS For a 225-600kVA Multi

Nov 24, 2016 · The battery shall support the UPS at 100% rated kW load for at least _____ minutes at 77°F (25°C) at startup. The UPS shall have an active power factor-corrected IGBT

Get Started

Galaxy VL | Schneider Electric USA

Schneider Electric USA. Browse our products and documents for Galaxy VL - Highly efficient, scalable 200 to 500 kVA/kW 3-phase UPS featuring modular,

Get Started

Eaton Powerware Intermediate Training

Aug 5, 2010 · There are important considerations regarding the detection of battery ground leakage current, particularly in UPS systems utilizing rack-mounted, flooded electrolyte

Get Started

PRODUCT SPECIFICATION Lithium Ion Battery System

Oct 19, 2020 · The Lithium-Ion chemistry used in the Battery System contains an organic solvent-based electrolyte. If the Battery System is misused, damaged or abused, internal cell pressure

Get Started

25354

Nov 24, 2016 · Battery Cabinets—Valve-regulated, lead-acid (VRLA) sealed batteries are available in matching cabinets for convenient installation and maintenance in otherwise

Get Started

Uninterruptible Power Supply Three-Phase User Manual

Jul 31, 2020 · UPS comes equipped with grounding terminal, in the final installation phase, connect grounding/earthing wire to the external UPS battery cabinets or appropriate grounding

Get Started

-48 VDC Battery Cabinet Installation and User Manual

Apr 21, 2022 · Install the frame ground landing point adapter P/N 556872 to the left or right side of the battery cabinet, as shown in Figure 5. Installing P/N 556872 Frame Ground Landing Point

Get Started

Overview of Grounding for APC UPS Power

Apr 22, 2025 · Almost every electrical design specification mentions the design and installation requirements for grounding, including the design of grounding

Get Started

Eaton 9395 UPS family | Eaton

Apr 1, 2025 · The Eaton 9395 UPS family (consisting of the Eaton 9395XC, Power Xpert 9395P High Performance UPS and the Power Xpert 9395 UPS)

Get Started

Microsoft Word

Nov 15, 2017 · The battery cabinet is equipped with narrow pallet jack or forklift access openings in the front and rear of the cabinet. Move the equipment into the desired location and set in place.

Get Started

Eaton PowerXpert 9395P 300kVA User Manual

Aug 20, 2024 · Battery backup protection can be enhanced by equipping the UPS system with up to four Eaton 9395P battery cabinets containing sealed lead-acid, maintenance-free batteries.

Get Started

U-ENM00044

Feb 3, 2025 · Install the battery cabinet using adjustable leveling legs to ensure the cabinet is level and stable. Ensure the surface supporting the battery cabinet is rated to withstand the

Get Started

Samsung Gen 2 lithium battery cabinet site plan

Mar 21, 2025 · SOURCE 1 (REQUIRED) SHALL BE PROVIDED FROM THE UPS OUTPUT DISTRIBUTION; SOURCE 2 (OPTIONAL) SHALL BE PROVIDED FROM THE UPS BYPASS

Get Started

System earthing arrangements for installations comprising UPSs

4 days ago · When batteries are not installed in a cabinet, i.e. generally in a special room, the measures presented at the end of this chapter should be implemented. Note: The TN system

Get Started

Installation specifications for UPS battery cabinets and

Mar 18, 2025 · Installation specifications for UPS battery cabinets and battery racks. UPS battery cabinet is an intelligent distribution cabinet designed for the energy terminal of data center

Get Started

Eaton BladeUPS maintenance bypass cabinet installation

Aug 25, 2024 · IMPORTANT SAFETY INSTRUCTIONS SAVE THESE INSTRUCTIONS This manual contains important instructions that you should follow during installation and

Get Started

Guidelines for Earthing in UPS installations

Oct 26, 2019 · This neutral point should be bonded to the body of the UPS and connected to its own nearby earth electrode close to the UPS itself. The body earth connections of the UPS

Get Started

6 FAQs about [UPS battery cabinet grounding specifications]

Does my ups need a grounding system?

Without a properly installed grounding system, your UPS won't function correctly. A grounding system allows circuit protection to clear a ground fault, and provides paths for diverting surge current away from the UPS and for removing undesirable currents from the critical load. So what can you do to ensure your grounding system allows your UPS

How does a battery ground fault affect an ups?

The same condition will exist in a UPS system with a (single) battery ground fault. The unit will continue to run, but a battery ground leakage detection monitor will sense the ground current, and then can trigger an alarm on the monitor, and/or through a “building alarm” in the UPS.

What is a grounding point for a UPS system?

Typically, the grounding point is a copper bar mounted on insulators in the electrical room and bonded to the local building steelwork. Whenever you use a delta-connected supply for a UPS system, you must create an artificial neutral. In such cases, a three-resistor network typically provides a logic reference point for the bypass input.

What is the technical specification for an uninterrupted power supply (UPS)?

In this article, we will learn the technical specification for an uninterrupted power supply (UPS) electrical system used in industries. UPS should be designed and constructed in accordance with IEC 62040. All the components should be mounted in an indoor, floor-mounted, metal enclosed panel with enclosure protection IP 42.

Do I need a grounding conduit for a ups rectifier?

UPS rectifier bypass input and output cables must be run in separate conduits. All power cables from DC supply should be sized for a total maximum of 2V drop at maximum discharge current. Control wiring and power wiring must be run in separate conduits. Vertiv recommends installing grounding conductors.

How much does a ups module weigh?

Risk of heavy unit falling over. Improper handling can cause equipment damage, injury or death. Exercise extreme care when handling UPS cabinets to avoid equipment damage or injury to personnel. The UPS module weight is up to 4450lb. (2019kg).

Related Articles

-

UPS battery cabinet lightning protection grounding

UPS battery cabinet lightning protection grounding

-

Ups battery cabinet a32

Ups battery cabinet a32

-

UPS battery cabinet principle

UPS battery cabinet principle

-

Democratic Republic of Congo outdoor UPS battery cabinet

Democratic Republic of Congo outdoor UPS battery cabinet

-

UPS battery cabinet and UPS distribution cabinet

UPS battery cabinet and UPS distribution cabinet

-

Lightning protection grounding for outdoor battery cabinet

Lightning protection grounding for outdoor battery cabinet

-

The function of the grounding wire in the new energy battery cabinet

The function of the grounding wire in the new energy battery cabinet

-

UPS battery cabinet load-bearing frame production

UPS battery cabinet load-bearing frame production

-

Solar power battery cabinet model specifications

Solar power battery cabinet model specifications

-

UPS battery cabinet installation base station

UPS battery cabinet installation base station

Commercial & Industrial Solar Storage Market Growth

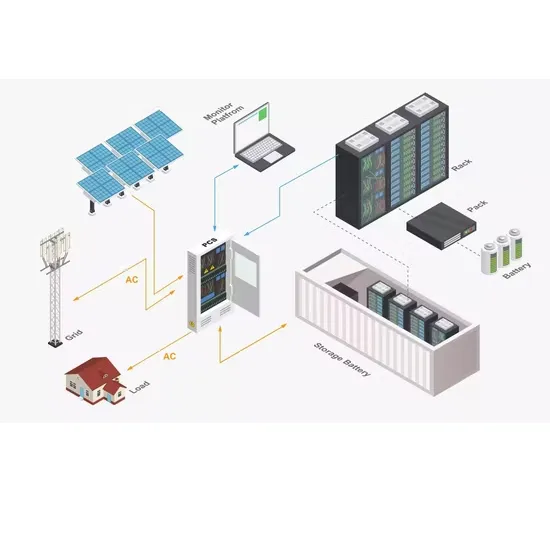

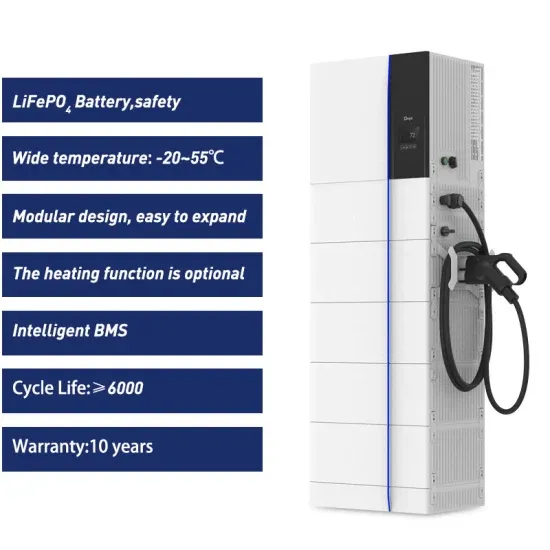

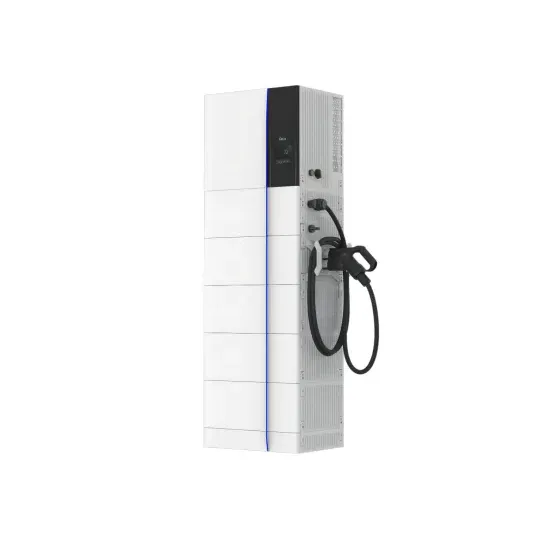

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.