Multicrystalline Silicon

Here, instead of the cells being cut in a pseudo-square shape, they are cut in a square or rectangular shape, thus, making them easier to be packed closely in modules. In terms of

Get Started

Performance of solar photovoltaic modules under arid climatic

Nov 1, 2018 · Photovoltaic panels and concentrated solar thermal power are the most well-established technologies used to convert solar energy into electricity. Using photovoltaic (PV)

Get Started

Life-cycle assessment of multi-crystalline photovoltaic (PV)

Jan 1, 2015 · This study performs a life-cycle assessment for a photovoltaic (PV) system with multi-crystalline silicon (multi-Si) modules in China. It considers th

Get Started

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The growing solar photovoltaic (PV) installations have raised concerns about the life cycle carbon impact of PV manufacturing. While silicon PV modules share a similar framed

Get Started

Top Trends in Solar Module and PV Cell

Feb 5, 2025 · Q3: Will the prices of solar modules continue to fall in 2025? A3: Yes, with new manufacturing processes and increased competition, solar pv

Get Started

Multicrystalline Flexible Photovoltaic Panels: The Future of

That''s exactly what multicrystalline flexible photovoltaic panels bring to the renewable energy table. These thin-film marvels are rewriting the rules of solar installation - you''ll find them

Get Started

PV Modules for Commercial Solar Projects

Aug 17, 2025 · Targray multicrystalline solar modules are ideally suited to meet the evolving needs of today''s photovoltaics industry. Built using the best raw

Get Started

Monocrystalline VS Polycrystalline Solar PV Modules

Jun 20, 2024 · Choosing between Monocrystalline and Polycrystalline PV modules is a huge dilemma. Read this article to quickly compare the cost, efficiency, and lifespan of the two to

Get Started

Moisture induced degradation in field-aged multicrystalline

Aug 15, 2023 · Moisture ingress is one of the key fault mechanisms responsible for photovoltaic (PV) devices degradation. Understanding moisture induced degradation (MID) mechanisms in

Get Started

Multicrystalline Silicon Cell

2.1.2 Polycrystalline silicon (poly-Si) cells Poly-Si cells are also known as the multicrystalline (multi-Si) solar cells. Polycrystalline silicon is a material consisting of multiple small silicon

Get Started

Multicrystalline solar panels module

Go for efficient and robust multicrystalline solar panels module at Alibaba for both residential and commercial uses. Buy amazing multicrystalline solar panels module having mono, poly

Get Started

Defect analysis and performance evaluation of photovoltaic modules

Jan 8, 2025 · Abstract This paper presents a defect analysis and performance evaluation of photovoltaic (PV) modules using quantitative electroluminescence imaging (EL). The study

Get Started

Multicrystalline (Poly) Cell Solar Modules

10Wp to 280Wp- 36 and 72 Cell Solar Modules. Solar cells directly convert sunlight into electricity by means of the photovoltaic effect. This occurs when

Get Started

Life Cycle Assessment of Crystalline Silicon Photovoltaic Module

The objective of this study is to complete a life cycle assessment (LCA) of a novel technology that separates the crystalline silicon (c-Si) photovoltaic (PV) module front glass from the backsheet

Get Started

Multi-crystalline Silicon | UniversityWafer, Inc.

Jan 7, 2025 · Lastly, the long-term stability of a PV module is improved when it is manufactured with a bifacial design. Bifacial modules can increase energy yield by between 10% and 20%.

Get Started

Monocrystalline vs. Polycrystalline solar panels

Jan 9, 2023 · The two main types of silicon solar panels are monocrystalline and polycrystalline. Learn their differences and compare mono vs poly solar.

Get Started

Crystalline Silicon Module

Crystalline silicon (c-Si) modules dominate the PV market with a 95% share [73]. The cells are available in multicrystalline (multi-Si) and mono-crystalline (mono-Si) variants, with mono-Si as

Get Started

Multicrystalline silicon production – PV

2 days ago · Multicrystalline silicon (mc-Si) is silicon material with multiple grains of crystals with different orientation and shape. Mc-Si is often referred to

Get Started

Solar PV Module Price Comparison: Mono vs

5 days ago · Look at Solar PV module prices for monocrystalline, polycrystalline, and thin-film panels. Find out about price variations how well they work, and

Get Started

A method to recycle silicon wafer from end-of-life photovoltaic module

Apr 1, 2017 · A method to recycle silicon wafer from end-of-life photovoltaic module and solar panels by using recycled silicon wafers

Get Started

Israel multicrystalline photovoltaic module panels

What are Targray''s high-efficiency multicrystalline solar modules? Targray''s portfolio of high-efficiency multicrystalline solar modules is built to provide EPCs, installers, contractors and

Get Started

A Complete Guide to PERC Solar Panels (vs.

Mar 6, 2022 · PERC solar panels are more efficient than traditional c-Si panels with reduced heating absorption. How do they compare to other cell techs?

Get Started

Monocrystalline vs Polycrystalline

Aug 12, 2024 · There are two main types of solar panels that dominate the market: monocrystalline panels and polycrystalline (multicrystalline) panels.

Get Started

Monocrystalline Solar Modules for PV Projects

3 days ago · Targray''s extensive portfolio of high-efficiency monocrystalline solar modules is built to provide EPCs, installers, contractors and solar PV

Get Started

Properties of polycrystalline silicon cell

Oct 26, 2018 · Applications of Polycrystalline Silicon 1. Photovoltaic Energy Polycrystalline silicon plays a crucial role in solar energy production,

Get Started

Life cycle assessment of multicrystalline silicon photovoltaic

Aug 1, 2016 · This study aims to identify the environmental effects associated with photovoltaic (PV) cell made up of multicrystalline silicon (multi-Si) in China by life cycle assessment.

Get Started

Life-cycle assessment of multi-crystalline photovoltaic (PV)

Jan 1, 2015 · Areas with higher solar radiation are more suitable for installing PV systems. This study performs a life-cycle assessment for a photovoltaic (PV) system with multi-crystalline

Get Started

Solar Multi-crystalline Module

Multi-crystalline solar modules consist of several PV cells, where each cell has silicon crystals. These crystals allow these cells to serve as semiconductors.

Get Started

Types of PV Panels – Solar Photovoltaic

There are two general types crystalline silicon photovoltaics, monocrystalline and multicrystalline, both of which are wafer-based. Monocrystalline

Get Started

DATA SHEET FOR XL6P36G130 MULTICRYSTALLINE

Jun 10, 2014 · Loading Capacity (40 ft container) : 628 panels in 30 cartons CHARACTERISTICS OF PHOTOVOLTAIC TEMPERATURE DEPENDENCE OF Isc, Voc, Pmax MODULE

Get Started

Life cycle assessment for a grid-connected multi-crystalline

Sep 20, 2021 · The PV system under evaluation was a grid-connected type installed on a rooftop of a building located in CDMX. Twelve integrated modules of a multi-crystalline silicon (mc-Si)

Get Started

Why Monocrystalline Solar Panels Outperform

Feb 25, 2025 · In the rapidly evolving landscape of solar technology, the distinction between monocrystalline and multicrystalline solar cells represents

Get Started

Multicrystalline photovoltaic panel components

Sollatek supplies two photovoltaic (PV) technologies: o Multicrystalline (also called polycrystalline) Made from cells cut from several silicon crystals o Monocrystalline Made from cells cut from

Get Started

Bibliographies: ''Multicrystalline photovoltaic panels'' – Grafiati

Relevant books, articles, theses on the topic ''Multicrystalline photovoltaic panels.'' Scholarly sources with full text pdf download. Related research topic ideas.

Get Started

JinkoSolar''s optimized Eagle MX panels replace

Mar 24, 2017 · JinkoSolar has introduced the Eagle MX solar panel, its next generation smart module for the high-volume mainstream PV panel market

Get Started

6 FAQs about [Multicrystalline photovoltaic module panels]

What is the difference between monocrystalline and multicrystalline solar panels?

There are several differences between monocrystalline and multicrystalline solar panels. The main underlying difference between the two types relates to their cell structure. Monocrystalline panels are made from monocrystalline cells, which consist of a single, pure silicon crystal.

What are Targray's high-efficiency multicrystalline solar modules?

Targray’s portfolio of high-efficiency multicrystalline solar modules is built to provide EPCs, installers, contractors and solar PV developers with reliable, cost-effective material options for their commercial and utility-scale solar energy projects.

How are polycrystalline solar panels made?

Polycrystalline solar cells are produced by fusing different silicon fragments to create the wafers used in solar panel manufacturing. This manufacturing process, while cost-effective, results in slightly lower efficiency compared to monocrystalline panels.

Can you mix polycrystalline and monocrystalline solar panels?

Yes, it is technically possible to mix polycrystalline and monocrystalline solar panels, but several conditions must be met. First, it is best if the two types of panels come from the same manufacturer. Second, the voltage of the panels needs to be the same.

What are the different types of solar PV modules?

Our solar PV modules (mono, mono PERC, multi, bifacial) deliver the high efficiency required by EPCs, solar project developers, installers and contractors.

How efficient are monocrystalline solar panels?

Monocrystalline solar panels are typically 15-25% efficient, surpassing other types like polycrystalline (13-16%) and thin-film (7-18%). This superior efficiency is due to their construction from a single silicon crystal, which allows for more efficient electron movement and higher electricity conversion rates.

Related Articles

-

Huawei multicrystalline flexible photovoltaic panels

Huawei multicrystalline flexible photovoltaic panels

-

Czech multicrystalline photovoltaic module prices

Czech multicrystalline photovoltaic module prices

-

Malaysia single glass photovoltaic module panels

Malaysia single glass photovoltaic module panels

-

Photovoltaic module panels produced in Cordoba Argentina

Photovoltaic module panels produced in Cordoba Argentina

-

Requirements for installing photovoltaic panels in communication base stations

Requirements for installing photovoltaic panels in communication base stations

-

580 Photovoltaic Module Price

580 Photovoltaic Module Price

-

Four major brands of solar photovoltaic panels

Four major brands of solar photovoltaic panels

-

Photovoltaic panels to transform household power supply

Photovoltaic panels to transform household power supply

-

Steel manufacturers for photovoltaic panels

Steel manufacturers for photovoltaic panels

-

Santo Domingo rooftop photovoltaic solar panels

Santo Domingo rooftop photovoltaic solar panels

Commercial & Industrial Solar Storage Market Growth

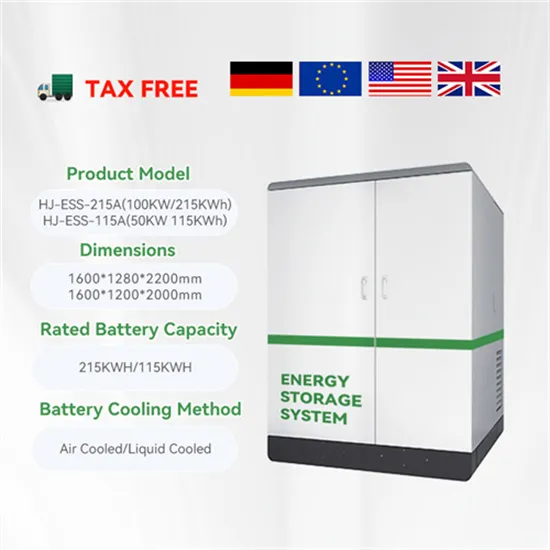

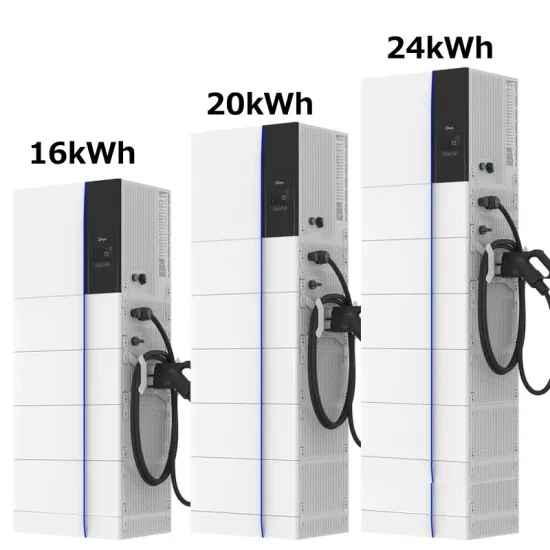

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

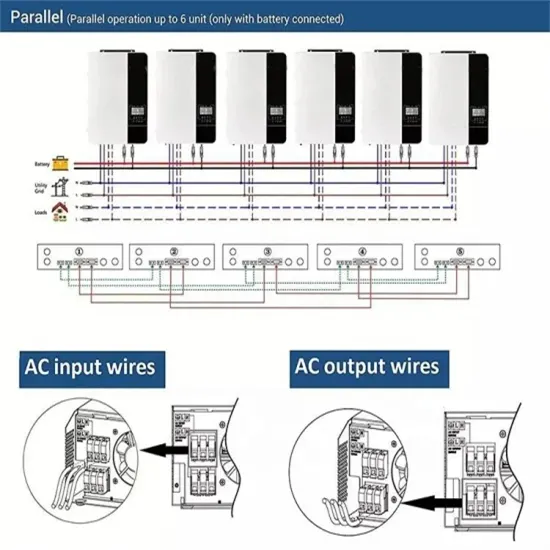

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.