Solar Cell String

The solar cell module is a unit array in the PV generator. It consists of solar cells connected in series to build the driving force and in parallel to supply the required current. A series

Get Started

Rework and repair of components in a solar cell array

A substrate for solar cells is configured such that an area of the substrate remains exposed when at least one solar cell having at least one cropped corner that defines a corner region is

Get Started

PV module quality control and testing: using data and

Nov 24, 2024 · PID is a type of module degradation caused by the high voltage between the PV cells and the glass surface, which is grounded via the substructure of the cell or the frame.

Get Started

PV Moduel Equipment

Oct 9, 2024 · SC Solar has advanced technology in TOPCon, HJT and perovskite cell and module equipment fields, and ranks first in the market share of solar module production line segment.

Get Started

Photovoltaic Manufacturing Outlook in India

Jan 6, 2025 · The CPSU scheme was introduced in 2015 to implement 1GW of grid-connected solar PV power projects using domestic cells and modules, to be set up by

Get Started

Potential measurement techniques for photovoltaic module

Nov 1, 2021 · Cell-cracks (23%) and hotspots (18%) are the most reported sources of PV module defects. The reviewed publications provide strong support for the claims that the I–V curve

Get Started

Failures of Photovoltaic modules and their Detection: A Review

May 1, 2022 · Here, the present paper focuses on module failures, fire risks associated with PV modules, failure detection/measurements, and computer/machine vision or artificial

Get Started

Solar Energy Technician

Aug 18, 2025 · Solar Energy Technicians, also known as Photovoltaic (PV) Installers, play a crucial role in the deployment of solar energy solutions. As the demand for renewable energy

Get Started

Degradation and Failure Modes in New

This detailed analysis by Task 13, provides essential insights into the reliability and performance of cutting-edge photovoltaic technologies, focusing on the

Get Started

PV cells and modules – State of the art, limits and trends

Dec 1, 2020 · Over the past 15 years a categorisation of generations of PV cell and module technology groups has been frequently used. The main features of individual technology

Get Started

Production Process of Photovoltaic Module Manufacturing

Feb 7, 2025 · The module production process generally involves seven steps: string soldering, layout, lamination, framing, junction box installation, curing, and testing, before packaging and

Get Started

APEX 2011_Shangguan_Solar PV

Apr 14, 2025 · Collects input and transfers output current from Module Cells to external cables for interconnection to adjacent Modules and inverters Serial Circuit

Get Started

Production-Rework Operator (Soldering)

Aug 18, 2025 · With innovation, we set the industry standard in the R&D, manufacturing and sales of photovoltaic cells and modules. The world''s leading contractors and developers choose

Get Started

Understanding Photovoltaic Module

Dec 20, 2023 · Abstract Photovoltaic (PV) modules, though reputed for reliability and long lifespans of 25-30 years, commonly experience gradual performance

Get Started

Technical Specification

Mar 30, 2022 · 1 Product overview AM050E MBB PV Cell Soldering Stringer is a fully automatic machine used to solder the mono-Si or poly-Si cells into a string. It can work with 156-230mm

Get Started

Photovoltaic Cell (Polysilicon/ Wafers)

Feb 8, 2024 · Solar cells and modules A photovoltaic (PV) cell, commonly called a solar cell, is a nonmechanical device that converts sunlight directly into electricity. A PV cell is made of

Get Started

Solar Panel Precision: Hot Air BGA Rework Station in Photovoltaic

Seamark, a reputable brand in the electronics industry, has developed an advanced Hot Air BGA Rework Station that is revolutionizing the manufacturing of photovoltaic modules. This cutting

Get Started

Cell & Module Technologies

10 hours ago · Cell and module technologies decide how much energy a PV system delivers, how long it lasts, and how well it pairs with storage. Silicon still dominates, while thin film and

Get Started

Photovoltaic Module: Definition, Importance, Uses and Types

Jul 5, 2024 · A photovoltaic (PV) module is a unit comprised of PV cells that gather sunlight and turn it into energy. Each module contains multiple PV cells shielded by different materials

Get Started

Accelerating Photovoltaic Market Entry with

Nov 20, 2019 · Module replacement can thus accelerate the market introduction and decarbonization impact of emerging PV technologies that have achieved

Get Started

Photovoltaic Failure Fact Sheets 2025

This document, an annex to Task 13''s Degradation and Failure Modes in New Photovoltaic Cell and Module Technologies report, summarises some of the

Get Started

Photovoltaic Automation Knowledge Base

Aug 16, 2025 · The main procedures of the stringer include pulling / cutting PV ribbon, laying, positioning and rectification, soldering and detection, etc. MBB

Get Started

Reasons for rework of photovoltaic cells

The remainder of this review is structured as (also given in Fig. 2): Section 2 gives overview of PV module and its structure, Section 3 provides information about all types of field reported

Get Started

Microsoft Word

May 29, 2015 · There are two soldering process steps used to assemble a PV module; the first step is photovoltaic cell interconnection, called stringing or tabbing, and the second step, PV

Get Started

Solar Panel Repair 101: A Comprehensive Guide

Want to repair your solar panels? Homeowners can repair some damage that can occur, while other damages may require professional help or panel replacement.

Get Started

Analysis of Photovoltaic Module Defects Based on Infrared

Mar 27, 2025 · This study presents a new approach for detecting defects in photovoltaic modules by applying infrared images. It shows a high level of accuracy and efficiency over traditional

Get Started

Tabber and stringer for manufacturing solar

Oct 28, 2016 · By purchasing a solar tabber and stringer, your company will reduce working time and maximise performance of the entire photovoltaic

Get Started

Cell-to-Module Simulation Analysis for

Feb 5, 2022 · A 60-cell photovoltaic (PV) module was analyzed by optimizing the interconnection parameters of the solar cells to enhance the efficiency and

Get Started

Electroluminescence Testing for Optimal PV

Ensure optimal PV module performance with Electroluminescence Testing. Identify micro-cracks and enhance efficiency. Explore our services now!

Get Started

Stringer machines for solar panels

Apr 9, 2025 · Stringer machines for Solar Cells The solar stringer machine is used to solder solar cells together with the use of bus bars into forming strings. This

Get Started

Solar Panel Precision: Hot Air BGA Rework Station in Photovoltaic

May 17, 2025 · These advancements enable manufacturers to efficiently and effectively rework BGA components, ensuring high-quality output and reducing overall production time. In

Get Started

Guidance on PV Module Replacement

Jun 15, 2020 · Throughout a PV system lifetime, it is often necessary to replace modules that are damaged, underperforming, or deemed unsafe to operate. Little industry guidan

Get Started

6 FAQs about [Photovoltaic cell module rework]

What is photovoltaic replacement?

This is the process of replacing damaged, decayed or outdated solar project components, such as Photovoltaic cells (PV). This presents an economically attractive and simple way of keeping models active and efficient. The alternative is replacing the entire system with large wastage and decreasing return on investment.

How to manufacture solar cells?

Put the cells that have the same color and size in different groups. Each group should contain at least 36pcs, 60pcs and 72 pcs of solar cells. Put all the groups in the material tray. Fill the solar pv production process card and stick a barcode on this card. 4.2.2 Technical Requirements in the Solar Cell Manufacturing

How to repair a photovoltaic module?

A repair center specializes in repairing photovoltaic modules. Among other things, it is possible to replace charred junction boxes. The old socket is carefully removed from the module and a new socket is then placed on the back of the module. It is also possible to replace the frames on the modules in the workshop.

How to install a solar cell?

Ensure that the solar cells are in the accordance with the national standard. Turn the solar cell front up and view it from different angles. Put the cells that have the same color and size in different groups. Each group should contain at least 36pcs, 60pcs and 72 pcs of solar cells. Put all the groups in the material tray.

Can solar cells be repaired?

Colloquially, the term "solar cell repair" is often used. Although it is possible to replace individual solar cells in the module, it is not really economical. One therefore always speaks of repairing photovoltaic modules. However, whether this is possible depends on the type of damage.

How to create a solar PV production process card?

Turn the solar cell front up and view it from different angles. Put the cells that have the same color and size in different groups. Each group should contain at least 36pcs, 60pcs and 72 pcs of solar cells. Put all the groups in the material tray. Fill the solar pv production process card and stick a barcode on this card.

Related Articles

-

Dubai Photovoltaic Cell Module

Dubai Photovoltaic Cell Module

-

How many volts does each cell of a 660w photovoltaic module have

How many volts does each cell of a 660w photovoltaic module have

-

Photovoltaic cell module conversion

Photovoltaic cell module conversion

-

Ethiopia photovoltaic cell module manufacturers

Ethiopia photovoltaic cell module manufacturers

-

Photovoltaic cell module factory in southern Spain

Photovoltaic cell module factory in southern Spain

-

Maximum power of photovoltaic cell module

Maximum power of photovoltaic cell module

-

Libreville Photovoltaic Cell Module

Libreville Photovoltaic Cell Module

-

Who are the customers of photovoltaic cell module factories

Who are the customers of photovoltaic cell module factories

-

Photovoltaic cell equipment and component equipment

Photovoltaic cell equipment and component equipment

-

Bishkek Transparent Series Photovoltaic Glass Module Cells

Bishkek Transparent Series Photovoltaic Glass Module Cells

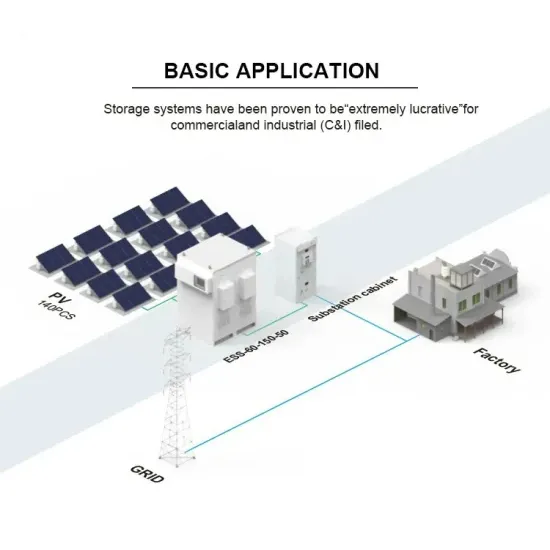

Commercial & Industrial Solar Storage Market Growth

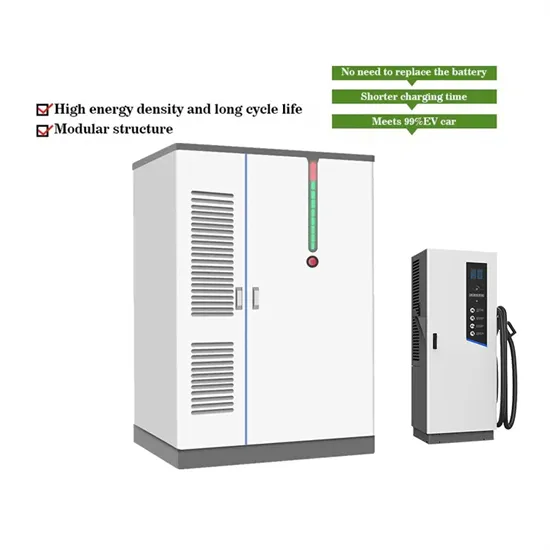

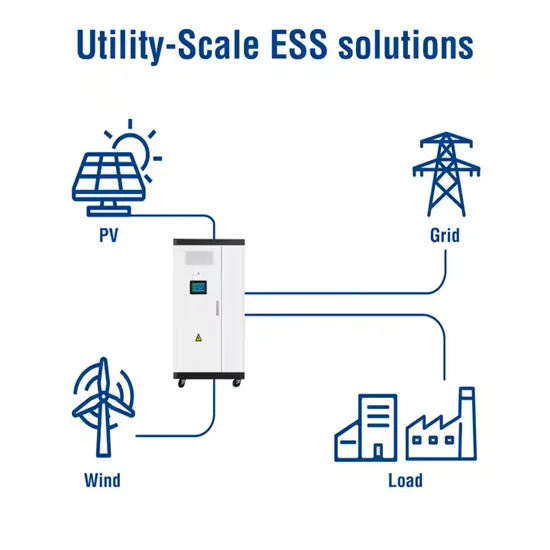

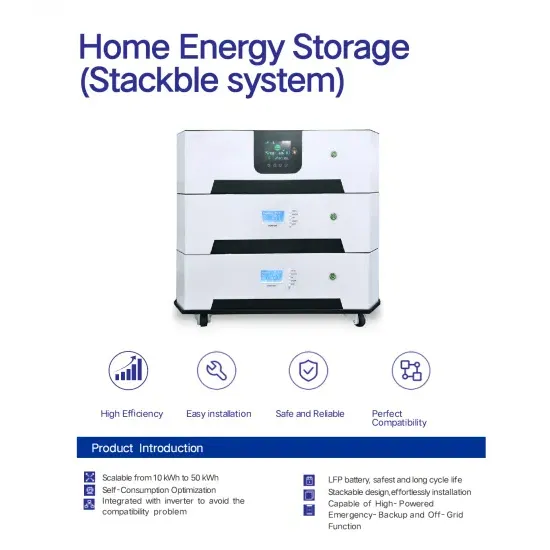

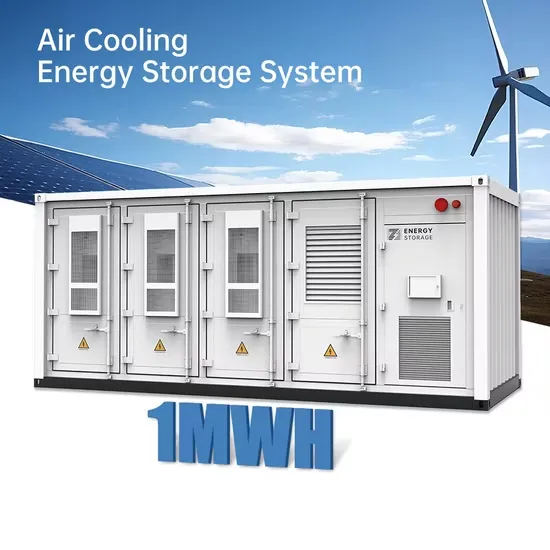

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.