Cost Projections for Utility-Scale Battery Storage: 2023

Jul 25, 2023 · Executive Summary In this work we describe the development of cost and performance projections for utility-scale lithium-ion battery systems, with a focus on 4-hour

Get Started

Lithium Battery Pack | Industrialist Wiki | Fandom

6 days ago · The Lithium Battery Pack is the final stage in Lithium production, which cannot be processed further and can be sold for $85,000. Ten Lithium

Get Started

Breaking Down the Cost of an EV Battery Cell

Feb 22, 2022 · Breaking Down the Cost of an EV Battery Cell As electric vehicle (EV) battery prices keep dropping, the global supply of EVs and demand for

Get Started

Lithium-Ion Battery Production Cost Analysis

Case Study on Lithium-Ion Battery Production Cost: A comprehensive financial model for the plant''s setup, manufacturing, machinery and operations.

Get Started

The Real Cost of Commercial Battery Energy

Apr 21, 2025 · What are the costs of commercial battery storage? Battery pack - typically LFP (Lithium Uranium Phosphate), GSL Energy utilizes new A-grade

Get Started

Lithium-Ion Battery Manufacturing Plant: Setup

The lithium-ion battery manufacturing plant report provides detailed insights into project economics, cost breakdown, setup requirements & ROI etc.

Get Started

Custom 48V lithium battery pack, how much

Jan 20, 2022 · 48V lithium-ion battery definition The single battery on the market is generally around 3.7v, but many times a slightly larger operating voltage

Get Started

Breaking Down the Cost of an EV Battery Cell

Jan 6, 2025 · Inside each EV battery pack are multiple interconnected modules made up of tens to hundreds of rechargeable Li-ion cells. Collectively, these

Get Started

Battery price per kwh 2025| Statista

Jun 21, 2025 · The cost of lithium-ion batteries per kWh decreased by 20 percent between 2023 and 2024. Lithium-ion battery price was about 115 U.S. dollars

Get Started

How Much Does It Cost to Start a Lithium Ion

Mar 29, 2025 · Discover the costs of starting a lithium-ion battery manufacturing business. Our detailed guide helps you budget and plan for a successful launch.

Get Started

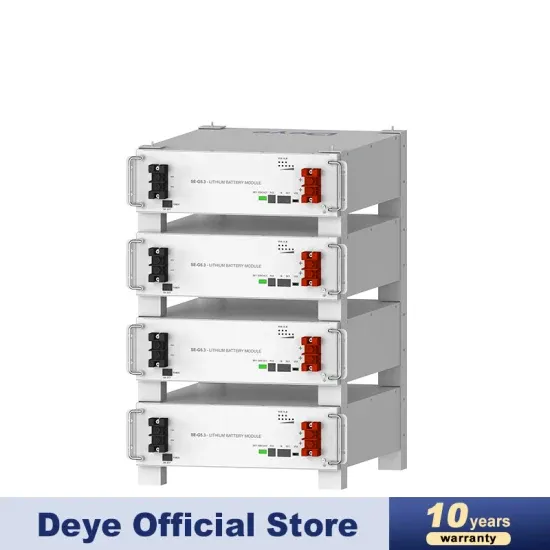

What Determines Rack Battery Cost per kWh in 2025?

Mar 12, 2025 · Rack battery cost per kWh ranges from $150 to $400 in 2024, depending on chemistry, capacity, and supply chain factors. Lithium-ion dominates the market due to higher

Get Started

What Factors Influence Custom Battery Pack Manufacturing

Feb 18, 2025 · Answer: Custom battery pack manufacturing prices depend on cell chemistry, capacity, design complexity, safety certifications, and order volume. Lithium-ion batteries cost

Get Started

Historical and prospective lithium-ion battery cost

Jan 15, 2024 · Lithium-ion batteries (LiBs) are pivotal in the shift towards electric mobility, having seen an 85 % reduction in production costs over the past decade. However, achieving even

Get Started

Tesla New LFP Battery Factory and the Push for

Jul 8, 2025 · By producing lower-cost LFP cells in-house and in the US, Tesla can significantly reduce the cost of its battery packs, which is the key to offering its

Get Started

How To Set Up A Lithium-Ion Battery Manufacturing Plant In

The government shifts its focus to the idea of electric mobility and renewable sources, the prospect of establishing a Lithium-Ion Battery Manufacturing Plant In India.

Get Started

EV Battery Pack Costs Were Cut By 90% From

The two main engines of mass electrification are battery energy density and battery costs and both improved tremendously over the past 15 years.

Get Started

How To Estimate The Costs To Start A Lithium

Apr 17, 2025 · How Much Does It Cost To Start Lithium Ion Battery Manufacturing? Launching a lithium ion battery factory demands rigorous

Get Started

How much CO2 is emitted by manufacturing

Aug 8, 2025 · It depends exactly where and how the battery is made—but when it comes to clean technologies like electric cars and solar power, even the

Get Started

The Battery Cell Factory of the Future | BCG

Jan 30, 2025 · Optimizing cell factories for next-generation technologies and strategically positioning them in an increasingly competitive market is key to

Get Started

How much does a lithium-ion battery cost?

Oct 14, 2024 · The cost of lithium-ion batteries varies, but as of 2023, prices are around $139 per kilowatt-hour for packs. This translates to about $11,120 for an 80 kWh electric vehicle battery

Get Started

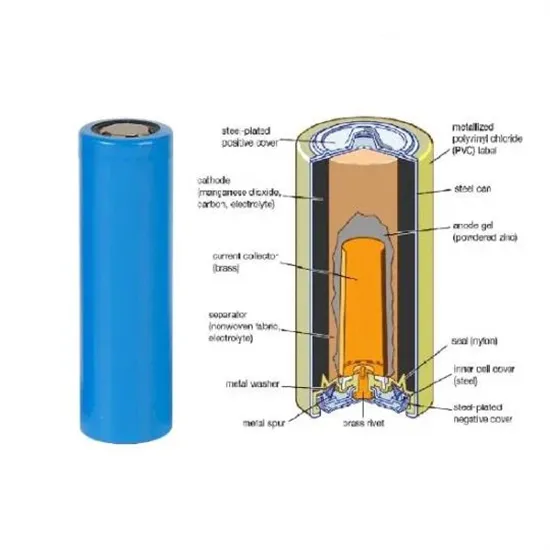

THE COST COMPONENTS OF A LITHIUM ION

Aug 17, 2025 · A lithium-ion battery cell for a smartphone costs the device OEM somewhere between $2 to $4 depending on its capacity and other design

Get Started

Lithium-Ion Battery Pack Prices See Largest Drop

New York, December 10, 2024 – Battery prices saw their biggest annual drop since 2017. Lithium-ion battery pack prices dropped 20% from 2023 to a

Get Started

Battery Pack Certifications – Costs, Timelines and Key

The result: a faster path to market, reduced costs, and total confidence in your product''s compliance. Lithium battery safety is at the top of the list for anyone who manufactures custom

Get Started

What Are the 9 Operating Costs in Electric

Jul 24, 2025 · These layered costs form the complete picture of battery production cost analysis, essential for understanding the comprehensive EV battery

Get Started

Prices of Lithium Batteries: A Comprehensive Analysis

Apr 11, 2025 · Lithium battery prices fluctuate due to raw material costs (e.g., lithium, cobalt), manufacturing innovations, geopolitical factors, and demand surges from EVs and renewable

Get Started

What Are the 2025 Startup Costs for Lithium Ion Battery

Jul 24, 2025 · Advanced Battery Assembly Machines: High-speed equipment for assembling lithium ion batteries can cost between $500,000 and $2 million. Testing Equipment: Ensuring

Get Started

How does the cost of lithium-ion batteries vary

Nov 6, 2024 · China Lowest Prices: China typically offers the lowest lithium-ion battery prices globally. In 2023, average battery pack prices in China were

Get Started

How Much Does Commercial & Industrial Battery Energy Storage Cost

Jul 8, 2024 · Benefits of Investing in Commercial & Industrial Battery Energy Storage Despite the costs, investing in commercial & industrial battery energy storage can offer numerous benefits:

Get Started

What Are the 9 Startup Costs for Battery Manufacturing in

Jul 24, 2025 · How Much Does It Cost To Start Battery Manufacturing For Electric Vehicles? Starting an EV battery manufacturing business, such as VoltCraft Innovations, requires careful

Get Started

Start Lithium Ion Battery Manufacturing: Costs

Apr 6, 2025 · When it comes to constructing a factory for lithium-ion battery production, businesses can expect to spend anywhere from $500,000 to

Get Started

How much does it cost to build a battery energy

How much does it cost to build a battery in 2024? Modo Energy''s industry survey reveals key Capex, O&M, and connection cost benchmarks for BESS projects.

Get Started

Lithium Ion Battery Manufacturing: Cost

Jul 12, 2025 · Ever wondered about the Lithium Ion Battery Manufacturing Cost when launching your battery factory? Do fixed costs, raw material prices, and

Get Started

What Are the 2025 Startup Costs for Lithium Ion Battery

Jul 24, 2025 · Discover the 9 essential startup costs for launching a lithium ion battery manufacturing business. Learn about equipment, materials, and operational expenses.

Get Started

Lithium ion Battery Manufacturing Plant Cost Report

Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an lithium ion battery manufacturing plant. The report

Get Started

Lithium Production Cost Analysis Reports 2025

Procurement Resource provides in-depth cost analysis of Lithium production, including manufacturing process, capital investment, operating costs, and financial expenses.

Get Started

6 FAQs about [How much does a lithium battery pack factory cost]

How much does a lithium ion battery cost?

Lithium ion battery costs range from $40-140/kWh, depending on the chemistry (LFP vs NMC), geography (China vs the West) and cost basis (cash cost, marginal cost and actual pricing). This data-file is a breakdown of lithium ion battery costs, across c15 materials and c20 manufacturing stages, so input assumptions can be stress-tested.

Is lithium ion battery manufacturing a good investment?

This surge presents an incredible opportunity for entrepreneurs looking to dive into the battery manufacturing industry. Lithium Ion Battery Manufacturing Costs can be a significant barrier to entry, but understanding these costs can set you on the right path to success.

How to start a lithium ion battery manufacturing business?

Starting a lithium ion battery manufacturing business requires a comprehensive understanding of the costs involved. From raw materials to labor, each component contributes to the overall manufacturing expenses. It’s essential to evaluate these costs meticulously to ensure profitability and sustainability in the competitive battery market.

How are materials costs of lithium ion batteries calculated?

The breakdown covers 25 categories (e.g., lithium, nickel, graphite), across 10 different battery chemistries (e.g., NCA, NMC, LFP and others, chart below). Materials costs of lithium ion batteries can be calculated by comparing our mass balances above with the costs of different input commodity prices.

What is the lithium-ion battery manufacturing plant project report 2025?

IMARC Group’s report, titled “ Lithium-Ion Battery Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue, ” provides a complete roadmap for setting up a lithium-ion battery manufacturing plant.

What is included in a lithium-ion battery project report?

The lithium-ion battery project report provides detailed insights into project economics, including capital investments, project funding, operating expenses, income and expenditure projections, fixed costs vs. variable costs, direct and indirect costs, expected ROI and net present value (NPV), profit and loss account, financial analysis, etc.

Related Articles

-

How much does a lithium battery pack cost in Kenya

How much does a lithium battery pack cost in Kenya

-

How much does it cost to produce a lithium battery pack

How much does it cost to produce a lithium battery pack

-

How much does a lithium battery pack for energy storage cost

How much does a lithium battery pack for energy storage cost

-

How many amperes are there in a 12v lithium battery pack with 3 series and 8 parallels

How many amperes are there in a 12v lithium battery pack with 3 series and 8 parallels

-

How many volts are needed to charge a 12v lithium battery pack

How many volts are needed to charge a 12v lithium battery pack

-

How much does a lithium battery storage container cost

How much does a lithium battery storage container cost

-

How much is the lithium battery pack in Solomon Islands

How much is the lithium battery pack in Solomon Islands

-

How much does a lithium battery photovoltaic panel cost

How much does a lithium battery photovoltaic panel cost

-

Lithium battery pack factory voltage

Lithium battery pack factory voltage

-

How much is the lithium battery pack in Afghanistan

How much is the lithium battery pack in Afghanistan

Commercial & Industrial Solar Storage Market Growth

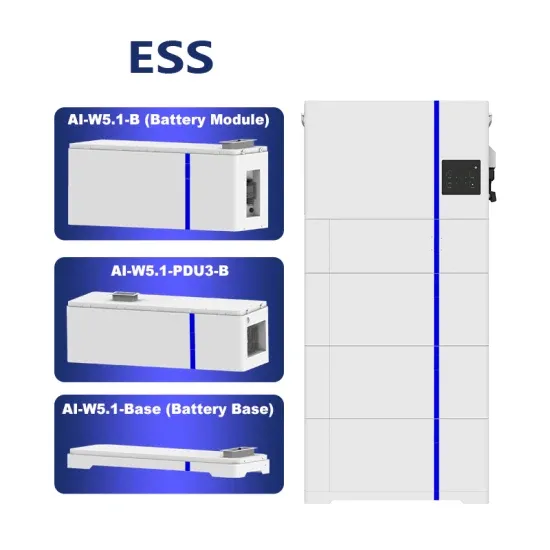

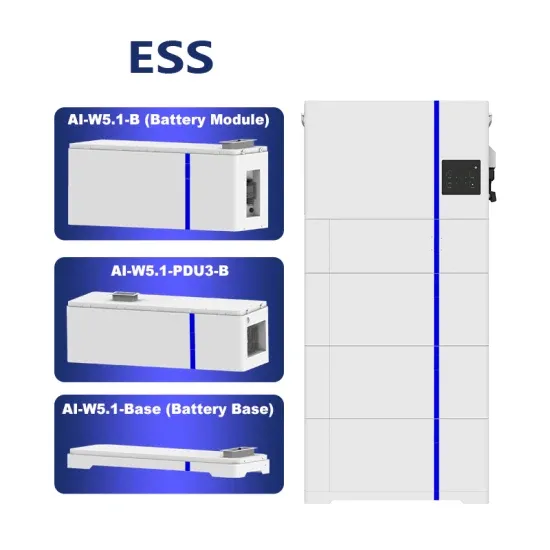

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.