Krannich Solar Germany: Double glass solar panels

Nov 17, 2023 · Double glass solar panels replace traditional polymer backsheets with a glass layer on the back of the module. This design encapsulates the

Get Started

INSTRUCTIONS FOR PREPARATION OF PAPERS

3 days ago · ABSTRACT: Double-glass modules provide a heavy-duty solution for harsh environments with high temperature, high humidity or high UV conditions that usually impact

Get Started

Flexible vs. Rigid Double-Glass Solar Panels:

These panels consist of photovoltaic cells made from silicon wafers arranged together and encased in tempered glass and aluminum frames. As an

Get Started

Error pattern: Glass breakage | SecondSol

Solar modules consist of a front glass and the solar cells, which are embedded between two films, or various semiconductor layers, which are applied to this

Get Started

Presentation

Jun 1, 2023 · Currently, glass-glass modules (~15.2 kg/m2) are about 35-40% heavier per unit area than glass-backsheet modules (~11.3 kg/m2)* Almaden advertises 2mm double glass

Get Started

The Difference Between Bifacial Module and

Sep 4, 2023 · Bifacial solar modules and double glass bifacial solar modules are both types of solar panels designed to capture sunlight from both sides (front

Get Started

What is the difference between a double-sided double-glass

May 22, 2025 · The backplane materials of ordinary modules (such as PET base film) are prone to aging and cracking under the action of ultraviolet rays, humidity, and temperature changes,

Get Started

Bifacial Solar Panels: What are They and Are

Apr 14, 2024 · This stands in contrast to conventional solar panels which have opaque backsheets. These days, many bifacial panel designs incorporate

Get Started

Vertex Double Glass Bifacial 600W+ Module

May 20, 2021 · Introducing The Vertex 600W Bifacial Dual Glass Monocrystalline Module Based on the 210mm large-size silicon wafer and monocrystalline

Get Started

JA Solar PV Bifacial Double-glass Modules Installation

Nov 20, 2024 · This Installation Manual contains essential information for electrical and mechanical installation that you must know before handling and installing JA Solar modules.

Get Started

What are the advantages of dual-glass Dualsun modules?

Aug 18, 2025 · Mechanical constraints on cells: the fact that the structure of the double glass modules is symmetrical implies that the cells are located on a so-called neutral line, the upper

Get Started

Bifacial Photovoltaics 2021: Status, Opportunities

Dec 11, 2020 · The reason for this is that bifacial solar cells are the result of an evolution of crystalline Si PV cell technology and, at the same time, module

Get Started

双玻光伏组件介绍

Oct 31, 2017 · The utility model relates to a double glass photovoltaic component, which is a composite layer composed of two pieces of glass and a solar

Get Started

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · Canadian Solar''s Dymond double glass module passed 3 times IEC standard test and IEC 61730-2:2016 multiple combination of limit test and obtained VDE report, which fully

Get Started

High performance double-glass bifacial PV modules

Oct 5, 2016 · Significant amount of near infrared light passes through bifacial cells. Double-glass structure shows a loss of ~ 1.30% compare to the glass/backsheet structure under STC

Get Started

Double the strengths, double the benefits

Feb 21, 2025 · Traditional solar panels typically feature a glass front and a polymer backsheet. In contrast, double glass modules replace the polymer

Get Started

Trina Solar: Double-Glass

Jun 25, 2019 · In March this year, Trina Solar released its next generation of four module series, including its double-glass module''s updated version, and bifacial double-glass modules, which

Get Started

Glass/glass photovoltaic module reliability and degradation:

Aug 3, 2021 · Abstract Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for

Get Started

Single-glass versus double-glass: a deep dive

Oct 2, 2024 · Left: a double-glass module; right, a bifacial single-glass module. The wave of industrial consolidation is growing ever more pronounced,

Get Started

How does the double-glass design enhance the resistance to

Oct 31, 2024 · By limiting moisture penetration, the double-glass design inhibits this ion migration, thereby lowering PID risk. Symmetrical structure and neutral mechanical stresses: In double

Get Started

Modelling of a double-glass photovoltaic module using finite

Dec 1, 2005 · A simulation model of finite differences describing a double-glass multi-crystalline photovoltaic module has been developed and validated using experimental data from such a

Get Started

INSTRUCTIONS FOR PREPARATION OF PAPERS

Jul 12, 2025 · ABSTRACT: Double-glass modules provide a heavy-duty solution for harsh environments with high temperature, high humidity or high UV conditions that usually impact

Get Started

Multifunctional coatings for solar module glass

Apr 22, 2024 · Currently, single-layer antireflection coated (SLARC) solar glass has a dominant market share of 95% compared to glass with other coatings or

Get Started

What are Double Glass Solar Panels?

Aug 18, 2025 · Some manufacturers, in order to reduce the weight of the modules, have opted for a thickness of 1.6 mm. Dualsun has chosen to stay with a thickness of 2.0 mm for reasons

Get Started

What are the differences between single-glass

Oct 22, 2020 · For Raytech double-glass solar modules, there are two layers of tempered glasses covering on both sides of the solar panel. The benefits of

Get Started

Glass-Glass Modules: The Revolution for Solar Installers –

Dec 18, 2024 · A Look Behind the Robust Technology The biggest difference from traditional glass-film modules lies in the construction: glass-glass modules consist of two durable glass

Get Started

7 Advantages of Bifacial Glass-Backsheet

Aug 23, 2023 · However, approximately 30% of bifacial cells are being used in monofacial modules, i.e. modules with a non-transparent back cover. These

Get Started

Difference between Single-glass and Double

Double-glass or bifacial solar panels consist of two layers of tempered glass covering the front and rear sides of the panel. A layer of encapsulant

Get Started

2025 Complete Guide to Glass-Glass Solar

A comprehensive analysis of the structural principles, performance advantages, and typical application scenarios of glass-glass PV modules, aligned with

Get Started

Solar Glass Durability and Failure Modes —

Sep 18, 2024 · For the 2024 PV Module Index Report, RETC sought to better understand the unique field failure modes associated with ultra-large-format

Get Started

What are the differences between single-glass

Oct 22, 2020 · Single-glass Solar Module: As the first layer of materials in the solar module structure, tempered glass can effectively protect the panel and

Get Started

What is the Double Glass Photovoltaic Solar Panel?

Glass-glass module structures (Dual Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of the traditional

Get Started

Growth Strategies in Double Glass Module Photovoltaic Glass

Jan 17, 2025 · The global double glass module photovoltaic glass market is projected to reach a value of USD 29.5 billion by 2033, exhibiting a CAGR of 11.5% during the forecast period from

Get Started

Bi-facial Double Glass

Feb 22, 2023 · Our innovations are designed and engineered in Singapore. Among our product portfolio is the High-Power Density low-glare module (GMD series), 3-in-1 Building-Integrated

Get Started

A Quantitative Comparison Between Double Glass Photovoltaic Modules

Jul 27, 2017 · We compared the output power of full-size, half-size, and quarter-size cells of a double glass transparent PV module quantitatively, finding cell-to-module values of 96.79%,

Get Started

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Get Started

6 FAQs about [How big is the cell in a double-glass module ]

What is a double glass module?

Double glass module contains two sheets of glass, whereby the back sheet is made of heat strengthened (semi-tempered) glass to substitute the traditional polymer backsheet. With * Corresponding author. Tel.: +86 13776101913; fax: +86 51268961413.

What is the thickness of a glass module?

The thickness of the front glass generally used for this type of structure is 3.2 mm. Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each.

Why are double glass modules symmetrical?

Mechanical constraints on cells: the fact that the structure of the double glass modules is symmetrical implies that the cells are located on a so-called neutral line, the upper part of the module being in compression during a downward mechanical load and the lower glass surface being in tension.

What is double glass photovoltaic module?

Preface To further extend the s rvice life of photovoltaic modules, double glass photovoltaic module has cently been develop d and st died in the PV community. Double lass module contains two sheets of glass, whereby the back sheet is made of heat strengthened (semi-tempered) glass to substitute the traditional polymer backsheet.

What is a dual-glass module?

Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each. Some manufacturers, in order to reduce the weight of the modules, have opted for a thickness of 1.6 mm. DualSun has chosen to stay with a thickness of 2.0 mm for reasons explained below.

Why is white double glass PV module more powerful than transparent?

Due to the high reflectance of white EVA, the power of white double glass module is higher than that of transparent double glass module by 2-4%. Double glass PV modules is an area of significant investigation by many companies and institutes in recent years, for example Dupont, Trina, Apollon, SERIS, MIT, Meyer Burger and Talesun.

Related Articles

-

How big an inverter should I use for a 58kw module

How big an inverter should I use for a 58kw module

-

How many volts does each cell of a 660w photovoltaic module have

How many volts does each cell of a 660w photovoltaic module have

-

How big an inverter should a 30kw photovoltaic power station use

How big an inverter should a 30kw photovoltaic power station use

-

How big a 150w power inverter should I buy

How big a 150w power inverter should I buy

-

How big a battery does the inverter need

How big a battery does the inverter need

-

How big of an inverter is usually used for lithium batteries

How big of an inverter is usually used for lithium batteries

-

How big an inverter is needed for rooftop photovoltaics

How big an inverter is needed for rooftop photovoltaics

-

How big is the generator at St George Power Station

How big is the generator at St George Power Station

-

How big is the photovoltaic panel power of 1 kilowatt

How big is the photovoltaic panel power of 1 kilowatt

-

How to make a base station power module

How to make a base station power module

Commercial & Industrial Solar Storage Market Growth

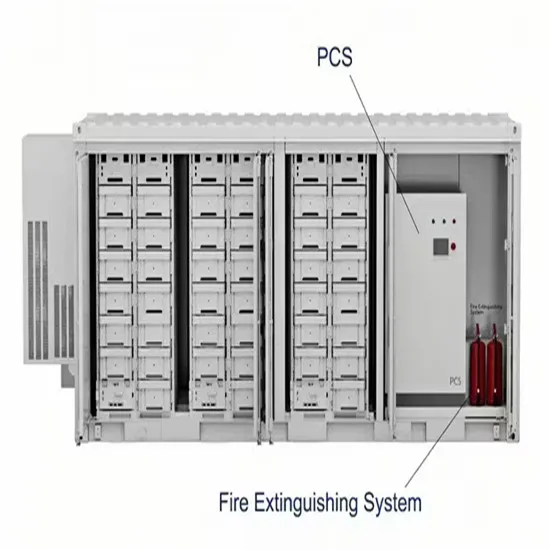

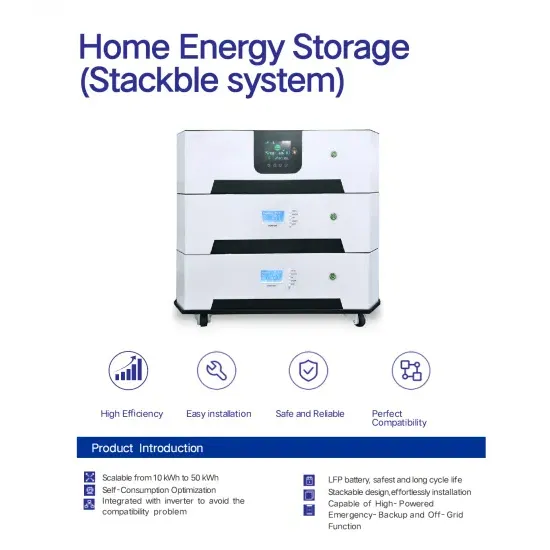

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.