Design for Assembly and Disassembly of Battery Packs

Aug 23, 2019 · Lithium-Ion Batteries (LIB) are batteries where the anode is for instance Lithium Cobalt Oxide (LCO) and the negative terminal is graphite. (36) LIB are complex products that

Get Started

Lithium-Ion Battery Assembly Process & Key

May 17, 2025 · Discover the key stages in the lithium-ion battery assembly process, from raw materials to pack assembly. Learn how battery-making

Get Started

derickwatts

ACEY New Energy Technology, founded in 2009, is a one-stop supplier specialized in manufacturing advanced machineries and offering the best tailored solutions for lithium-ion

Get Started

Innovating battery assembly

Aug 13, 2025 · EV batteries have become an integral part of the vehicle structure, making lithium-ion cell assembly and their integrity a safety-critical issue. One major diferentiating feature of

Get Started

Battery Pack Assembly & Manufacturer

5 days ago · Battery pack assembly by Australia''s largest battery pack manufacturer. Manufacturing battery packs using lithium ion, lithium iron

Get Started

Important information for people buying

Aug 5, 2025 · The last type of lithium-ion battery to be aware of is the lithium titanate (LTO) pack. Despite being one of the oldest types of lithium-ion

Get Started

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

Get Started

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · In this guide, we''ll walk you through everything you need to know – from the basics of what a battery pack is, to the tools and materials required, the step-by-step assembly

Get Started

Lithium titanate batteries for sustainable energy storage: A

The cooling process in a lithium titanate oxide lithium-ion battery pack was demonstrated by Madani et al. [92] through experimental measurement of the heat production inside lithium

Get Started

Beginner-Friendly Tips for Assembling Lithium

May 7, 2025 · Effective planning lays the foundation for a reliable lithium battery pack. You should start by defining the application requirements, such as

Get Started

LTO Batteries: Benefits, Drawbacks, and How They Compare

Apr 18, 2025 · The lithium titanate battery, commonly referred to as LTO (Lithium Titanate Oxide) battery in the industry, is a type of rechargeable battery that utilizes advanced nano-technology.

Get Started

LITHIUM BATTERY PACK PROCESS ASSEMBLY

A lithium-titanate battery is a modified lithium-ion battery that uses lithium-titanate nanocrystals, instead of carbon, on the surface of its anode. This gives the anode a surface area of about

Get Started

48V Lithium titanate oxide (LTO) battery pack

Aug 1, 2025 · LTO Battery refers to a lithium titanate battery, which is a lithium-ion secondary battery that uses lithium titanate as the negative electrode material

Get Started

Lithium titanate battery package assembly

The invention discloses a lithium titanate battery assembly structure, and particularly relates to the technical field of battery assembly, which comprises an external protection frame plate,

Get Started

Understanding Lithium Titanate Battery Safety: Compliance

Apr 11, 2025 · How Do Lithium Titanate Batteries Meet Global Safety Standards? Lithium titanate (LTO) batteries meet global safety standards through superior thermal stability, non-flammable

Get Started

Experimental study of an air-cooled thermal management

Oct 15, 2012 · Previously, we showed that a liquid-cooled thermal management system is a viable option for the active cooling of lithium–titanate batteries [3]. It was also realized that any liquid

Get Started

Lithium Titanium Oxide

Aug 16, 2022 · Lithium Titanium Oxide, shortened to Lithium Titanate and abbreviated as LTO in the battery world. An LTO battery is a modified lithium

Get Started

Custom Battery Pack Design & Assembly

Jun 13, 2024 · We could design custom lithium primary battery pack with bobbin type lithium thionyl chloride battery cells and hybrid pulse capacitors based on customer''s requirements.

Get Started

Lithium-ion battery packs | VARTA AG

4 days ago · In the Power Pack Solutions division, VARTA develops rechargeable standard and customized lithium-ion battery packs. Regardless of the technology or the complexity of the

Get Started

A microscale soft lithium-ion battery for tissue

Oct 25, 2024 · Here the authors present a microscale soft rechargeable lithium-ion battery based on the lipid-supported assembly of silk hydrogel droplets

Get Started

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Conclusion Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this

Get Started

Understanding LTO Batteries: A Comprehensive Guide

Aug 12, 2024 · Lithium Titanate Oxide (LTO) batteries offer fast charging times, long cycle life (up to 20,000 cycles), and excellent thermal stability. They are ideal for applications requiring rapid

Get Started

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Diferent shapes of the lithium-ion cell Nomenclature of lithium-ion cell/battery Overview of Li-ion battery packs Assembling Process Detailed flowchart for Li-ion battery pack

Get Started

Battery Module: Manufacturing, Assembly and

Dec 28, 2022 · In the Previous article, we saw the first three parts of the Battery Pack Manufacturing process: Electrode Manufacturing, Cell Assembly, Cell

Get Started

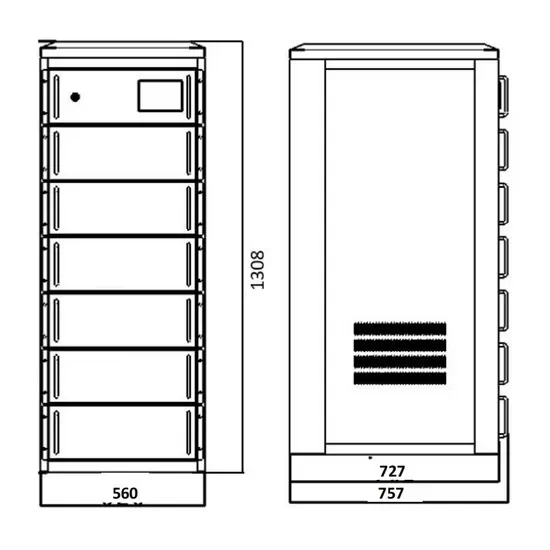

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · , this brochure presents the process chain for the production of battery modules and battery packs. The individual cells are connected in series or parallel in a module. Several

Get Started

Specifying LTO battery cell chemistry can be vital

Nov 14, 2024 · In summary Lithium Titanate (LTO) batteries offer numerous advantages over other lithium chemistries, including superior safety, extended

Get Started

Energy-storage Lithium-Titanate (LTO) Battery

7. Easier assembly into battery packs, battery modules for higher energy need The single lithium titanate battery cells can be assembled into lithium titanate

Get Started

Assembly of lithium iron phosphate titanate battery

de as lithium-ion batteries go, around 50-80 Wh/kg. In these batteries, lithium titanate is used in the anode in place of carbon, which allows electrons to enter and exit the anode arly well

Get Started

6 FAQs about [Assembly of lithium titanate battery pack]

What is the production process of lithium-ion battery cells?

"Production process of lithium-ion battery cells" , this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain

What is the process chain for the production of battery modules?

, this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain Overview of the production sequence from cell to system

What is a high-performance lithium battery pack?

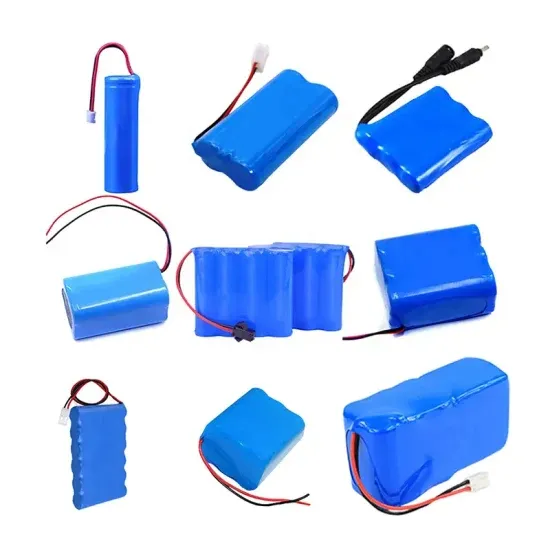

As the world transitions towards sustainable energy solutions, the demand for high-performance lithium battery packs continues to soar. At the heart of this burgeoning industry lies a meticulously orchestrated assembly process, where individual lithium-ion cells are transformed into powerful energy storage systems.

What is a lithium battery management system (BMS)?

The cells within a lithium battery pack are typically arranged in series or parallel configurations to achieve the desired voltage and capacity. Additionally, a Battery Management System (BMS) is often integrated to monitor and ensure the safe operation of the battery pack.

What is quality control in lithium battery assembly?

Quality control is a cornerstone of the lithium battery pack assembly process. At every stage, inline testing and inspection stations meticulously verify the integrity of the cell connections, ensuring that each weld or bolt meets the highest standards for electrical conductivity and mechanical strength.

Are competencies transferable from the production of lithium-ion battery cells?

In addition, the possible transferability of competencies from the production of lithium-ion battery cells is illuminated. 2ndedition ISBN 978-3-947920-29-7 Ed. PEM of RWTH Aachen University & VDMA

Related Articles

-

Bahrain wide temperature lithium titanate battery pack

Bahrain wide temperature lithium titanate battery pack

-

Columbia lithium battery assembly 36v battery pack

Columbia lithium battery assembly 36v battery pack

-

100kwh lithium titanate battery pack weight

100kwh lithium titanate battery pack weight

-

Eastern European Solar Lithium Battery Pack

Eastern European Solar Lithium Battery Pack

-

Lithium battery pack field changes

Lithium battery pack field changes

-

Guatemala Lithium Battery Pack Supplier Company

Guatemala Lithium Battery Pack Supplier Company

-

16500 lithium battery pack

16500 lithium battery pack

-

Praia regular lithium battery pack factory price

Praia regular lithium battery pack factory price

-

Vilnius 26650 lithium battery pack

Vilnius 26650 lithium battery pack

-

What is the mc mark on the front of the lithium battery pack

What is the mc mark on the front of the lithium battery pack

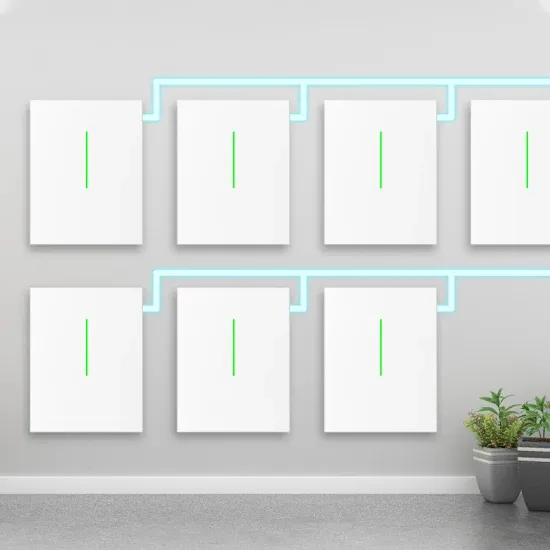

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.