Liquid Cooling Battery Cabinet: Modern BESS Technology

The adoption of a Liquid Cooling Battery Cabinet is a defining feature of next-generation BESS, offering unparalleled control over the operating environment. This advanced Battery Cabinet

Get Started

Liquid Cooled Energy Storage Cabinet

Liquid Cooled Energy Storage Cabinet integrates a battery system, advanced liquid cooling technology, and intelligent management to achieve precise

Get Started

CATL EnerOne 372.7KWh Liquid Cooling battery

Aug 12, 2025 · With the support of long-life cell technology and liquid-cooling cell-to-pack (CTP) technology, CATL rolled out LFP-based EnerOne in 2020,

Get Started

2.5MW/5MWh Liquid-cooling Energy Storage System

Oct 29, 2024 · The liquid cooling thermal management system for the energy storage cabin includes liquid cooling units, liquid cooling pipes, and coolant. The unit achieves cooling or

Get Started

Energy Storage System Cooling

May 5, 2025 · These groups of batteries are connected in a parallel circuit, allowing one battery group to be taken offline for repair or replacement without removing the availability of back-up

Get Started

Battery Liquid Cooling System Overview

1 day ago · Electric motors, supercharging, fast charging, and related tech are innovating rapidly. This is creating big challenges for battery thermal

Get Started

Liquid-cooled energy storage battery cabinet test

ed Battery Cabinet is at the forefront of this transformation. This innovative liquid cooling energy storage represents a significant leap in energy storage technology, offering unmatched adva

Get Started

Battery Energy Storage System Cooling

Kooltronic offers innovative cooling solutions for battery cabinets and electrical enclosures used in renewable energy storage systems. Click to learn more.

Get Started

125KW/261KWh Liquid-Cooling Energy Storage All

Apr 28, 2024 · GB/T 34131-2017 Technical Specification of Lithium-ion Battery Management System for Electrochemical Energy Storage Power Station GB/T 34120-2017 Electrochemical

Get Started

Requirements and calculations for lithium

Jun 11, 2022 · For liquid cooling systems, the basic requirements for power lithium battery packs are shown in the items listed below. In addition, this article is

Get Started

What does the liquid cooling energy storage cabinet

The internal battery pack liquid cooling system includes liquid cooling plates,pipelines and other components. This article will introduce the relevant knowledge of the important parts of the

Get Started

125KW/233KWh Liquid-Cooling Energy Storage

Dec 30, 2024 · The battery container adopts an energy cube structure, and each energy cube is equipped with a water cooler, inverter, and fire control system; the battery module meets the

Get Started

Frontiers | Research and design for a storage

Aug 9, 2024 · Based on the device status and research into industrial and commercial energy storage integrated cabinets, this article further studies the

Get Started

Technical requirements for direct cooling and heating of battery cabinets

WEVJ | Free Full-Text | Investigation of the Liquid Cooling and Heating of a Lithium-Ion Battery The temperature of an electric vehicle battery system influences its performance and usage

Get Started

Battery Cabinet Cooling Requirements | HuiJue Group E-Site

Battery cabinet cooling requirements have become the linchpin of modern energy infrastructure. A single temperature spike beyond 45°C can trigger irreversible capacity loss – but is forced air

Get Started

Energy Storage Battery Pack Enclosure size optimization and

May 9, 2025 · In-depth analysis of ESS Battery Enclosure size matching and compatibility optimization technology, covering large-capacity battery cells, CTP integration, liquid cooling

Get Started

Liquid-cooled Storage Battery Cabinet for Industrial and

Safety certifications and fire prevention standards dominate regulatory requirements for liquid-cooled battery cabinets. UL 9540 (Energy Storage Systems and Equipment) and IEC 62619

Get Started

Liquid Cooling Systems: Enhancing EV Battery

Oct 17, 2024 · Liquid cooling systems offer a highly effective and reliable approach to maintaining optimal battery temperatures. By efficiently

Get Started

REQUIREMENTS AND CALCULATIONS FOR LITHIUM BATTERY LIQUID COOLING

Can lithium-ion battery thermal management technology combine multiple cooling systems? Therefore, the current lithium-ion battery thermal management technology that combines

Get Started

Liquid cooling energy storage requirements

s of liquid cooling is water conservation. Air-cooled data centers typically require assive amounts of water for their cooling. Liquid cooling, by contrast, is more s scenarios for solar battery

Get Started

125KW/233KWh Liquid-Cooling Energy Storage

Dec 30, 2024 · Technical requirements for device selection, functional design, etc. for battery system, PCS, liquid cooler, BMS and high-voltage box.

Get Started

Design requirements for liquid cooling energy storage

ACS Liquid Cooling Cold Plate Requirements Document terminology, identifies liquid cooling component selection with parameters of importance, and contains requirements that future

Get Started

Industrial and Commercial Energy Storage | GSL Energy Certified Liquid

Dec 11, 2024 · Explore GSL Energy''s certified liquid-cooled outdoor lithium-ion battery cabinets, offering up to 372kWh capacity with UL9540, UL1973, and IEC62619 certifications. Designed

Get Started

Liquid Cooling Battery Cabinet: Maximize Efficiency Now

Excessive heat can significantly degrade battery health, reduce efficiency, and pose serious safety risks. To address this, the industry is increasingly turning to advanced solutions like the

Get Started

Liquid-cooled Storage Battery Cabinet for Industrial and

What are the primary end-user industries driving demand for liquid-cooled battery cabinets, and how do their requirements differ? The demand for liquid-cooled battery cabinets in industrial

Get Started

EGS215 Liquid Cooling Battery Energy Storage System

Feb 11, 2025 · This manual primarily introduces the 215kWh industrial and commercial liquid-cooling energy storage ba ery all-in-one cabinet, covering product introduc- on, transporta on,

Get Started

LIQUID-COOLED POWERTITAN 2.0 BATTERY ENERGY

Aug 21, 2024 · A patented liquid-cooled heat dissipation scheme and 4D sensing technology maintain a balanced system temperature with a ≤ 2.5°C temperature difference across all

Get Started

Liquid Cooling: Efficiency in Battery Storage

The solution to this challenge is the advanced Liquid Cooling Battery Cabinet, a technology designed to provide precise and uniform temperature control, ensuring optimal performance

Get Started

Liquid Cooling Battery Cabinet by Hicorenergy

The Future of Energy Storage: The Role of Advanced Cooling As the demand for high-capacity energy storage continues to surge across commercial and industrial sectors, the technology

Get Started

6 FAQs about [Battery cabinet liquid cooling technical requirements]

How to choose a coolant type for a battery pack cooling system?

Confirm the coolant type based on the application environment and temperature range. The total number of radiators used in the battery pack cooling system and the sum of their heat dissipation capacity are the minimum requirements for the coolant circulation system.

Why is water cooling important for lithium ion batteries?

bility is crucial for battery performance and durability. Active water cooling is the best thermal management method to improve the battery pack performances, allowing lithium-ion batteries

How to design a power lithium battery thermal management system?

There are two design goals for the thermal management system of the power lithium battery: 1) Keep the inside of the battery pack within a reasonable temperature range; 2) Ensure that the temperature difference between different cells is as small as possible. In the design of a project, the first step must be to clarify the customer's needs.

How to choose a cooling system?

The overall design, according to the input requirements, generally considers the frame of the cooling system. According to the system heating power density and sealing, allowable temperature range, cost requirements, etc., select a suitable cooling method, and preliminarily determine the type of radiator and heating method.

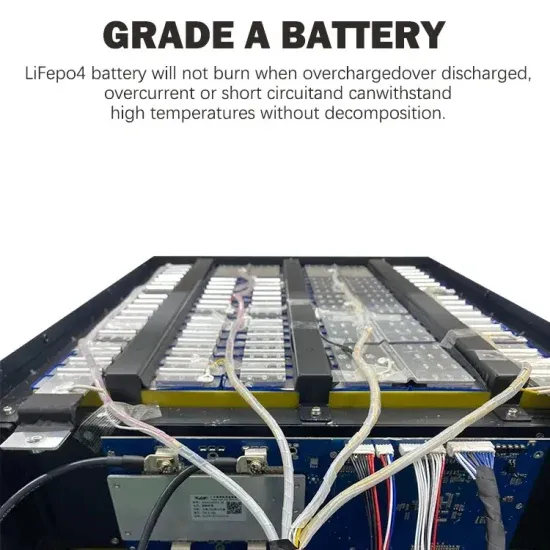

What are the types of components in a battery pack?

The types of components in the battery pack generally include cells, high and low voltage wires, structural components for fixing cells, radiators for cooling systems, cooling system pipelines, battery boxes, battery management systems BMS, and sensors. The following table is a general classification of the materials in the box by the case authors.

What happens if the battery pack temperature is too low?

When the temperature of the battery pack is too low, the battery pack is not allowed to discharge, and the vehicle owner is required to turn on the external power supply to supply power to the heating system in the battery pack, and the vehicle is in a prohibited state.

Related Articles

-

Liquid cooling of energy storage battery cabinet

Liquid cooling of energy storage battery cabinet

-

Energy storage liquid cooling battery cabinet technology development

Energy storage liquid cooling battery cabinet technology development

-

New energy liquid cooling energy storage battery cabinet 80 degrees

New energy liquid cooling energy storage battery cabinet 80 degrees

-

Liquid Cooling Energy Storage Self-service Battery Cabinet

Liquid Cooling Energy Storage Self-service Battery Cabinet

-

Will there be liquid in the battery of the energy storage cabinet

Will there be liquid in the battery of the energy storage cabinet

-

Battery cabinet material requirements

Battery cabinet material requirements

-

New energy battery cabinet photovoltaic water cooling

New energy battery cabinet photovoltaic water cooling

-

Battery cabinet storage site warning requirements

Battery cabinet storage site warning requirements

-

Liquid cooling energy storage cabinet structure

Liquid cooling energy storage cabinet structure

-

Battery cabinet cooling system ESS power base station

Battery cabinet cooling system ESS power base station

Commercial & Industrial Solar Storage Market Growth

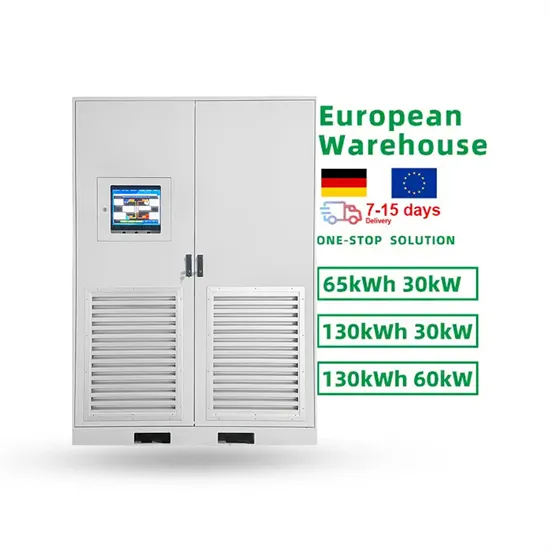

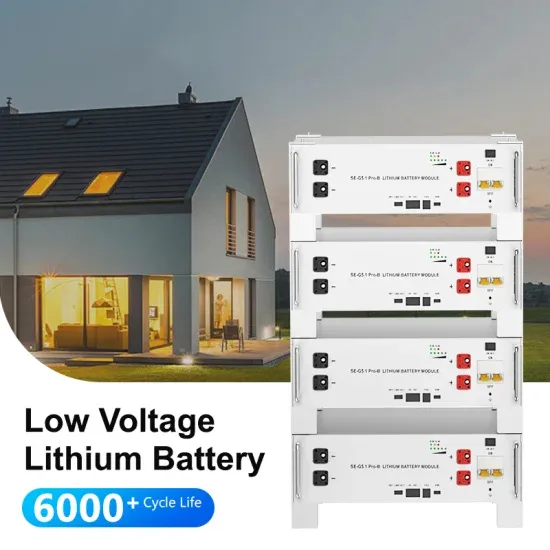

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.