What Are the Raw Materials for Lithium-Ion Batteries?

Jan 4, 2024 · The primary raw materials for lithium-ion batteries include lithium, cobalt, nickel, manganese, and graphite. Lithium serves as the key component in the electrolyte, while cobalt

Get Started

Lithium-Ion Battery Supply Chain

Jan 11, 2025 · The lithium-ion battery supply chain is a specialized subset of the electric vehicle battery supply chain. It encompasses the sourcing of raw materials, manufacturing of lithium

Get Started

Introduction to lithium battery manufacturing

Jul 9, 2023 · This article will introduce the lithium battery manufacturing process in detail, from raw material preparation to final product testing, and break it

Get Started

Raw Materials in Lithium-Ion Batteries Explained

2 days ago · Discover the essential raw materials like lithium, cobalt, nickel, and graphite that power lithium-ion batteries ⚡. Learn about extraction, processing, and sustainability practices

Get Started

From Raw Materials to Finished Product: The

Nov 10, 2024 · Getting raw materials like lithium, cobalt, nickel, and manganese is the first stage of the process of lithium battery production. The individual use

Get Started

Raw materials for lithium battery energy storage power

What materials are used to make a lithium battery? the first stage of the process of lithium battery production. The individual use of each of these aterials will determine the lithium battery''s end

Get Started

Battery Raw Materials: Latest Prices, Market

5 days ago · Battery raw material prices, news and market analysis. Get the latest on lithium, cobalt, nickel and more from our team of battery raw materials

Get Started

McKinsey: EV Growth Tests Raw Material Supply Chains

Jan 6, 2025 · The surge in electric vehicles (EVs) and renewable energy is driving a relentless demand for critical raw materials, putting immense pressure on supply chains. A McKinsey

Get Started

Critical raw materials in Li-ion batteries

Mar 25, 2021 · Introduction In our daily lives, we use products derived from many different metals, minerals and natural materials. The European Commission maintains a list of so-called ''critical

Get Started

Inside Li-ion Battery Production: From Raw

Mar 23, 2025 · From raw material refinement to final cell formation, every gram and joule matters in the lithium-ion economy. As battery demand grows 27%

Get Started

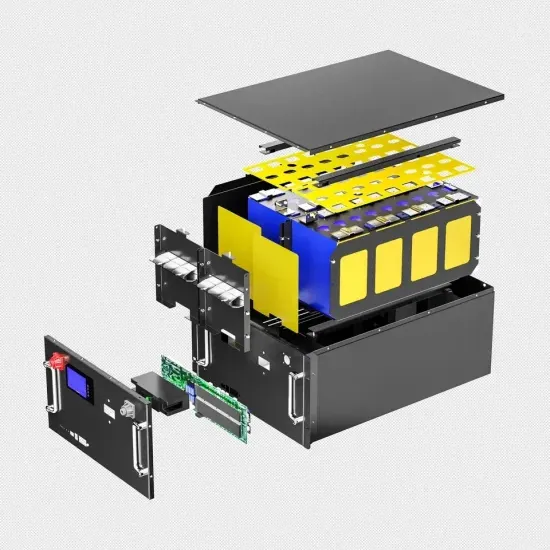

Lithium battery energy storage cabinet processing

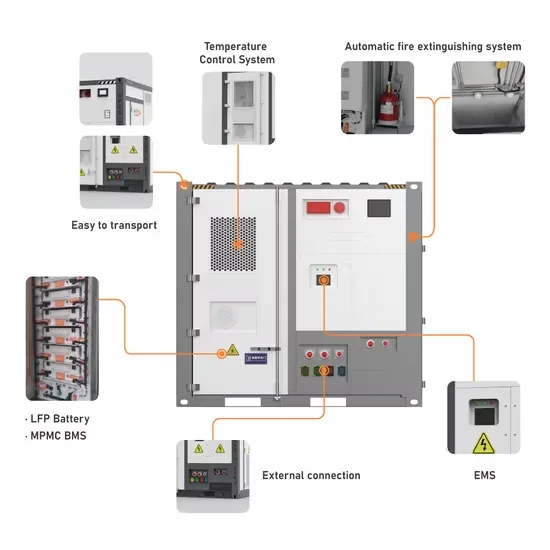

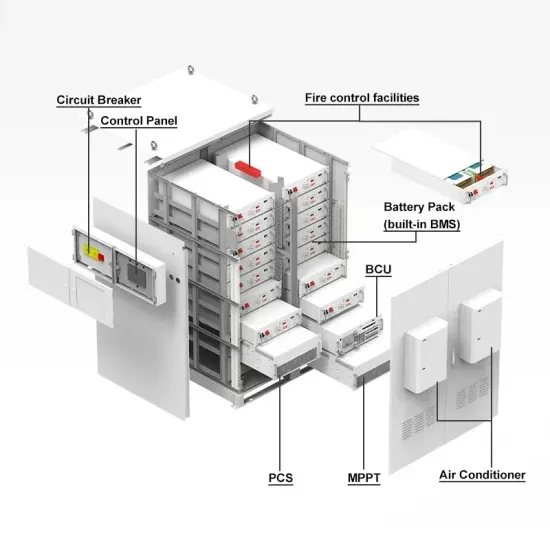

The Vertiv HPL lithium-ion battery cabinet is a safe,reliable,and cost-effective solution for high-power energy storage. It offers improved performance over traditional valve-regulated lead

Get Started

Battery Storage Cabinets: The Backbone of Safe

Apr 11, 2025 · Battery storage cabinets are integral to maintaining the safety and efficiency of lithium-ion batteries. They provide a controlled environment that

Get Started

Lithium-Ion Battery Charging Safety Cabinet

Justrite''s Lithium-Ion Battery Charging Cabinet is engineered to charge and store lithium batteries safely, mitigating common risks during charging.

Get Started

What Are the Essential Raw Materials for Lithium

May 3, 2025 · Lithium-ion batteries rely on materials like lithium, cobalt, nickel, graphite, and manganese for energy storage, stability, and performance in

Get Started

Lithium as a Battery Raw Material

Jul 24, 2025 · Lithium is an indispensable raw material for the production of modern batteries used in electric cars, smartphones, and laptops. In its latest white paper, "Lithium as a Battery

Get Started

asecos: ION-LINE safety storage cabinets

Safety storage cabinets for passive or active storage of lithium-ion batteries according to EN 14470-1 and EN 1363-1 with a fire resistance of 90 minutes

Get Started

Comprehensive review of lithium-ion battery materials and

Oct 1, 2024 · Also, innovating battery design and manufacturing processes to improve battery life, enhance energy density, and reduce costs. Finally, focusing on the sustainability aspect,

Get Started

Choosing the Right Lithium Ion Battery Cabinet:

May 1, 2025 · Ensure maximum safety and efficiency with this in-depth guide on selecting a lithium ion battery cabinet. Learn key features, regulations, and

Get Started

Understanding the Raw Materials Behind Lithium-Ion Batteries

Mar 10, 2025 · The ongoing exploration of new materials and sustainable practices will not only enhance the efficiency and safety of lithium-ion batteries but also address the pressing

Get Started

McKinsey: Is the 2030 Battery Supply Sustainable?

Jan 6, 2025 · McKinsey reveals 2030 battery raw material outlook on lithium, nickel and cobalt as demand for these materials may soon outstrip base-case supply The electrification of vehicles

Get Started

Justrite Lithium Ion Battery Storage Charging

Jul 23, 2024 · The Justrite Lithium-Ion Battery Charging Cabinet is the ultimate solution for safely charging and storing your lithium-ion batteries. Each

Get Started

Decarbonizing lithium-ion battery primary raw

Nov 20, 2024 · The demand for raw materials for lithium-ion battery (LIB) manufacturing is projected to increase substantially, driven by the large-scale

Get Started

What Are The Raw Materials Of Lithium Batteries? | Suny Group

Jul 4, 2022 · Lithium batteries are an important part of electric vehicles, mobile phones and other products. Understanding the resulting raw materials of lithium batteries will help us better

Get Started

Battery cabinets are process materials

A well-designed lithium ion battery cabinet includes features like fire-resistant materials, proper ventilation, and integrated safety mechanisms. These features help mitigate

Get Started

What Are the Essential Raw Materials for Lithium

May 3, 2025 · Lithium-ion batteries depend on critical raw materials like lithium, cobalt, nickel, graphite, and manganese. Each material contributes uniquely to

Get Started

Raw Materials and Recycling of Lithium-Ion

Feb 6, 2024 · A comprehensive understanding of material flows and end-of-life battery management is essential to establish a sustainable, durable, and

Get Started

The Lithium-Ion (EV) battery market and supply chain

Apr 5, 2022 · Drivers for Lithium-Ion battery and materials demand: Large cost reduction expectations Technology progress in batteries goes along with a broader proliferation of cell

Get Started

What Impact are EVs and Renewables Having on Raw Materials?

Jan 14, 2025 · The most impacted raw materials Lithium is crucial for battery production, with more than 80% of global lithium consumption currently by battery manufacturers. McKinsey

Get Started

The Lithium-Ion (EV) battery market and supply chain

Apr 5, 2022 · Market drivers and emerging supply chain risks April, 2022 Drivers for Lithium-Ion battery and materials demand: Large cost reduction expectations 07/08-2021 Batteries are key

Get Started

Battery cabinets are process materials

What is the battery manufacturing process? The battery manufacturing process is a complex sequence of steps transforming raw materials into functional, reliable energy storage units.

Get Started

6 FAQs about [Lithium battery station cabinet raw materials]

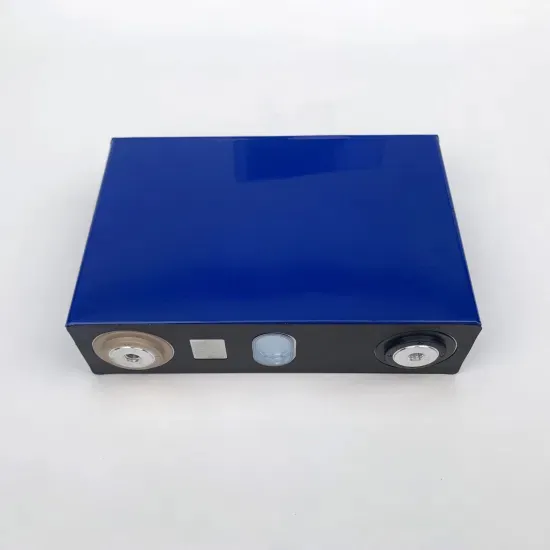

What materials are used to make a lithium battery?

Getting raw materials like lithium, cobalt, nickel, and manganese is the first stage of the process of lithium battery production. The individual use of each of these materials will determine the lithium battery’s end performance. Lithium: Mining through mineral ores like spodumene or extracted from lithium-rich brine found under salt flats.

Why are lithium-ion batteries important?

Lithium-ion batteries are the most used batteries worldwide. This is because they are known as an important technology for sustainable and efficient power solutions. Due to its highly increasing demand in many industries, the question is raised: How to make a lithium battery and its battery production process?

How Li ion batteries are manufactured?

From obtaining raw lithium brine and extracting and purifying raw material to manufacturing and testing Li-ion cells to assembling the cells and testing battery packs, as well as then shipping them to customers, each step of the li ion battery manufacturing process is critical to producing safe, reliable, and high-performance products.

How to reduce the cost of lithium ion batteries?

Another great practice to mitigate the issues is by the decreasing the consumption of raw materials also help to reduce the cost, and this is gained by investing more in the increase in the rate of battery recycling resulting long life of battery and results in less carbon footprint created by lithium ion batteries.

What is a lithium battery pack?

The Lithium battery pack may be used in the end product, such as electrical vehicles, portable devices, etc. The battery pack manufacturing process plays an important vital role in making li-ion batteries highly efficient, reliable, environmentally friendly, and mainly safe, for consumer and industrial applications.

How is a lithium ion battery manufactured?

Manufacturing lithium ion batteries is a complex procedure that involves a lot of activity. The lithium battery manufacturing process—required for each cell—includes lengthy, reproducible, and useful engineering and quality control steps.

Related Articles

-

Nordic lithium battery replacement station cabinet system

Nordic lithium battery replacement station cabinet system

-

Full-charge voltage of lithium iron phosphate battery station cabinet

Full-charge voltage of lithium iron phosphate battery station cabinet

-

Lithium battery station cabinet round

Lithium battery station cabinet round

-

Lithium battery station cabinet base station energy equipment field analysis

Lithium battery station cabinet base station energy equipment field analysis

-

Lithium battery station cabinet magic use

Lithium battery station cabinet magic use

-

Lithium battery station cabinet base station energy price

Lithium battery station cabinet base station energy price

-

Which lithium iron phosphate battery station cabinet is better

Which lithium iron phosphate battery station cabinet is better

-

Energy storage lithium iron phosphate battery station cabinet for sale

Energy storage lithium iron phosphate battery station cabinet for sale

-

Sana outdoor lithium battery station cabinet design

Sana outdoor lithium battery station cabinet design

-

Libreville lithium battery station cabinet customization company

Libreville lithium battery station cabinet customization company

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.