Pack Sizing and Requirements

Jul 4, 2025 · Initial sizing is around Electrical and Thermal. For a given cell can we get to a series and parallel configuration that meets the power demand? How fast do the cells heat up? What

Get Started

Battery Pack Design: From Cell Selection to Pack Materials

Aug 13, 2025 · Battery selection and battery pack design to meet performance targets have become critical factors for engineers across multiple sectors. From designing hand-held power

Get Started

Multi-Criteria decision making (MCDM) for the

Aug 1, 2020 · The method is useful for the EV OEMs (Original Equipment Manufacturers) in selection of the best battery, and to optimize the cost, and

Get Started

Comparative Material Selection of Battery Pack Casing for

Dec 4, 2023 · Abstract: This paper discusses the battery pack thermal management components for electric vehicles that are necessary for the batteries to operate effectively in all weather.

Get Started

Battery Sizing Explained

Oct 11, 2022 · The battery can be categorized according to the material used, including lithium-ion, lithium polymer, nickel-cadmium, and nickel-metal

Get Started

Battery Pack Design: Efficient & Safe Energy

Mar 15, 2025 · Battery pack design is crucial for electric vehicles (EVs) and energy storage systems. A well-designed battery pack ensures efficiency,

Get Started

Battery Packs Explained: How They Work, Usage, and a

Feb 28, 2025 · Select a battery pack that fits comfortably in your application without being overly heavy. For example, ultralight battery packs are ideal for backpacking, while heavier packs

Get Started

Lithium Battery Pack Designer

Aug 6, 2025 · About Our Battery Pack Designer Our battery pack designer tool is a web-based application that helps engineers and DIYers build custom DIY battery packs various electronic

Get Started

CELL SELECTION & SOURCING | Mobile Power Solutions

At the heart of any battery pack, is the Lithium or Lithium-ion cell. Choosing the optimal cell for your battery pack can determine the success or failure of a mobile device. The selection of the

Get Started

Battery Pack Design: From Cell Selection to Pack Materials

Aug 13, 2025 · Learn how the new Battery Designer tool in Ansys Granta Selector enables you to select cells from a standard database, carry out early-stage design and performance

Get Started

Airport Battery Pack Selection Guide

Finally, foldable designs will ensure the battery pack is compact, lightweight and efficient. In conclusion, these factors should be considered when selecting an

Get Started

Battery Pack Design Considerations for Performance and

2 days ago · At the conclusion of our webinar, Custom Battery Pack Design Considerations for Performance and Safety, we had several questions submitted to our presenter, Battery

Get Started

PACK是什么意思?电池包PACK是什么?

May 14, 2021 · 电池包PACK是一种锂离子电池的制作工艺,电池PACK一般指的是组合的锂离子电池组,包括包装、封装和装配。在PACK行业,安照客户要求

Get Started

Battery Selection, Safety, and Monitoring in Mobile

Jun 26, 2007 · Battery Selection, Safety, and Monitoring in Mobile Applications Yevgen Barsukov, Texas Instruments ABSTRACT The battery is often considered by engineers as a constant

Get Started

E-MOBILITY OVERCURRENT PROTECTION GUIDE

Aug 1, 2024 · E-Mobility transportation means are now being mass-marketed; safety and reliability are the most important priorities for the vehicles and their occupants. For all variations of

Get Started

MSD function and selection of power battery

Nov 9, 2021 · The beginning of the MSD in the Power Battery System Pack gradually becomes standard from optional, this process is not too long, in

Get Started

Selection of the battery pack parameters for an

Jun 1, 2017 · Selection of the battery pack parameters for an electric vehicle based on performance requirements June 2017 IOP Conference Series

Get Started

Power Battery Pack Design Process

Jun 28, 2024 · Define the physical dimensions, weight, and shape specifications of the battery pack. 2. Battery Selection: Choose the appropriate battery type based on requirement

Get Started

How to Select Battery for Electric Vehicle [ Key

Nov 13, 2024 · Choosing the right battery for your electric vehicle is crucial. Read our guide to find out what to look for and make an informed decision for your EV.

Get Started

EV battery sizing calculator

Jan 8, 2024 · Battery Pack Parameters Results ⓘ Based on the input data for cell specification and vehicle data, the main parameters of the battery pack are calculated for easy comparison.

Get Started

Multi-criteria decision making (MCDM) for the selection of Li

Jan 1, 2021 · The practical issue is that the EV manufacturers do find it difficult to select a best Li-ion battery, in order to strike a trade-off between performance, cost, and life. In this paper, an

Get Started

Mechanical Design of Battery Packs

24:34 - Overview of material selection for battery pack Key Takeaways - Battery pack design involves considering electrical, mechanical, thermal aspects and the Battery Management

Get Started

PACK电池包基础知识大盘点

Aug 10, 2023 · 什么叫PACK电池包? 首先要了解锂电池单体、锂电池模组和锂电池包的大致区分: 电池单体 (cell): 组成电池组和电池包的最基本的元素,一

Get Started

EnPower Battery Pack Design Software for EV Cell Selection

EnPower™ is a web-based application that ensures the best battery cell model is selected for your electric vehicle application before embarking on the extensive battery pack modeling

Get Started

(PDF) Material selection and assembly method

Jan 1, 2018 · The main costs of which are battery cells and assembling processes. The battery cell is indeed priced from battery manufacturers while

Get Started

ESS''s Battery Pack Design Checklist: Your

Apr 26, 2025 · Streamline your battery pack development with ESS''s Battery Pack Design Checklist. Learn how to integrate safety, reliability and

Get Started

How to Choose the Right Li-ion Battery Pack for

Selecting the right Li-ion battery pack depends on voltage, capacity, chemistry, discharge rate, and application. By understanding these factors, you can

Get Started

Electric Motor Batteries: Selection, Performance,

Apr 9, 2025 · Discover how to select the best electric motor batteries for optimal performance, efficiency, and applications in industries like EVs, robotics, and

Get Started

Battery Packs and Assemblies Selection Guide: Types,

Selecting the right battery pack is crucial and starts with assessing your power needs based on device specifications and lifestyle. Evaluate the energy requirements of your devices, such as

Get Started

Battery Pack Design Essentials

Jun 13, 2025 · In this section, we will discuss the fundamentals of battery pack configuration, including series and parallel configurations, cell selection criteria, and their impact on overall

Get Started

Comparative Material Selection of Battery Pack

This paper discusses the battery pack thermal management components for electric vehicles that are necessary for the batteries to operate effectively in all

Get Started

6 FAQs about [PACK battery selection]

What are battery packs?

Battery packs are constructed from two or more individual cells or batteries. They come in two basic types: primary and secondary or rechargeable. Primary batteries are disposable, non-rechargeable devices that must be replaced once their energy supply is depleted.

What are the two basic types of battery packs?

There are two basic types of battery packs: primary and secondary or rechargeable. Primary batteries are disposable, non-rechargeable devices. They must be replaced once their energy supply is depleted. Battery packs are constructed from two or more individual cells or batteries.

What are the parts of a battery pack?

A battery pack consists of several interconnected parts, each playing a vital role in energy storage and power delivery: Battery Cells – The core energy storage units. Battery Management System (BMS) – Regulates voltage, temperature, and safety. Cooling System – Prevents overheating and maintains efficiency.

How do you design a battery pack?

Designing an efficient and reliable battery pack involves multiple engineering considerations. The following key factors influence performance, safety, and durability. Voltage (V): Total voltage increases when cells are connected in series. Capacity (Ah): Total capacity increases when cells are connected in parallel.

How do I choose the right battery pack for my EV?

Choosing the right battery pack depends on application needs, energy density, weight, and cooling systems. For EVs, high-capacity lithium-ion packs offer efficiency and longevity. A well-designed battery pack improves safety, durability, and efficiency.

What makes a good battery pack?

Designing a reliable, safe and efficient battery pack isn’t just about selecting the right cells or managing heat, it’s about integrating every subsystem into a cohesive, validated system.

Related Articles

-

21v lithium battery pack can

21v lithium battery pack can

-

Air-cooled battery pack

Air-cooled battery pack

-

Can the energy storage cabinet battery be made into a battery pack

Can the energy storage cabinet battery be made into a battery pack

-

Korean electric three-point lithium battery pack

Korean electric three-point lithium battery pack

-

Macedonia 24v lithium battery pack factory

Macedonia 24v lithium battery pack factory

-

ASEAN LiFePO4 Battery Pack

ASEAN LiFePO4 Battery Pack

-

How much does a lithium battery pack cost in Kenya

How much does a lithium battery pack cost in Kenya

-

Pack automation battery

Pack automation battery

-

Huawei Malta cylindrical battery pack direct sales

Huawei Malta cylindrical battery pack direct sales

-

Which kind of Managua lithium battery pack is better

Which kind of Managua lithium battery pack is better

Commercial & Industrial Solar Storage Market Growth

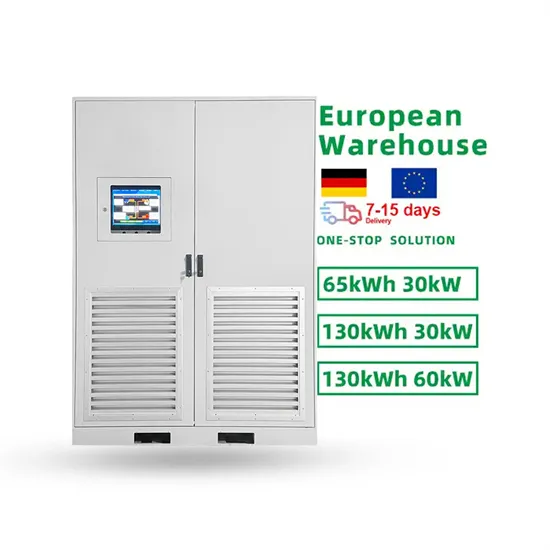

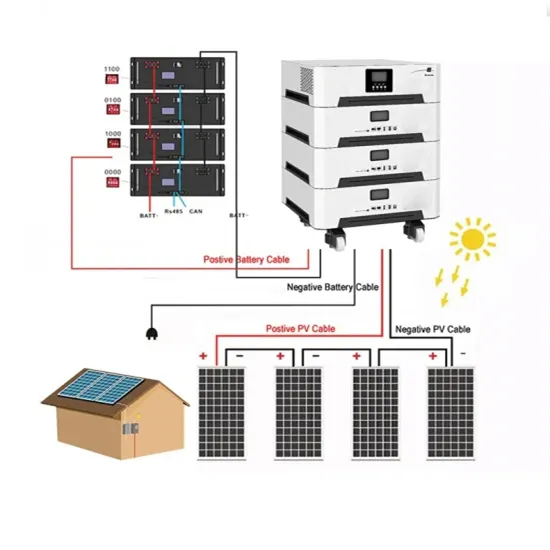

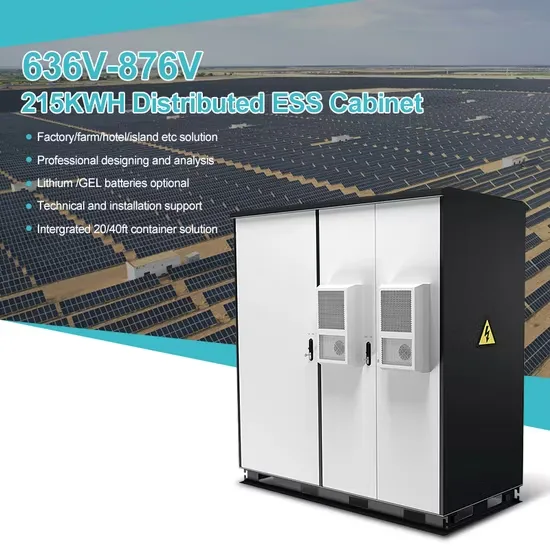

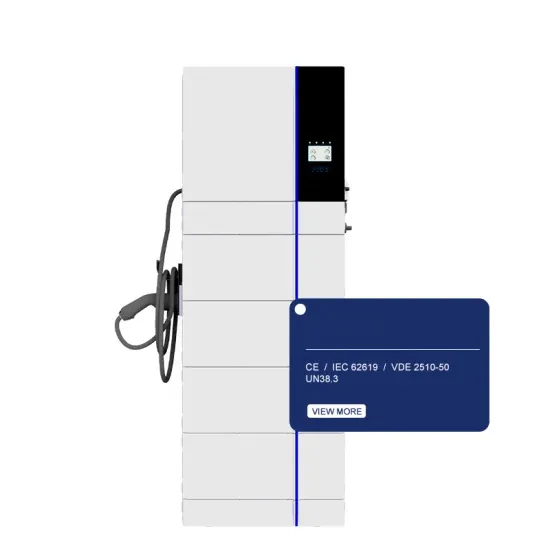

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.