Film Bus Link Capacitors For Inverter

6 days ago · This page presents a practical mathematical approach on how to properly size a bus link capacitor for a high performance hard switched DC to

Get Started

A New Reliable Switched-Capacitor-Based High Step-Up

ABSTRACTThis article presents a new transformerless switched-capacitor (SC) based five-level grid- connected inverter with inherent voltage-boosting capability. The proposed topology

Get Started

Selecting dc-link capacitors for inverters

Feb 9, 2021 · The capacitor voltage rating must exceed the worst-case peak bus voltage as might arise under "high-line" mains conditions, maximum solar

Get Started

Explanation of Inverter DC Capacitance and Inrush Current

Dec 14, 2023 · Explanation of Inverter DC Capacitance and Inrush Current What is Inverter DC Capacitance? All modern power inverters have a large capacitor bank at their DC input

Get Started

Selection and calculation of dclink capacitor in

Dc-link capacitors are considered as one of the sensitive parts of the grid connected photovoltaic systems and needs effort to design a reliable and optimal size capacitor as its reliability is

Get Started

Capacitors for High Power

Mar 21, 2024 · The DC-link capacitor''s purpose is to provide a more stable DC voltage, limiting fluctuations as the inverter sporadically demands heavy current. A design can use different

Get Started

DC-Link design tips: how to choose capacitors

Mar 24, 2021 · DC-Link capacitors are an important step in power conversion for a number of uses, including three-phase Pulse Width Modulation (PWM)

Get Started

Voltage Source Inverter : Construction, Phases

An ideal voltage source inverter keeps the voltage constant through-out the process. Construction A VSI usually consists of a DC voltage source, voltage

Get Started

How to Select DC Link Capacitor

The DC link capacitor is placed between the DC (in this case, the battery) and the AC (which is the load side) of the voltage inverter. The capacitor is placed

Get Started

9–Level switched capacitor–high-voltage gain boosting inverter

Jun 1, 2024 · The method of utilizing switched capacitors stands as an effective approach to achieve elevated voltage levels while minimizing the requirement for numerous DC sources

Get Started

How is inverter bus capacitance chosen?

Dec 5, 2020 · Does anyone know how the bus capacitance of an inverter is chosen? I have been told that a 6kW inverter should have 0.1F from one source, and 0.028F from another source.

Get Started

A DC Bus Capacitor Design Method for Various Inverter

Feb 21, 2024 · Abstract - This paper involves the selection and sizing of the appropriate type of dc bus capacitor for various applications utilizing PWM operated three-phase voltage source

Get Started

Selecting Capacitors for Inverter Applications

This paper will present a practical mathematical approach on how to properly size a bus link capacitor for a high performance hard switched DC to AC inverter using film capacitors and will

Get Started

DC-Link Voltage Stabilization for Reduced DC-Link Capacitor Inverter

Jun 18, 2013 · In conventional motor drive systems using pulsewidth modulation (PWM) inverters, large electrolytic capacitors are used for stabilization of the dc-link voltage. Since the

Get Started

Microsoft Word

Sep 27, 2019 · ABSTRACT DC-link capacitors are used in power electronic switching circuits, including inverter modules for electric drive vehicles, to minimize ripple current and voltage

Get Started

A Wide Input Voltage Range Switched-Capacitor Multilevel Inverter

Aug 30, 2023 · This article presents a wide input voltage range switched-capacitor multilevel inverter based on an adjustable number of output levels. Through different modulation

Get Started

Capacitors in inverter circuitry... | DIY Solar Power Forum

May 26, 2021 · The big caps in an inverter smooth out pulses of current drawn by high frequency step up SMPS (HF inverters) and store the boosted voltage (HF inverters), They smooth the

Get Started

The Inverter

Half of the load capacitance is due to the inverter itself ( intrinsic or self-loading ) and half is due to the fan-out ( extrinsic ) gate capacitance. The extrinsic capacitance dominates the propagation

Get Started

A DC bus capacitor design method for various

Sep 1, 2012 · This paper involves the selection and sizing of the appropriate type of dc bus capacitor for various applications utilizing PWM operated three

Get Started

Basic Knowledge of Film Capacitors

Feb 18, 2022 · For the purpose of voltage stabilization (noise removal, smoothing) of inverter power supplies, film capacitors are essentially required. Because film capacitors also have

Get Started

A Novel High-Gain Switched-Capacitor Multilevel Inverter

Nov 1, 2024 · This paper introduces a novel Multi-Level Inverter (MLI) design which utilizes a single input and leverages capacitor voltages source to generate a four-fold increase in output

Get Started

Switched-Capacitor Voltage Inverters

Apr 30, 2010 · ge-pump voltage inverter (Figure 1). This applica-tion requires only two external components—capacitors C1 and C2—p us a bypass capacitor, if necessary. Refer to the

Get Started

A 13-level switched-capacitor-based multilevel inverter with

Jan 2, 2025 · Compared to other 13-level switched-capacitor inverters, the proposed structure utilizes fewer components, capacitors with lower maximum voltage, and fewer conduction

Get Started

LM27761 Low-Noise, Regulated, Switched-Capacitor

May 30, 2025 · The voltage inverter portion of the LM27761 contains four large CMOS switches which are switched in sequence to invert the input supply voltage. Energy transfer and storage

Get Started

Looking Closer at DC Link Capacitors in Electric

Jul 3, 2024 · It also detects the motor''s speed and position and drives the insulated-gate bipolar transistor (IGBT) power stages. Figure 3. Simplified

Get Started

Selecting and Applying DC Link Bus Capacitors for

May 16, 2023 · Sam G. Parler, Jr., P.E. Cornell Dubilier Abstract, aluminum electrolytic and DC film capacitors are widely used in all types of inverter power systems, from variable-speed

Get Started

What is a DC Link Capacitor? | Capacitor Connect

Jan 28, 2024 · In these circuits, AC or DC source voltage is first converted to DC voltage of suitable level and rectified voltage is fed to a capacitor (DC Link capacitor). The capacitor

Get Started

Capacitor Rating Selection for Voltage Sag

Apr 23, 2025 · Capacitor: DVR has a large DC capacitor to ensure constant input supply to inverter. A large capacitor connected at the input inverter terminals tends to make the input DC

Get Started

6 FAQs about [Voltage inverter large capacitor]

How to sizing capacitors for inverter bus link applications?

The first step in sizing capacitors for inverter bus link applications should be to understand how much bus link capacitance is required for a given inverter design. The biggest design limitation for electrolytic capacitors in inverter applications has been the amount of ripple current that the electrolytic capacitor can sustain.

Does Adding capacitance improve the performance of an inverter?

So beyond a certain point, adding capacitance does little to enhance the performance of the inverter. = 308 uF That’s 16 times less capacitance than that of the electrolytic capacitor! Certainly packaging a 308 uF capacitor verses a 5,000uF capacitor makes for a smaller, lighter and more compact design.

Are film capacitors a good choice for inverter power bridges?

Moreover, modern film capacitors not only perform better but can be a cost effective technology as well if applied correctly. inductance in an inverter power bridge leads to inefficiencies due to the voltage spikes they produce when the power devices are switched on and off at a high rate of dI/dt.

Are electrolytic capacitors good for hard switched inverter bus link capacitors?

Electrolytic capacitors have been the workhorse technology for hard switched inverter bus link capacitors for many years. Electrolytic capacitor technology has also remained virtually unchanged over the years. Up till now, the greatest benefit in using electrolytic capacitors for bus link capacitors in inverters has been their cost.

How many volts is a 380 volt inverter?

The inverter has an output inductance of 380μH per phase and a nominal DC bus voltage of 680 volts. The switching frequency is 3kHz and the ripple voltage must be controlled to within 1% of the bus voltage. The ambient temperature requirements are 450C - 600C typical for 80% of application life and 850C for 20% of application life.

What is a bus link capacitor?

II. THE BUS LINK CAPACITOR’S ROLE The bus link capacitor is used in DC to AC inverters to decouple the effects of the inductance from the DC voltage source to the power bridge. Figures 1A and 1B show two examples of a typical hard switched pulse width modulated (PWM) inverter that converts DC voltage to a three phase AC voltage.

Related Articles

-

Inverter output voltage series capacitor

Inverter output voltage series capacitor

-

Can the inverter high voltage capacitor be charged

Can the inverter high voltage capacitor be charged

-

Does the inverter capacitor increase the voltage

Does the inverter capacitor increase the voltage

-

48-72v super large inverter

48-72v super large inverter

-

High Voltage Inverter Sales in Ireland

High Voltage Inverter Sales in Ireland

-

Adjust the inverter voltage

Adjust the inverter voltage

-

Advantages of choosing a voltage source inverter

Advantages of choosing a voltage source inverter

-

Inverter negative voltage

Inverter negative voltage

-

6kW inverter output voltage

6kW inverter output voltage

-

What is the input voltage of the inverter

What is the input voltage of the inverter

Commercial & Industrial Solar Storage Market Growth

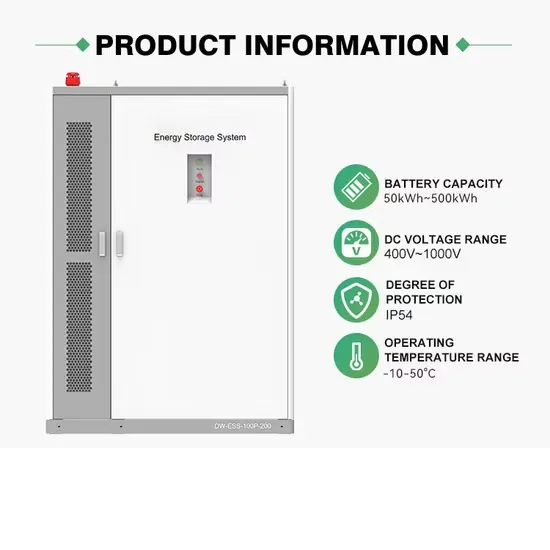

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.