The Development of Rotor Brakes for Wind Turbines

Aug 22, 2017 · Abstract This article introduces the design of a rotor brake that imparts braking force to a rotor disc assembled on the high-speed coupling of a wind turbine, and includes the

Get Started

Wind Turbine Brake Pads: Everything You Need

. Proper attention to the brake pads used in wind turbines is vital to ensure these large structures'' safe and efficient operation. This article will guide you in

Get Started

Mathematical Modeling of Wind Turbine Brake System

Jan 6, 2024 · The mathematical model of the wind turbine brake system can be attributed to the advantages of the mathematical model obtained by taking detailed account of the mechanical

Get Started

Alternative Braking Method for Small Scaled-Wind

May 20, 2022 · Small-wind power generation systems are difficult to operate in strong wind region since the turbine could be over-rotated and damaged if the brake system is not robust enough

Get Started

What are the different types of wind turbine

May 16, 2011 · Pitch drive brakes: A series of high-torque, electrically released, spring engaged, static holding brakes can withstand the conditions on the

Get Started

Smart Braking System for Modern Wind Turbines

Jan 30, 2012 · As shown in Fig.1, the mechanical brake system is normally placed on the high-speed shaft, consisting of a brake disc and a number of calipers driven by a hydraulic system.

Get Started

WIND TURBINE BRAKES

Jun 21, 2024 · Rotor brakes are a good example, as a wind turbine rotor of increased size and more advanced design will need an improved braking system compared to a smaller model.

Get Started

WIND TURBINE BRAKES

Jun 21, 2024 · For a new 10MW wind turbine design, one OEM relied on Stromag to develop a modular rotor brake package that could exert the required 190 kN brake force. Offshore wind

Get Started

Literature Review On Wind Turbines Braking Systems

Dec 9, 2024 · Wind turbine braking systems are essential for controlling and stopping the rotor during maintenance, emergencies, and extreme weather. These systems enable safe and

Get Started

Braking Systems for Wind Turbines

The braking systems of Hydratech Industries Wind Power ensures that the wind turbines yaw and main shaft remains reliable and in safe control. We take a

Get Started

Wind turbine brakes | reducing wind turbine

Aug 13, 2025 · Sustainable Braking is utilised on the mechanical braking infrastructure of wind turbines. It is this braking system that prevents

Get Started

The Brake System and Method of the Small Vertical Axis

Analyzes the braking principle of mechanical and electromagnetic brake, and the method of improved braking system, the improved braking system makes the rotate speed of wind

Get Started

Aerodynamic braking system analysis of

Jul 1, 2020 · The various mechanical braking system and Aerodynamic braking systems are presently used to control the over speeding of the wind turbine at

Get Started

Braking Systems for Wind Energy

DELLNER BUBENZER offers lightweight, noise-free systems for braking and gliding processes in wind turbines. Noise reduction has been the core focus in the development of this

Get Started

Backup Mechanical Brake System of the Wind Turbine

Jan 1, 2018 · Abstract Paper clarifies the necessity of the emergency mechanical brake systems usage for wind turbines. We made a deep analysis of the wind turbine braking methods

Get Started

Aerodynamic braking system analysis of horizontal axis wind turbine

Jan 1, 2020 · The various mechanical braking system and Aerodynamic braking systems are presently used to control the over speeding of the wind turbine at extreme wind velocity. In this

Get Started

Designing and Testing Braking Systems for Wind Turbines

A core component in this mechanical chain is the braking system, which must ensure the safe operation of turbines under varying conditions. The evolution from simple mechanical brakes

Get Started

Influence of mechanical faults in pitch, brake, controller systems

Oct 1, 2023 · Offshore wind turbines (OWTs) have undergone unprecedented development in recent years, and during their service life the control and mechanical systems faults have

Get Started

Fault detection and diagnosis within a wind turbine mechanical braking

Nov 1, 2012 · The present study investigates online condition monitoring based on voltages and currents for mechanical wind turbine brake system fault diagnosis.

Get Started

The Basics of the Wind Turbine Brake System

Jun 8, 2019 · In the wind energy arena, the wind turbine brake system requires greater reliability and better cycle rates to convert kinetic energy into heat.

Get Started

Backup Mechanical Brake System of the Wind

Jan 1, 2018 · Paper clarifies the necessity of the emergency mechanical brake systems usage for wind turbines. We made a deep analysis of the wind

Get Started

Braking Ideas For Wind Turbines

Brakes for wind turbines call for higher cycle rates, higher loads, greater reliability and often in more compact packages than those on conventional factory

Get Started

Dellner Brakes | Wind Systems Magazine

Aug 15, 2020 · By approaching customers with a full-service mentality, Dellner Brakes works to supply the industry with a range of lightweight, noise-free

Get Started

Investigation of Aerodynamic Braking Devices for Wind

Oct 16, 2013 · The use of trailing-edge devices for aerodynamic control of wind turbine rotors has attracted renewed interest recently, notably by New World Power Technology Company, Zond

Get Started

Introduction to wind turbine brakes

Jan 10, 2012 · Slowing and halting an 80-m-turbine rotor involves converting its kinetic energy into heat. Of course, there are several design decisions here.

Get Started

(PDF) Emergency braking system for the wind

Jan 1, 2016 · The need for an emergency braking system for the wind turbine is discussed in this paper. This system should be installed as the addition to a

Get Started

WE9465 P1955C TurbBrk Reprint v1 dd

Apr 24, 2015 · Wind-turbine engineers agree that a mechanical disc brake is the best solution in terms of reliability, simplicity of manufacture, ease of servicing and initial cost.

Get Started

What Does The Brake Do In A Wind Turbine? Maximizing

May 15, 2025 · The wind turbine industry has been growing rapidly over the past few decades, driven by the increasing demand for renewable energy sources. Wind turbines are an

Get Started

6 FAQs about [Wind turbine mechanical brake system]

What are the types of braking systems in wind turbines?

Types of Braking Systems in Wind Turbines These turbines have a sophisticated braking mechanism to regulate and control the immense forces. This system comprises blade pitch control mechanisms, yaw control brakes, and rotor brakes, all critical to the turbine’s functioning and safety. Rotor Brakes

How does a wind turbine brake work?

Similar to electrodynamic braking, electromagnetic braking generates a significant amount of heat, which can lead to generator overheating and damage (Rajambal et al., 2005). wind turbine's mechanical brake relies on a friction force exerted on a disc located on either the low-speed or high-speed shaft of the rotor.

Does a wind turbine need a braking system?

The international standard IEC 61400-1 stipulates that a wind turbine must have at least one aerodynamic braking system that acts directly on the rotor. If this requirement is not met, the braking system must apply force to the rotor shaft or rotor itself.

What braking method is used in a wind turbine rotor?

Su ch braking method enables to brake the wind turbine rotor within the necessary rotation frequency ranges. However, a of the wind wheel is generated into the heat energy on the generator windings . As a result, this method can be used only for a short period. 3. Airbraking.

What are rotor brakes?

Rotor brakes are mechanical systems designed to slow down or stop the rotation of the wind turbine’s rotor blades. This is crucial for maintenance, emergency stops, and to prevent damage during excessively high winds. There are two primary types of rotor brakes: Mechanical brakes use callipers and discs to create friction and slow a rotor’s motion.

What is a wind turbine yaw brake?

A wind turbine yaw brake is located on the yaw-system. It smoothly controls and positions the nacelle as it rotates with the wind to maximise power. The rotor brake can be mounted on the rotor (low-speed shaft) or generator (high-speed shaft). Used for parking and emergency stop operations.

Related Articles

-

Wind turbine PLC main system control

Wind turbine PLC main system control

-

Wind turbine 12v directly connected to inverter

Wind turbine 12v directly connected to inverter

-

Constant frequency system and wind turbine

Constant frequency system and wind turbine

-

Wind turbine AC system

Wind turbine AC system

-

Phase change cooling system for wind turbine

Phase change cooling system for wind turbine

-

Grid-connected wind turbine control system

Grid-connected wind turbine control system

-

Vertical Axis Wind Turbine Power System

Vertical Axis Wind Turbine Power System

-

Wind turbine automation system

Wind turbine automation system

-

5kw wind turbine grid-connected inverter

5kw wind turbine grid-connected inverter

-

What are the environmental protection works of wind and solar complementary communication base stations

What are the environmental protection works of wind and solar complementary communication base stations

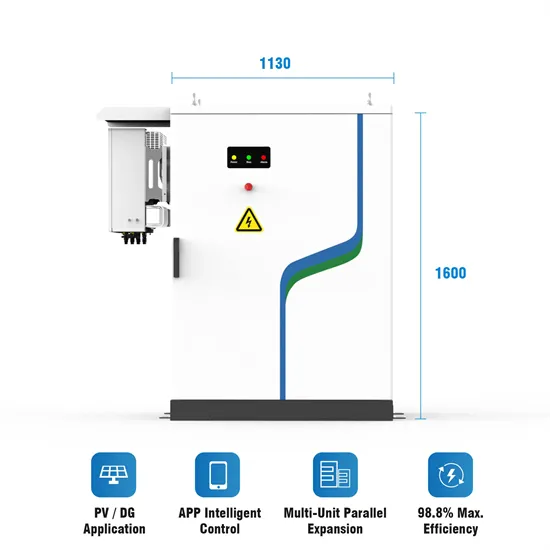

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.