PV Module Manufacturing Equipment Market

Feb 9, 2025 · Module production costs fell to $0.13/W in 2023, down 18% from 2020 levels, with equipment advancements contributing 35% of these savings through improved throughput and

Get Started

NPC incorporated | Global leader of solar

4 days ago · 1. High technology accumulated in PV industry and ability of applying it to new industries We have accumulated high technology in PV industry from

Get Started

COST BREAKDOWN OF A SOLAR PANEL FROM

Solar panel production cost Many NREL manufacturing cost analyses use a bottom-up modeling approach. The costs of materials, equipment, facilities, energy, and labor associated with each

Get Started

Solar Module Assembly Machine Manufacturers & Suppliers

Photovoltaic module production equipment manufacturer / supplier in China, offering High Performance Hydraulic Riveting Angle Framing Machine, Solar Simulator: Auto Long Pulse

Get Started

How much does the photovoltaic panel production line equipment cost

Investing in a photovoltaic panel production line is a complex and high cost decision, with equipment prices varying due to multiple factors, typically ranging from tens of millions to

Get Started

Looking for Solar Panel Production Line?

Feb 17, 2022 · Ooitech, Full Automatic solar panel manufacturing equipment supplier, producing solar panel Making Machines and production lines at

Get Started

Solar Panel Manufacturing Plant Setup Cost

IMARC Group''s report on solar panel manufacturing plant project provides detailed insights into business plan, setup, cost and requirements.

Get Started

Solar PV Module Manufacturing Cost Analysis | Case Study

According to an IMARC study, the global solar PV module market size reached 1,386.1 TWh in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 14.36%

Get Started

Specialist In Solar Panel Production Line

A Chinese High-Tech Company For Solar Panel Production Equipment&Turnkey Solution. Radiant PV Solar focus on manufacturing solar panel production line

Get Started

Solar PV Module Manufacturing Cost Analysis

Case study on solar PV module manufacturing cost: A comprehensive financial model for the plant''s setup, manufacturing, machinery and operations.

Get Started

Solar Panel Manufacturing Plant Costs: 6 Crucial Insights

Feb 2, 2023 · In this article, we will give details of the following costs: Machinery costs for solar panel manufacturing equipment (investment) Costs of building for your solar module

Get Started

Specialist in Solar Panel Manufacturing Equipment | Horad

Jan 16, 2025 · Turnkey Solutions for PV Modules Manufacturing We offer complete solar panel production lines for global customers to manufacture photovoltaic modules based on their

Get Started

Aug 14, 2024 · Ooitech, Full Automatic solar panel manufacturing equipment supplier, producing solar panel Making Machines and production lines at Good prices, including Assembly and

Get Started

Solar Manufacturing Cost Analysis | Solar Market

Aug 7, 2025 · Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers. This

Get Started

Photovoltaic panel assembly production

Needed for Solar Panel Production; Cost Solar Photovoltaic Panel Production Line is a high-tech manufacturing process that converts sunlight into electricity using photovoltaic cells,

Get Started

Solar Panel Manufacturing Unit

Find here Solar Panel Manufacturing Unit, Solar Panel Manufacturing Plant manufacturers, suppliers & exporters in India. Get contact details & address of

Get Started

300MW Turnkey Line | PV Production Line | Horad

Jan 16, 2025 · A 300MW solar module line is an automatic production line of solar modules. All of the individual equipment has high automation, lowering

Get Started

Complete turnkey lines for pv panel production

5 days ago · As a European technology leader, Ecoprogetti Srl supplies highly efficient equipment for the photovoltaic industry since 1998. The product range

Get Started

Photovoltaic Module Manufacturing Equipment

Oct 28, 2016 · PHOTOVOLTAIC MODULE EQUIPMENT: THE ECOPROGETTI SRL PROJECTS Generally speaking, photovoltaic modules are produced by the use of automated equipment,

Get Started

Edobo solar Photovoltaic (PV) production equipment

Online shopping for PV production equipment at the right price. Find out what''s hot and new from our online store. It''s Safe Payment and Worldwide Shipping.

Get Started

Photovoltaic module production equipment Manufacturer, photovoltaic

Photovoltaic module production equipment Supplier, photovoltaic module production equipment, Solar Panel Making Machine Manufacturers/ Suppliers - YiLi Pv Tech Factory Ltd

Get Started

Solar Panel Production Line Provider

Aug 15, 2025 · Full Processes of Solar Panel Manufacturing Our turnkey PV module production lines are designed to reduce your footprints, with

Get Started

How to Start a Solar Panel Manufacturing Plant:

To put it simply, a solar panel manufacturing plant is a facility where photovoltaic cells are produced and assembled into solar panels. These panels convert

Get Started

Price list of photovoltaic panel frame assembly machines

Nov 30, 2023 · China Solar Panel Framing Machine wholesale - Select 2024 high quality Solar Panel Framing Machine products in best price from certified Chinese Machine For Metal

Get Started

The Role of Machinery in PV Production | Eco

In this article, we''ll explore the key machines driving PV module production, their roles in the process, and how they are shaping trends in the solar industry.

Get Started

Solar Panel Production Machine

China Solar Panel Production Machine wholesale - Select 2025 high quality Solar Panel Production Machine products in best price from certified Chinese manufacturers, suppliers,

Get Started

6 key factors for choosing equipment in an efficient photovoltaic

Jul 7, 2025 · Discover 6 key factors to choose the right equipment for your photovoltaic production line and improve quality, efficiency, and OPEX.

Get Started

Photovoltaic panel assembly cost

Ooitech, Full Automatic solar panel manufacturing equipment supplier, producing solar panel Making Machines and production lines at Good prices, including Assembly and Turnkey Lines,

Get Started

Photovoltaic Cell Manufacturing Plant Report

The photovoltaic cell manufacturing plant project provides detailed insights into business plan, unit setup, cost, machinery and raw material requirements.

Get Started

Solar Manufacturing Cost Analysis | Solar Market

Aug 7, 2025 · NREL researchers consider the full production processes of solar cells and modules when conducting bottom-up cost modeling. Historical and

Get Started

6 FAQs about [Price of photovoltaic panel assembly production equipment]

How did our solar PV module manufacturing plant's financial model work?

Our solar PV module manufacturing plant's financial model was meticulously modelled to satisfy the client's requirements. It provided a thorough analysis of production costs including capital expenditures, manufacturing processes, raw materials, and operating costs.

What is the global solar PV module market size?

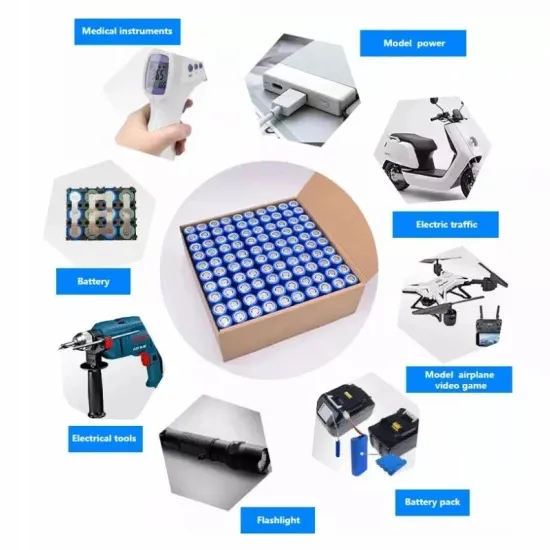

According to an IMARC study, the global solar PV module market size reached 1,386.1 TWh in 2024. Looking ahead, the market is expected to grow at a CAGR of approximately 14.36% from 2025 to 2033, reaching a projected capacity of 4,919.2 TWh by 2033. A number of important factors are driving the market for solar PV modules.

How are PV production costs modeled?

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers.

What is the production capacity of solar PV module?

The proposed facility is designed with an annual production capacity of 1,000 MW (1 GW) of solar PV module. Manufacturing Process: The first step in the production of solar PV modules is the melting and solidification of high-purity silicon pieces into polycrystalline ingots.

What are polycrystalline solar photovoltaic (PV) modules?

Polycrystalline solar photovoltaic (PV) modules are a key component of solar energy systems, harnessing sunlight and converting it into electricity through the photovoltaic effect. These modules are composed of multiple interconnected solar cells, each made from polycrystalline silicon.

What are the raw materials required for solar PV module manufacturing?

Raw Material Required: The primary raw materials utilized in the solar PV module manufacturing plant include solar cells, tempered glass, aluminium frame, encapsulant (EVA), and wiring and junction box. Techno-Commercial Parameter:

Related Articles

-

Chad photovoltaic panel production equipment price

Chad photovoltaic panel production equipment price

-

Buy Solar Photovoltaic Panel Production Equipment Ranking

Buy Solar Photovoltaic Panel Production Equipment Ranking

-

Apia Photovoltaic Panel Equipment Manufacturer

Apia Photovoltaic Panel Equipment Manufacturer

-

Cameroon portable photovoltaic panel BESS price

Cameroon portable photovoltaic panel BESS price

-

Slovakia photovoltaic panel BESS price

Slovakia photovoltaic panel BESS price

-

Democratic Republic of Congo photovoltaic panel assembly

Democratic Republic of Congo photovoltaic panel assembly

-

Bahrain BESS photovoltaic panel price latest

Bahrain BESS photovoltaic panel price latest

-

Solar energy production photovoltaic panel manufacturers

Solar energy production photovoltaic panel manufacturers

-

670W photovoltaic panel price

670W photovoltaic panel price

-

EK Electric Photovoltaic Panel Price

EK Electric Photovoltaic Panel Price

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

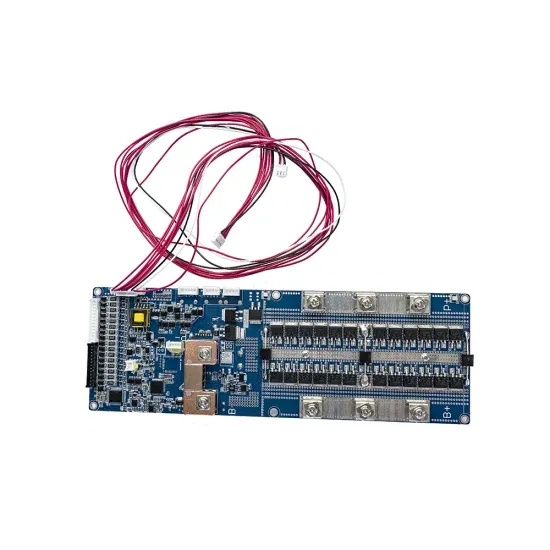

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.