A review of electrolyte additives and impurities in vanadium redox flow

Sep 1, 2018 · As one of the most important components of the vanadium redox flow battery (VRFB), the electrolyte can impose a significant impact on cell properties, performance and

Get Started

Milestone for vanadium flow battery technology

Sep 16, 2024 · Significant milestone claimed as tests validate first use of vanadium electrolyte produced at Perth facility in a functioning battery.

Get Started

Chemical Hazard Assessment of Vanadium–Vanadium Flow Battery

Jun 11, 2025 · This study aims to assess the chemical hazards of the electrolytes in vanadium–vanadium flow battery during failure mode. There is little or no chemical hazard

Get Started

Chemical Hazard Assessment of Vanadium–Vanadium Flow Battery

Jun 11, 2025 · The growing demand for energy storage and the rising frequency of lithium ion battery failure events worldwide underscore the urgency of addressing the battery safety

Get Started

Review—Preparation and modification of all-vanadium redox flow battery

Nov 21, 2024 · As a large-scale energy storage battery, the all-vanadium redox flow battery (VRFB) holds great significance for green energy storage. The electrolyte, a crucial

Get Started

Recent research on vanadium redox batteries: A

Mar 25, 2024 · Recent research on vanadium redox flow batteries: A review on electrolyte preparation, mass transfer and charge transfer for electrolyte

Get Started

A review of vanadium electrolytes for vanadium redox flow batteries

Mar 1, 2017 · There is increasing interest in vanadium redox flow batteries (VRFBs) for large scale-energy storage systems. Vanadium electrolytes which function as both the electrolyte

Get Started

Electrolytes for vanadium redox flow batteries

May 19, 2014 · Vanadium redox flow batteries (VRBs) are one of the most practical candidates for large-scale energy storage. Its electrolyte as one key component can intensively influence its

Get Started

Sustainable recycling and regeneration of redox flow battery

Feb 1, 2025 · As the demand for large-scale sustainable energy storage grows, redox flow batteries (RFBs), particularly all-vanadium RFBs (VRFBs), have emerged as a promising

Get Started

Recent Advances and Perspectives of Impurity

Nov 6, 2024 · The vanadium redox flow battery (VRFB) is an efficient electrochemical energy storage system, characterized by its energy efficiency,

Get Started

Preparation of vanadium flow battery electrolytes: in-depth

Jul 10, 2025 · Future research should focus on the direct utilization of vanadium leaching solutions, develop short-process novel technologies, and prioritize breakthroughs in key areas

Get Started

(PDF) Preparation of Electrolyte for Vanadium

Aug 7, 2020 · The vanadium redox‐flow battery is a promising technology for stationary energy storage. A reduction in system costs is essential for

Get Started

Global electrolyte standard ''crucial for scalability

Mar 11, 2025 · Global standards and specifications for the electrolyte used in vanadium redox flow batteries are "crucial" for the technology''s prospects.

Get Started

Vanadium Redox-Flow-Battery Electrolyte Preparation with

May 3, 2013 · A waste-free method was developed to prepare electrolytes using reducing agents for vanadium redox flow battery. Via this approach, both the electrolyte cost and waste can be

Get Started

Vanadium Flow Battery for Energy Storage:

Mar 28, 2013 · The vanadium flow battery (VFB) as one kind of energy storage technique that has enormous impact on the stabilization and smooth output of

Get Started

Vanadium Electrolyte Studies for the Vanadium

Jun 13, 2016 · The electrolyte is one of the most important components of the vanadium redox flow battery and its properties will affect cell performance and

Get Started

Accelerated design of vanadium redox flow

Feb 24, 2021 · This bi-additive-based electrolyte yields a more than 180% and more than 30% enhancement of thermal stability and energy density,

Get Started

Synthesis of a Low-Cost V3.5+ Electrolyte for

Dec 15, 2022 · In this study, a cost-effective method for preparing a V3.5+ electrolyte for a vanadium redox flow battery (VRFB) was developed using the

Get Started

Advanced Electrolyte Formula for Robust

Jan 24, 2024 · A novel approach to designing electrolyte additive significantly increases the overall performance and of the all-vanadium redox flow battery.

Get Started

Preparation of Electrolyte for Vanadium

19 rows · Jul 21, 2020 · An interesting technology for energy storage is the vanadium redox-flow battery (VRFB), which uses four stable oxidation stages

Get Started

Novel electrolyte design for high-efficiency vanadium redox flow

Jul 15, 2025 · Abstract Vanadium redox flow batteries (VRFB) are gradually becoming an important support to address the serious limitations of renewable energy development. The

Get Started

Catalytic production of impurity-free V3.5+ electrolyte for vanadium

Sep 27, 2019 · In this work, we present a simpler method for chemical production of impurity-free V 3.5+ electrolyte by utilizing formic acid as a reducing agent and Pt/C as a catalyst. With the

Get Started

Flow batteries, the forgotten energy storage device

Jan 21, 2025 · In standard flow batteries, two liquid electrolytes—typically containing metals such as vanadium or iron—undergo electrochemical

Get Started

Research progress in preparation of electrolyte for all-vanadium

Feb 25, 2023 · All-vanadium redox flow battery (VRFB), as a large energy storage battery, has aroused great concern of scholars at home and abroad. The electrolyte, as the active material

Get Started

Iron-vanadium redox flow batteries electrolytes: performance

Nov 10, 2024 · This approach greatly enhances the conductivity and diffusion coefficient of the electrolyte, resulting in a novel, cost-effective, and highly efficient electrolyte for iron-vanadium

Get Started

Effect of Inorganic Additive Strategy on the

Oct 15, 2024 · Inorganic ions are considered to be effective additives to improve the temperature stability of all-vanadium redox flow batteries. In this study,

Get Started

Preparation of Vanadium (3.5+) Electrolyte by

Nov 8, 2024 · In this study, vanadium (3.5+) electrolyte was prepared for vanadium redox flow batteries (VRFBs) through a reduction reaction using a

Get Started

Electrolyte engineering for efficient and stable vanadium redox flow

May 1, 2024 · This paper provides a review of electrolyte properties, supporting electrolytes, electrolyte additives, synthesis methods, and their impact on battery performance. Moreover,

Get Started

Preparation of vanadium flow battery electrolytes: in-depth

Jul 10, 2025 · The preparation technology for vanadium flow battery (VRFB) electrolytes directly impacts their energy storage performance and economic viability. This review analyzes

Get Started

U.S. Vanadium Launches North America''s

5 days ago · US Vanadium has completed a $2 million expansion of its capacity to produce ultra-high-purity electrolyte used by Vanadium Redox Flow

Get Started

Vanadium Flow Battery: How It Works and Its Role in Energy

Mar 3, 2025 · A vanadium flow battery works by circulating two liquid electrolytes, the anolyte and catholyte, containing vanadium ions. During the charging process, an ion exchange happens

Get Started

U.S. Vanadium Successfully Recycles Electrolyte

6 days ago · U.S. Vanadium Successfully Recycles Electrolyte From a Decommissioned Vanadium Redox Flow Battery at a 97% Recovery Rate

Get Started

Adjustment of Electrolyte Composition for

Oct 16, 2023 · All-vanadium FB (VFB) is one of the flow-battery technologies, which is the most investigated and is already commercialized. However, the

Get Started

Adjustment of Electrolyte Composition for

Oct 16, 2023 · Commercial electrolyte for vanadium flow batteries is modified by dilution with sulfuric and phosphoric acid so that series of electrolytes with

Get Started

A comprehensive review of advancements in vanadium electrolyte

Vanadium Redox Flow Batteries (VRFBs) have broad application prospects in the field of electrochemical energy storage due to their long cycle life, intrinsic safety and free scalability.

Get Started

6 FAQs about [Vanadium flow battery electrolyte]

What is a Commercial electrolyte for vanadium flow batteries?

Commercial electrolyte for vanadium flow batteries is modified by dilution with sulfuric and phosphoric acid so that series of electrolytes with total vanadium, total sulfate, and phosphate concentrations in the range from 1.4 to 1.7 m, 3.8 to 4.7 m, and 0.05 to 0.1 m, respectively, are prepared.

What are vanadium redox flow batteries?

There is increasing interest in vanadium redox flow batteries (VRFBs) for large scale-energy storage systems. Vanadium electrolytes which function as both the electrolyte and active material are highly important in terms of cost and performance.

Why is vanadium electrolyte important?

Vanadium electrolyte, one of the key components of the VRFB system, plays a crucial role in determining the cost and performance of the battery, which are important factors in moving the VRFB towards greater reliability, economy, and market value.

How can vanadium electrolyte improve battery performance?

The performance of vanadium electrolyte can be enhanced by suitable trace additives, which extend the life cycle of the battery and reduce the frequency of replacement. These additives favor green development and cost-saving while having no significant impact on post-recycling.

How does vanadium ions affect battery stability and energy storage?

The result is that the concentration of vanadium ions in the electrolyte is usually lower than 2 mol/L, which seriously affects battery stability and energy storage .

What is a commercial vanadium electrolyte?

Currently, commercial vanadium electrolytes are primarily H 2 SO 4 (2.5–3.5 mol/L) solutions dissolving 1.5–2 mol/L vanadium, with energy densities typically around 25 Wh/L, significantly lower than Zn mixed flow batteries, which can achieve energy densities up to 70 Wh/L [10, 20].

Related Articles

-

Vanadium full liquid flow battery energy storage project

Vanadium full liquid flow battery energy storage project

-

Rwanda Vanadium Flow Battery Project

Rwanda Vanadium Flow Battery Project

-

Field capacity of vanadium liquid flow battery

Field capacity of vanadium liquid flow battery

-

The world s largest vanadium flow battery

The world s largest vanadium flow battery

-

Belmopan s new all-vanadium flow battery electrolyte pump

Belmopan s new all-vanadium flow battery electrolyte pump

-

Timor-Leste Vanadium Flow Battery

Timor-Leste Vanadium Flow Battery

-

Iron-zinc flow battery electrolyte

Iron-zinc flow battery electrolyte

-

Monaco Vanadium Liquid Flow Energy Storage Battery

Monaco Vanadium Liquid Flow Energy Storage Battery

-

How much vanadium does a 1mw all-vanadium liquid flow battery use

How much vanadium does a 1mw all-vanadium liquid flow battery use

-

Namibia Electric Vanadium Flow Battery

Namibia Electric Vanadium Flow Battery

Commercial & Industrial Solar Storage Market Growth

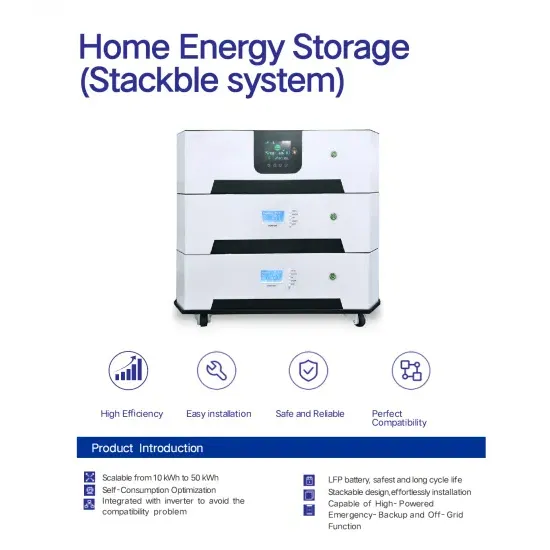

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.