Inverter Specifications and Data Sheet

Dec 18, 2024 · The maximum input voltage to the inverter is an important specification to ensure that the equipment operates within safe limits. For 12V

Get Started

How Much Power Does An Inverter Draw With

Nov 17, 2023 · Note: Figures mentioned above are subject to change. Check the technical specification section of the inverter model. Here is a table of

Get Started

Inverters 101: Understanding amps and volts

Jun 7, 2018 · Here''s a diagram with a 12-volt battery, an inverter and a 1,200-watt microwave oven. Note that on the 12-volt side of the inverter you need 1,200

Get Started

Correct inverter size

Dec 31, 2022 · Between the battery and the inverter. Inverters can draw a lot of current called amperes or amps for short. To figure out amps you divide the

Get Started

What Is Inverter Voltage?

This guide explains the different types of inverter voltages and how to choose the right one for your home. Inverter voltage plays a vital role in determining the efficiency and compatibility of

Get Started

Inverter AC to DC Amperage Conversion

Feb 24, 2025 · AC to DC Conversion Calculator The first step to sizing a battery pack when using a DC to AC power inverter is to know your DC amp rating.

Get Started

Inverter Amps: The Ultimate Guide to Understanding Power

Jan 29, 2025 · When it comes to powering your devices on the go, inverters are an excellent solution. However, it''s essential to understand how much power they consume to ensure safe

Get Started

How To Size An Inverter for Solar and Off Grid

Nov 9, 2022 · A solar inverter is an often overlooked but critical aspect of a home solar system. The inverter is responsible for converting the DC power

Get Started

CSM_Inverter_TG_E_1_1

Mar 27, 2016 · The inverter first converts the input AC power to DC power and again creates AC power from the converted DC power using PWM control. The inverter outputs a pulsed

Get Started

How much power does an inverter draw?

Looking for an inverter calculator? Learn how to determine the 300, 1200, 1500 & 2000 watt inverter amp draw in our Inverter FAQs section. Read now.

Get Started

How Many Amps Does an Inverter Draw?

Apr 7, 2025 · Current draw calculations for 300W to 5000W inverters in 12V, 24V and 48V systems, and common myths and questions about inverter current draw.

Get Started

Inverter Power Calculator & Formula Online Calculator Ultra

Oct 3, 2024 · High-efficiency inverters waste less power as heat and are more economical to use. How does rated power affect inverter selection? The rated power determines the maximum

Get Started

Understanding Inverter Voltage: Definition,

Dec 16, 2024 · Inverter voltage is a voltage generated by the inverter after several electrons that converts a series of direct current (DC) into alternating current

Get Started

How Many Amps Does a 1000 Watt Power Inverter Draw?

May 21, 2024 · Understanding how many amps a 1000 watt inverter draws is crucial for designing and maintaining efficient power systems. By considering factors like efficiency, input voltage,

Get Started

How many volts is suitable for solar inverter

Jul 31, 2024 · To determine the appropriate voltage for a solar inverter, one must consider several factors that directly influence the inverter''s performance and

Get Started

How many V does the solar inverter have? | NenPower

Mar 3, 2024 · 1. The number of Volts (V) in a solar inverter varies widely depending on the specific model and application, generally ranging from 12V to 1500V, with most residential models

Get Started

Frequently Asked Questions About Power Inverters

Power Inverter FAQ Frequently Asked Questions about Power Inverters What does a power inverter do, and what can I use one for? Using an inverter for basic emergency home backup

Get Started

How To Wire Solar Panels In Series Vs. Parallel

To accommodate more panels in the future, you should have an oversized inverter. Does the use of microinverters or optimizers change how solar panels are wired? The use of microinverters

Get Started

How many amps does a 1000 watt inverter

Sep 23, 2023 · How many amps does a 1000 watt inverter draw? The maximum amount of Current (Amps) that a 1000 Watt inverter draws will mainly depend

Get Started

Solar Power Basics for Beginners: Volts, Amps,

Peak/surge power output - The max amount of watts the solar inverter can produce for a few seconds to support the high startup power some electronics

Get Started

Calculate Battery Size For Any Size Inverter

Mar 3, 2023 · So I have made it easy for you, use the calculator below to calculate the battery size for 200 watt, 300 watt, 500 watt, 1000 watt, 2000

Get Started

Understanding Solar Panel Voltage: A

Jul 14, 2023 · Solar panels generate DC power, which is converted to AC power using an inverter for compatibility with home systems. How much voltage does

Get Started

How Many Amps Does a 100, 300, 500, 600, 750,

Jun 20, 2023 · A 300 Watt Inverter generally pulls about 29.4 Amps. A 500 Watt Inverter usually draws approximately 52 Amps. A 600 Watt Inverter commonly

Get Started

Inverter Battery Voltage: How Many Volts Are Needed For

Mar 27, 2025 · An inverter battery typically operates at 12V, 24V, or 48V. These voltages represent the nominal direct current (DC) needed for the inverter''s function.

Get Started

Inverters 101: Understanding amps and volts

Jun 7, 2018 · When we want to use it for a 120-volt appliance like our microwave to coffee maker, we convert it from 12 volts up to 120 volts. For now at least

Get Started

Understanding inverter voltage

Jan 10, 2024 · In this article, let''s embark on a comprehensive journey to unravel the mysteries surrounding inverter voltage, exploring its nuances, applications,

Get Started

Understanding inverter voltage

Jan 10, 2024 · Inverter voltage typically falls into three main categories: 12V, 24V, and 48V. These values signify the nominal direct current (DC) input voltage required for the inverter to function

Get Started

How many volts does the energy storage

Apr 14, 2024 · How many volts does the energy storage inverter have? 1. Energy storage inverters typically operate within a range of voltages, commonly

Get Started

How many Watts @ 12v to provide 600 watts @240v Via Inverter

Jul 18, 2009 · Watts will be the same apart from inverter loses. It is the current that will change. 600 watts at 12v is 50amps but with inverter efficiency it will be 55 amps. 600 watts at 240v is

Get Started

Frequently Asked Questions

Frequency converters that are easy to upgrade also improve productivity. A networked PLC, for example, can remotely update inverter firmware and application data through a single machine

Get Started

The Only Inverter Size Chart You''ll Ever Need

Sep 25, 2023 · We have created a comprehensive inverter size chart to help you select the correct inverter to power your appliances.

Get Started

6 FAQs about [How many volts does the inverter change]

What voltage does an inverter use?

In different countries, the applicable AC voltage is different, and most countries use 110v, 120v output inverter voltage. You can confirm on the search engine or see how much AC voltage the home appliance label uses. How can the quality of inverter output voltage be measured?

What is a start inverter voltage?

The start inverter voltage is the minimum input voltage required for the inverter to initiate the conversion process. In the case of a 12V inverter, the start inverter voltage is typically around 9.5VDC. This threshold ensures that the inverter can begin its operation reliably without placing undue stress on the connected battery.

What is the start voltage of a 12V inverter?

In the case of a 12V inverter, the start inverter voltage is typically around 9.5VDC. This threshold ensures that the inverter can begin its operation reliably without placing undue stress on the connected battery. What is cut off voltage in inverter?

Why is inverter voltage important?

In the realm of power electronics, the inverter voltage is a critical parameter that dictates its performance, compatibility, and safety. Understanding the intricacies of inverter voltage is essential for anyone seeking a reliable and efficient power supply.

What happens if inverter voltage is low?

Operating an inverter with consistently low input inverter voltage can lead to inefficiencies, overheating, and potential damage. Maintaining the input voltage within the specified range is essential for the optimal performance and longevity of the inverter.

What is the maximum input voltage for a 12V inverter?

The maximum input voltage for an inverter is a critical specification that ensures the device operates within safe limits. For a 12V inverter, the maximum input inverter voltage is typically around 16VDC. This safety margin provides a buffer to accommodate fluctuations in the power source and protect the inverter from potential damage.

Related Articles

-

How many volts does a 48v inverter change to

How many volts does a 48v inverter change to

-

How many volts does the minimum inverter change

How many volts does the minimum inverter change

-

How many volts should a home inverter use

How many volts should a home inverter use

-

How many volts does the photovoltaic inverter have

How many volts does the photovoltaic inverter have

-

How many volts does a 12v inverter boost

How many volts does a 12v inverter boost

-

How many watts is a 500w solar light equivalent to 220 volts

How many watts is a 500w solar light equivalent to 220 volts

-

How many kilowatt-hours of electricity does a 24v inverter generate

How many kilowatt-hours of electricity does a 24v inverter generate

-

How much voltage does a normal inverter generate

How much voltage does a normal inverter generate

-

How many volts does each cell of a 660w photovoltaic module have

How many volts does each cell of a 660w photovoltaic module have

-

How to check the inverter of local communication base station

How to check the inverter of local communication base station

Commercial & Industrial Solar Storage Market Growth

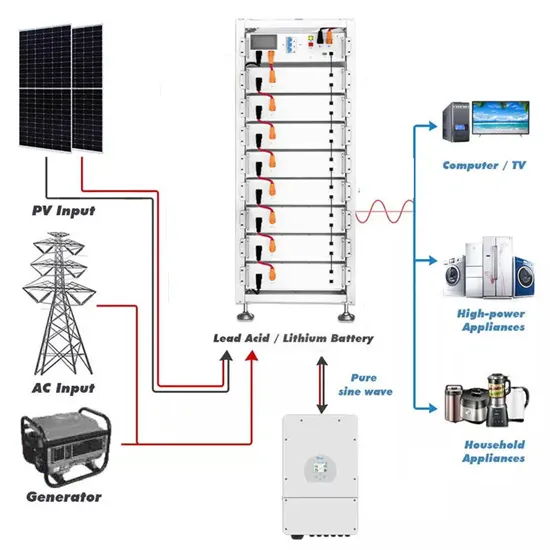

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.