Low Voltage, Low Power, Inverter-Based Switched-Capacitor

An operational transconductance amplifier (OTA) is a major building block and consumes most of the power in switched-capacitor (SC) circuits, but it is difficult to design low-voltage OTAs in

Get Started

Low-Power IC Design: Techniques and Best

May 16, 2023 · To create a low-power design, the designer must reduce every individual component of power that is contributing to the overall power

Get Started

Inverter-based low-power delta–sigma modulator using

Feb 17, 2021 · A low-power delta–sigma modulator based on inverter operational-transconductance amplifiers (OTAs) using correlated level shifting technique (CLS) is

Get Started

Analysis and Design of Low Voltage Low Power Inverter

Aug 13, 2017 · In this paper, an approach of double tail comparator with a technique of regenerative inverter is introduce which is importantly basic component of ADCs, the result is

Get Started

Analysis and Design of a Low-Voltage Low-Power

May 8, 2023 · Abstract— The need for ultra low-power, area efficient, and high speed analog-to-digital converters is pushing toward the use of dynamic regenerative comparators to maximize

Get Started

How to make Simple Low power Inverter circuit

May 11, 2021 · In this Tutorial we will learn about how to make simple DC to AC low power inverter. The working principle, Inverter circuit designing for Low power inverter and

Get Started

Performance Evaluation and Design of a Low Voltage

Feb 24, 2017 · Proposed inverter gives less power disseminating less delay than customary inverter. New proposed arrange gives 25% reduction in power diminishment and 75%

Get Started

Analysis and Design of Low Voltage Low Power Inverter

Download Citation | On Aug 1, 2017, Shweta Srivastava and others published Analysis and Design of Low Voltage Low Power Inverter Based Double Tail Comparator | Find, read and

Get Started

untitled [xilirprojects ]

Jan 21, 2023 · Analysis and Design of a Low-Voltage Low-Power Double-Tail Comparator Samaneh Babayan-Mashhadi, Student Member, IEEE, and Reza Lotfi, Member, IEEE

Get Started

Low Voltage Inverter: Definition, Function, And Applications

3 days ago · This article will discuss the definition, function, and applications of low voltage inverters, especially in renewable energy systems such as solar power.

Get Started

Design Strategies for Ultra-Low Voltage Circuits

Sep 10, 2019 · This paper reviews our recent progress in mapping out the low energy design space including the presence of an energy-optimal supply voltage, and also touches on gate

Get Started

Analysis and Design of a Low-Voltage Low

Feb 11, 2013 · The need for ultra low-power, area efficient, and high speed analog-to-digital converters is pushing toward the use of dynamic regenerative

Get Started

A modular design approach for cost-optimised

To meet demanding cost constraints, inverters based on low voltage systems often adopt Brushless DC (BLDC) motors controlled with a six-step

Get Started

A novel low power and highly efficient inverter design

Sep 5, 2020 · In this paper an entirely new approach is presented to address this problem. The proposed circuit dissipates least power as compared to other power saving logic styles. A

Get Started

Design and Optimization of Low-Power CMOS Inverter

Aug 13, 2024 · The design of low-power CMOS inverters involves various techniques such as transistor sizing, voltage scaling, and circuit optimization to minimize power consumption.

Get Started

On the design of an ultra-low-power ultra-low-voltage inverter

Apr 1, 2024 · In this paper, an inverter-based Operational Transconductance Amplifier (OTA) is introduced. This design is tailored for applications demanding ultra-low power consumption

Get Started

How to Design a Compact Low-voltage BLDC Motor

Oct 30, 2022 · the design are threaded mounting posts for attaching a heats nk to increase the power throughput. Detailed steps to attaching a heatsink are explained in [1]. The drive is

Get Started

Inverter Based Comparator Design for Low Voltage Inputs

Dec 27, 2017 · In design of ADCs, comparators of high speed, low power consumption are used. Comparator in ultra deep sub micrometer (UDSM) technologies suffers from low supply

Get Started

Understanding Low Frequency Power Inverters

6 days ago · The Understanding Low Frequency Power Inverters: A Comprehensive Guide is an in-depth resource for anyone interested in the design, construction, and operation of low

Get Started

Performance Evaluation and Design of a Low Voltage

Feb 24, 2017 · Performance Evaluation and Design of a Low Voltage Low Power Lector Inverter based Twofold Comparator Surendra Kumar1 Vimal Agarwal2 1M. Tech. Student 2Associate

Get Started

Low Voltage, Low Power, Inverter-Based Switched-Capacitor Delta

Jan 27, 2009 · An operational transconductance amplifier (OTA) is a major building block and consumes most of the power in switched-capacitor (SC) circuits, but it is difficult to design low

Get Started

Three-phase inverter reference design for 200-480VAC

May 11, 2022 · The power good pin of U6 is an open drain output which asserts low if output voltage is low due to thermal shutdown, dropout, over-voltage or EN shutdown. In this design

Get Started

Low Power Inverter

Dec 9, 2024 · ABSTRACT : This paper describes a low-power inverter circuit using the ULN2004 Darlington transistor array and the HCF4047 monostable/astable multivibrator IC. The main

Get Started

Designing 1kW Sine Wave Inverter Circuit

Aug 16, 2023 · The current depends on the load applied. There is no need to add a switch in the high-current path to make the inverter turn on and off. The

Get Started

Design of Low-Voltage Low-Power CMOS Delta

The second implementation is differential and operates with 900 mV. It achieves 77 dB dynamic range in 16 kHz bandwidth and consumes 40 &mgr;W. Design

Get Started

A High Performance Inverter Based Comparator Design

Jan 10, 2016 · The rapidly growing market of portable electronic systems such as wireless communication devices, consumer electronics or battery-powered medical devices increases

Get Started

Implementation on Low Power Design Using

Apr 27, 2024 · RELATED RESEARCH WORK To minimize the force utilization and enhance the execution grids of ADC, the scrutinizes essentially concentrate on the streamlining of the

Get Started

Tackling Low-Voltage Signaling in Inverter

Jan 1, 2025 · Discover practical strategies for managing noise in high-power inverter designs. From component selection and PCB stack-up to routing

Get Started

Electronics | Special Issue : Design of Low

Jul 15, 2025 · This paper presents an ultra-low-power, inverter-based, universal Gm-C filter capable of operating in multiple modes: voltage, current,

Get Started

Design of Low-Power Double Tail Dynamic Comparator

May 12, 2018 · Also, based on theoretical analyses, a new dynamic comparator with low-voltage low-power capability was proposed in order to improve the performance of the comparator.

Get Started

Electronics | Special Issue : Ultra-Low Power

Apr 30, 2021 · This paper proposes topological enhancements to increase voltage gain of ultra-low-voltage (ULV) inverter-based OTAs. The two proposed

Get Started

Electronics | Special Issue : Ultra-Low-Voltage

Jun 16, 2025 · Dear Colleagues, In the modern era of the interconnected world, ultra-low-voltage/power electronics is the true enabling factor for higher-impact

Get Started

Low Power Inverter

Dec 9, 2024 · This paper describes a low-power inverter circuit using the ULN2004 Darlington transistor array and the HCF4047 monostable/astable multivibrator IC. The main aim is to

Get Started

A modular design approach for cost-optimised

An inverter''s requirements clearly depend on the specific application; however, cost reduction is often the priority for low-voltage, low-power inverters. This

Get Started

Inverter Based Comparator Design for Low Voltage Inputs

Dec 27, 2017 · Now ADC requires lesser power dissipation, low noise, better slew rate, high speed etc. Dynamic comparator are being used in today''s A/D converters extensively because

Get Started

6 FAQs about [Low voltage and low power inverter design]

Can double tail comparator be used in regenerative inverter?

In this paper, an approach of double tail comparator with a technique of regenerative inverter is introduce which is importantly basic component of ADCs, the result is confirmed by the 180 nm CMOS Technology post layout simulation. The supply low voltage at 0.8V and sampling frequency GHz are taken under consideration.

Can adiabatic logic be used to implement low power circuits?

The technique can also be used to implement low power circuits using TFETs on lower supply voltages. Shinghal D, Saxena A, Noor A (2013) Adiabatic logic circuits: a retrospect. MIT Int J Electron Commun Eng 3 (2):108–114 Singh R, Mehra R (2013) Power efficient design of multiplexer using adiabatic logic. Int J Adv Eng Technol 6 (1):246

Which logic style dissipates least power?

The proposed circuit dissipates least power as compared to other power saving logic styles. A comparative analysis of all the three logic styles has been presented for better understanding. The circuits are implemented and simulated on Tanner V.13 using 90 nm technology.

Does a double tail dynamic comparator reduce the delay in low-voltage supplies?

the post-layout simulation results of the delay and the energy per conversion of the mentioned dynamic comparators versus supply voltage variation. As shown in Fig. 9(a), in comparison with the other two structures, the delay of the proposed double- tail dynamic comparator is significantly reduced in low-voltage supplies.

Why is CMOS preferred if power dissipation is low?

CMOS is preferred where least power dissipation is required. Although the power dissipation in CMOS is low compared to other logic families, it still dissipates a considerable amount of power during switching events in the form of heat. Voltage scaling is one of the solutions suggested to decrease the power dissipation of circuits.

What is a basic operational transconductance amplifier based on an inverter?

Inverter-based OTA A basic operational transconductance amplifier (OTA) based on an inverter, named OTA-A, is shown in Fig. 1. In a simple inverter consisting of NMOS and PMOS transistors, the aspect ratio of the PMOS transistors is typically chosen to be 4 times that of the NMOS transistors to compensate for the difference in charge mobility .

Related Articles

-

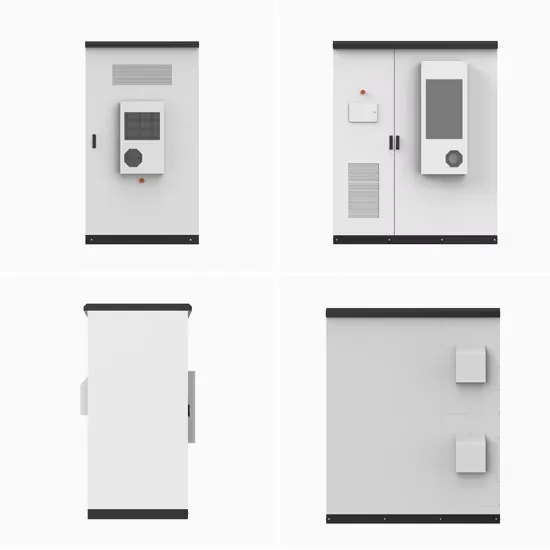

High voltage power station inverter

High voltage power station inverter

-

UPS uninterruptible power supply input voltage is low

UPS uninterruptible power supply input voltage is low

-

Doxin inverter voltage is low

Doxin inverter voltage is low

-

Bulgaria low voltage inverter price

Bulgaria low voltage inverter price

-

Low frequency inverter output power difference

Low frequency inverter output power difference

-

What is the voltage of a low voltage inverter

What is the voltage of a low voltage inverter

-

Base station power cabinet system voltage is too low

Base station power cabinet system voltage is too low

-

The inverter has low voltage when working for a long time

The inverter has low voltage when working for a long time

-

Production of 50W low power inverter

Production of 50W low power inverter

-

Palikir low power inverter price

Palikir low power inverter price

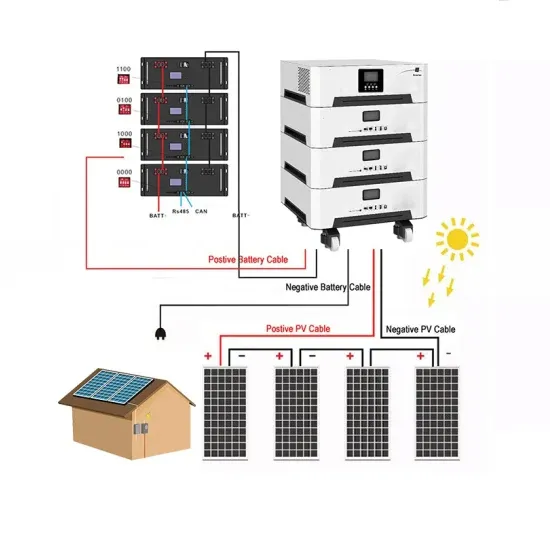

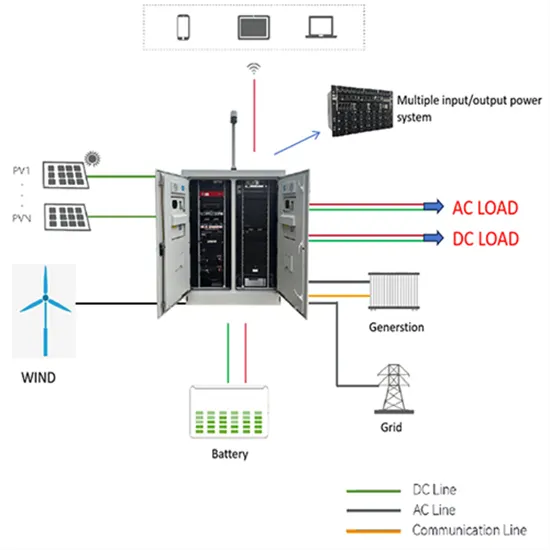

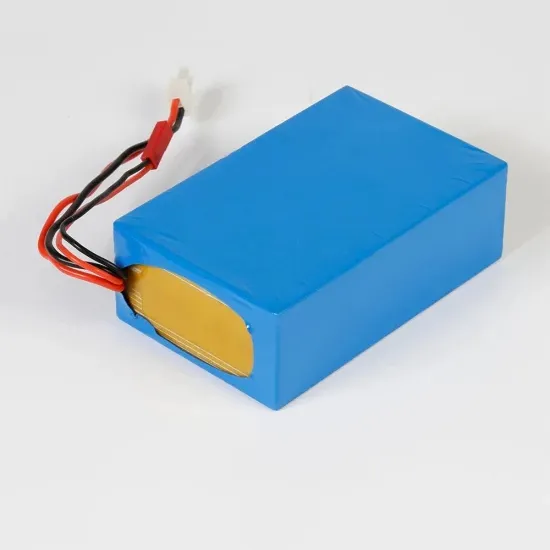

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.