Next-Generation Vanadium Flow Batteries

Jan 6, 2023 · Since the original all-vanadium flow battery (VFB) was proposed by UNSW in the mid-1980s, a number of new vanadium-based electrolyte chemistries have been investigated

Get Started

Attributes and performance analysis of all-vanadium redox flow battery

May 17, 2023 · Vanadium redox flow batteries (VRFBs) are the best choice for large-scale stationary energy storage because of its unique energy storage advantages. However, low

Get Started

Sumitomo Electric launches vanadium redox

Mar 3, 2025 · Japanese manufacturer Sumitomo Electric has released a new vanadium redox flow battery (VRFB) suitable for a variety of long-duration

Get Started

Belmopan s new all-vanadium flow battery electrolyte pump

Mar 25, 2021 · New operating strategy for all-vanadium redox flow batteries to mitigate electrolyte imbalance electrolytes were pumped from the reservoirs to the cell at a constant flow rate of

Get Started

Preparation of Electrolyte for Vanadium

Jul 21, 2020 · A vanadium redox-flow battery electrolyte with a concentration of 1.6 mol L−1 is produced by the dissolution of vanadium pentoxide and the

Get Started

Electrolytes for vanadium redox flow batteries

Mar 22, 2022 · Electrolytes for vanadium redox flow batteries Abstract: Vanadium redox flow batteries (VRBs) are one of the most practical candidates for large-scale energy storage. Its

Get Started

Research progress in preparation of electrolyte for all-vanadium

Feb 25, 2023 · All-vanadium redox flow battery (VRFB), as a large energy storage battery, has aroused great concern of scholars at home and abroad. The electrolyte, as the active material

Get Started

Vanadium electrolyte: the ''fuel'' for long-duration

May 22, 2023 · Samantha McGahan of Australian Vanadium on the electrolyte, which is the single most important material for making vanadium flow batteries.

Get Started

ALL-VANADIUM REDOX FLOW BATTERY

Nov 5, 2024 · The fluorine-free proton exchange membrane independently developed by CE, which is composed of hydrocarbon polymers, has excellent performance and can be used for

Get Started

Vanadium Flow Batteries Demystified

Nov 17, 2023 · And the electrolyte, which requires chemical processing With vanadium flow batteries, all parts and components have a recyclability factor

Get Started

Performance enhancement of vanadium redox flow battery by flow

Vanadium redox flow batteries (VRFBs) are one of the most promising energy storage devices, but they have not yet reached their viable pinnacle of performance and commercialization. A

Get Started

Design and development of large-scale vanadium redox flow batteries

Jan 30, 2024 · Vanadium redox flow battery (VRFB) energy storage systems have the advantages of flexible location, ensured safety, long durability, independent power and capacity

Get Started

New operating strategy for all-vanadium redox flow batteries

Apr 1, 2022 · In this study, we attempt to mitigate the degree of electrolyte imbalance by designing different initial supporting electrolyte concentrations between the anolyte and catholyte. The

Get Started

Vanadium Flow Battery: How It Works and Its Role in Energy

Mar 3, 2025 · A vanadium flow battery works by circulating two liquid electrolytes, the anolyte and catholyte, containing vanadium ions. During the charging process, an ion exchange happens

Get Started

Characteristics of a new all-vanadium redox flow battery

Jan 1, 2001 · The construction and performance of an all-vanadium redox flow system is described. The battery employs vanadyl sulphate in sulphuric acid solution as the electrolyte,

Get Started

Vanadium flow batteries at variable flow rates

Jan 1, 2022 · Vanadium flow batteries employ all-vanadium electrolytes that are stored in external tanks feeding stack cells through dedicated pumps. These batteries can possess near limitless

Get Started

Electrolytes for vanadium redox flow batteries

May 19, 2014 · Vanadium redox flow batteries (VRBs) are one of the most practical candidates for large-scale energy storage. Its electrolyte as one key component can intensively influence its

Get Started

A 3D modelling study on all vanadium redox flow battery at

Nov 1, 2023 · As a novel energy storage technology, flow batteries have received growing attentions due to their safety, sustainability, long-life circles and excellent stability. All

Get Started

Characteristics of a new all-vanadium redox flow battery

Jan 31, 2017 · The construction and performance of an all-vanadium redox flow system is described. The battery employs vanadyl sulphate in sulphuric acid solution as the electrolyte,

Get Started

Vanadium redox flow batteries: A comprehensive review

Oct 1, 2019 · Recirculation mode constantly pumps electrolyte through the battery which only requires two tanks, while batch mode is a four-tank system where the electrolytes move from

Get Started

A comparative study of iron-vanadium and all-vanadium flow battery

Feb 1, 2022 · The all-Vanadium flow battery (VFB), pioneered in 1980s by Skyllas-Kazacos and co-workers [8], [9], which employs vanadium as active substance in both negative and positive

Get Started

Vanadium redox flow batteries: Flow field design and flow

Jan 1, 2022 · • Systematic analyzes the attributes and performance metrics of the battery for evaluating the flow field performance of the vanadium redox flow battery. • Comparative study

Get Started

Performance enhancement of vanadium redox flow battery

Oct 10, 2024 · Electrolyte utilization and the consequent concentration polarization significantly limit the potential increase in power density and contribute to electrode degradation in

Get Started

Electrolyte engineering for efficient and stable vanadium redox flow

May 1, 2024 · When studying electrolyte flow rates, two points should be considered: low flow rates will be employed when investigating novel channel or electrode structures to assess their

Get Started

Fact Sheet: Vanadium Redox Flow Batteries (October 2012)

Dec 6, 2012 · Unlike other RFBs, vanadium redox flow batteries (VRBs) use only one element (vanadium) in both tanks, exploiting vanadium''s ability to exist in several states. By using one

Get Started

Sumitomo Electric Develops Advanced Vanadium Redox Flow Battery

Feb 26, 2025 · Sumitomo Electric is pleased to introduce its advanced vanadium redox flow battery (VRFB) at Energy Storage North America (ESNA), held at the San Diego Convention

Get Started

Development status, challenges, and perspectives of key

Dec 1, 2024 · Abstract All-vanadium redox flow batteries (VRFBs) have experienced rapid development and entered the commercialization stage in recent years due to the

Get Started

Polypropylene Immersion Pumps for Circulation

Read how we supplied 2 Polypropylene Vertical Immersion Pumps for a Vanadium Redox Flow Battery. The Pumps used were for the Circulation of

Get Started

Preparation of Electrolyte for Vanadium

Jul 21, 2020 · An interesting technology for energy storage is the vanadium redox-flow battery (VRFB), which uses four stable oxidation stages of

Get Started

Membranes for all vanadium redox flow batteries

Dec 1, 2020 · This review on the various approaches to prepare polymeric membranes for the application in Vanadium Redox Flow Batteries (VRB) reveals various factors which should be

Get Started

6 FAQs about [Belmopan s new all-vanadium flow battery electrolyte pump]

What is a vanadium flow battery?

Vanadium flow batteries employ all-vanadium electrolytes that are stored in external tanks feeding stack cells through dedicated pumps. These batteries can possess near limitless capacity, which makes them instrumental both in grid-connected applications and in remote areas.

What is all-vanadium redox flow battery (VRFB)?

All-vanadium redox flow battery (VRFB), as a large energy storage battery, has aroused great concern of scholars at home and abroad. The electrolyte, as the active material of VRFB, has been the research focus. The preparation technology of electrolyte is an extremely important part of VRFB, and it is the key to commercial application of VRFB.

Are vanadium redox flow battery electrolytes stable at high temperatures?

Insufficient thermal stability of vanadium redox flow battery (VRFB) electrolytes at elevated temperatures (>40 °C) remains a challenge in the development and commercialization of this technology, which otherwise presents a broad range of technological advantages for the long-term storage of intermittent renewable energy.

Is there a spectroscopic monitoring system for vanadium redox flow batteries?

An on-line spectroscopic monitoring system for the electrolytes in vanadium redox flow batteries RSC Adv., 5(2015), pp. 100235-100243, 10.1039/c5ra21844f

Are chloride ions an electrolyte additive for high performance vanadium redox flow batteries?

Chloride ions as an electrolyte additive for high performance vanadium redox flow batteries Appl. Energy, 289(2021), 10.1016/j.apenergy.2021.116690 Google Scholar M.Skyllas-Kazacos, L.Goh Modeling of vanadium ion diffusion across the ion exchange membrane in the vanadium redox battery

Which nanoparticle-modified carbon cloth electrode for vanadium redox flow batteries?

A uniformly distributed bismuth nanoparticle-modified carbon cloth electrode for vanadium redox flow batteries Appl. Energy, 240(2019), pp. 226-235, 10.1016/j.apenergy.2019.02.051 Google Scholar L.Wei, T.S.Zhao, L.Zeng, X.L.Zhou, Y.K.Zeng Copper nanoparticle-deposited graphite felt electrodes for all vanadium redox flow batteries

Related Articles

-

New all-vanadium liquid flow battery pump in Equatorial Guinea

New all-vanadium liquid flow battery pump in Equatorial Guinea

-

Malabo new all-vanadium liquid flow battery

Malabo new all-vanadium liquid flow battery

-

Swiss new all-vanadium liquid flow battery

Swiss new all-vanadium liquid flow battery

-

Tunisia s new all-vanadium liquid flow energy storage pump

Tunisia s new all-vanadium liquid flow energy storage pump

-

Bloemfontein new all-vanadium liquid flow energy storage pump

Bloemfontein new all-vanadium liquid flow energy storage pump

-

Bissau New All-Vanadium Redox Flow Battery Company

Bissau New All-Vanadium Redox Flow Battery Company

-

Graphite felt electrode all-vanadium liquid flow battery

Graphite felt electrode all-vanadium liquid flow battery

-

All-vanadium liquid flow battery temperature

All-vanadium liquid flow battery temperature

-

How much vanadium does a 1mw all-vanadium liquid flow battery use

How much vanadium does a 1mw all-vanadium liquid flow battery use

-

St John s UET All-Vanadium Flow Battery

St John s UET All-Vanadium Flow Battery

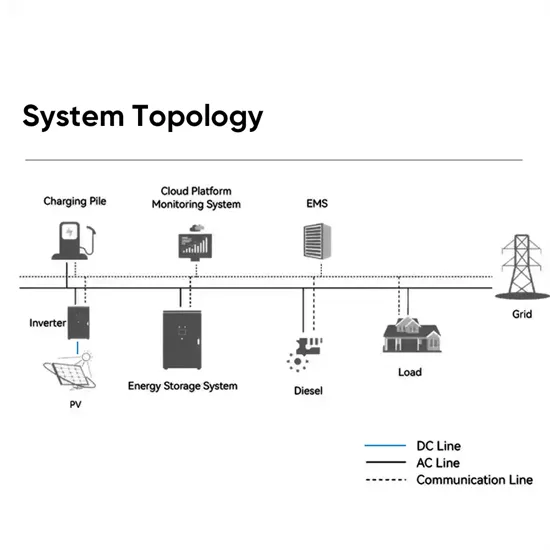

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

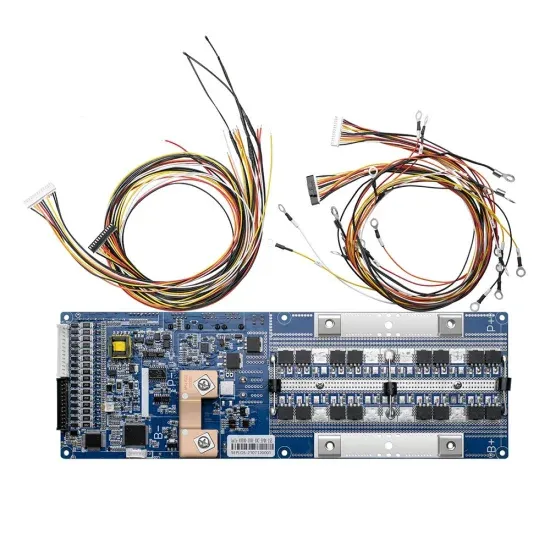

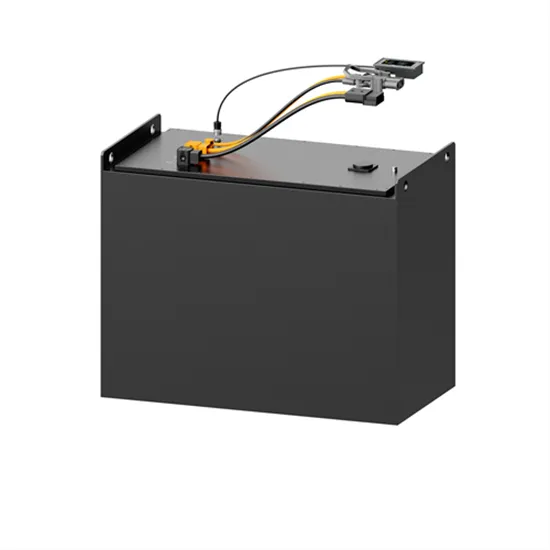

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.