SmartLi 3.0 User Manual (Short-Term Backup Power)

In the half-capacity cabinet scenario, connect the cable reserved on the rightmost side of the cabinet when you install a communications cable at the bottom layer.

Get Started

Battery Cabinet Inspection Form

Our team of experts works closely with you to design and install customized solar storage solutions that maximize efficiency and savings. From the initial consultation to the final

Get Started

Battery Inspection Checklist

Oct 10, 2024 · Regular inspections help to prevent unexpected failures, decrease downtime, and ensure the battery runs at its full capacity. This checklist

Get Started

Installation Procedure

Prepare for Installation. Install the Rear Seismic Anchoring. Position and Interconnect the Battery Cabinets. Install the Front Seismic Anchoring. Install the Battery Modules in the Battery

Get Started

VRLA Installation and Commissioning

Nov 6, 2018 · Batteries need to sway without breaking intercell connections and without sliding off the rack or shelf. Rack or cabinet manufacturers should

Get Started

Method Statement For Installation of Central

Jul 28, 2025 · • Check the label / marking to ensure the right system before installation • Fix the central battery system with proper metal plugs and bolts.

Get Started

UBC87 Battery Cabinet Installation, Operation,

Jul 21, 2025 · Review the battery system schematic that is located attached to the inside of a cabinet door to determine the number of batteries that need to be installed in the cabinet, the

Get Started

BC55 Battery Cabinet Installation, Operation,

Feb 3, 2025 · Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

Get Started

ZincFive BC Series UPS Battery Cabinets

Jun 9, 2023 · Once the cabinet has been placed at its final install location perform a final inspection. Follow all safety precautions when working on this system and always wear proper

Get Started

Best Practice for Distillation Column Internals Installation and Inspection

Dec 23, 2023 · Good column internal installation is vital for optimum tower performance, as well as trouble-free shutdowns. The mass transfer performance of a packed column is exceedingly

Get Started

SolaHD S4K-D External Battery Cabinent QIG Manual

Oct 2, 2024 · EmersonTM SolaHD® S4K-D 36V/48V/72V External Battery Cabinet IMPORTANT: Before installing, connecting to supply, or operating your Emerson SolaHD S4K-D UPS,

Get Started

UPS WITH A BATTERY SYSTEM 101. EDUCATION FOR

Jan 10, 2023 · The above questions are the basics on selecting a UPS with battery system, however there are many factors to consider. The most common topology of a UPS with a

Get Started

Mandatory inspection items for battery cabinets

Battery cabinet for safely charging lithium-ion batteries | Battery Batteryguard XL was tested during the development of VDMA 24994, in collaboration with European certification bodies

Get Started

BC58 Battery Cabinet Installation, Operation,

6.2.1 EQUIPMENT LOCATION Prior to installation, verify floor loading requirements and all applicable codes pertaining to the related equipment. Environmental conditions should also be

Get Started

Microsoft Word

Nov 15, 2017 · ESS ETC Series Top Terminal Battery Cabinets are shipped loaded with batteries partially assembled, internally pre-wired and come standard with an over current breaker.

Get Started

Application Guide: Outdoor E-Micromobility Battery

Apr 2, 2025 · Objective: This guide is designed to assist users in submitting a Request for E-Micromobility Charging Cabinet Site Survey Inspection. See below for a step-by-step guide.

Get Started

Inspection Battery

The battery is tested in accordance with DIN EN 50272-2 / IEC 62485-2 and the manufacturer''s specifications. It serves to ensure that the battery system is handled in accordance with the

Get Started

How to correctly install lithium battery energy

Mar 25, 2024 · Lithium battery energy storage cabinets can meet the needs of different large-scale projects and are very suitable for grid auxiliary services

Get Started

PDU8000 电池柜-T 快速指南 (02405362)

Jun 18, 2019 · 本文档主要介绍电池柜安装和调试的操作方法。2 Tools / 安装工具 4 Installing a Battery Cabinet / 安装电池柜 PDU8000 Battery Cabinet-T Quick Guide 4.1 Checking Before

Get Started

On-site inspection of battery cabinet

Inspection Checklist for Your Lithium-ion Battery Charging Cabinet. Schedule routine inspections and maintenance (test and tag) by a certified electrician ; IMPORTANT: We recommend

Get Started

SolaHD S4K-D External Battery Cabinent QIG Manual

Oct 2, 2024 · The external battery cabinet (EBC) is used to house external batteries for the UPS. Before shipment, each battery cabinet model was fitted with a different number of 12Vdc

Get Started

U-ENM00044

Feb 3, 2025 · Install the battery cabinet using adjustable leveling legs to ensure the cabinet is level and stable. Ensure the surface supporting the battery cabinet is rated to withstand the

Get Started

Packed Columns & Packing Installation and

6 days ago · Packing & Column Internals Installation & Maintenance The installation and maintenance of packing & column internals is the key to

Get Started

Inspection and Test Plan for UPS, Batteries & DC

Full ITP Template for Batteries, DC Chargers & UPS Installation at Construction Sites with Inspection Checklists in MS Word & Excel Format to Customize to

Get Started

2018 Title Contents

Dec 20, 2022 · Abstract Changes in requirements to meet battery room compliance can be a challenge. Local Authorities Having Jurisdictions often have varying requirements based on

Get Started

Galaxy Lithium-ion Battery Cabinet Installation and

Dec 23, 2024 · This manual provides installation and operation instructions for the Galaxy Lithium-ion Battery Cabinet.

Get Started

The BESS System: Construction, Commissioning,

3 days ago · The guide is divided into three main sections: construction and installation, commissioning, and operation & maintenance. It covers various

Get Started

BATTERY INSPECTION CHECKLIST

Oct 10, 2024 · Note: Battery should be Replaced if ~ Point 2,4 & 7: Badly damage ~ Point 16: < 6,5 VDC or < 300A Battery should be Recharged if ~ All Visual Inspection OK ~ Point 16 in

Get Started

USER MANUAL BATTERY CABINET

Jun 26, 2025 · 3.1 SAFETY INSTRUCTIONS Before beginning any work, carefully read all safety instructions, and always observe them when working on or with the cabinet and/or batteries.

Get Started

White Paper | Battery Inspection, Maintenance, and Testing

2 days ago · Discover best practices for battery inspection, maintenance, and testing in this expert white paper from Eagle Eye Power Solutions. Learn how to enhance battery reliability and

Get Started

Inspection Checklist for Your Lithium-ion Battery

Apr 4, 2024 · Read our inspection checklist and make sure your Storemasta Lithium-ion Battery Charging Cabinet is in top condition.

Get Started

New energy battery cabinet inspection and maintenance

The Rack Series cabinets are an elegant IP21 indoor battery cabinet that are pre-wired for an easy plug and play installation of our LiFe or ECO P Series batteries.

Get Started

Battery Cabinet

Feb 28, 2025 · Install the Battery Cabinet following local building requirements and applicable codes. Plan the location of the Battery Cabinet site ahead of time, taking into consideration the

Get Started

Mitsubishi Electric Power Products, Inc. BC43 Battery

Feb 3, 2025 · Battery cabinets that are not supplied with an incorporated DC output disconnect device must have an appropriate disconnect device provided external to the cabinet.

Get Started

4 FAQs about [Battery cabinet inspection column installation]

What is a battery inspection checklist?

Regular battery inspections assist to ensure optimal performance & safety. Following this checklist makes sure that all important components are evaluated and any necessary steps are performed to keep the system operational. This detailed Battery Inspection Checklist ensures battery performance and safety.

What is a battery inspection?

The first level of inspection involves a thorough visual examination of the battery’s physical condition. This step checks for any mechanical or structural faults that could hinder performance. Mark “OK,” “Not OK,” or “N/A” in the appropriate boxes for each point.

How do you test a battery?

Battery Load Test: Perform a load test by providing a 200A load for 10-15 seconds. The voltage per battery should not fall below 9.6 V DC. Open/Short Circuit Check: Make sure the battery system has no open or short circuits. According to the inspection results, follow these recommendations:

How do you check a battery in a washing machine?

Unit Number: Write down the machine unit number in which the battery is placed. Note the machine’s model. Last Fitment Date: Mention the date that the battery was last installed in the machine. The first level of inspection involves a thorough visual examination of the battery’s physical condition.

Related Articles

-

Emergency battery cabinet installation price base station

Emergency battery cabinet installation price base station

-

Battery cabinet installation site in weak current room

Battery cabinet installation site in weak current room

-

The function of the battery cabinet maintenance column

The function of the battery cabinet maintenance column

-

Installation of voltage stabilized power supply battery cabinet

Installation of voltage stabilized power supply battery cabinet

-

Battery cabinet water cooling device installation location

Battery cabinet water cooling device installation location

-

Integrated system for outdoor communication battery cabinet installation in South Africa

Integrated system for outdoor communication battery cabinet installation in South Africa

-

UPS battery cabinet installation site

UPS battery cabinet installation site

-

Battery cabinet battery installation site

Battery cabinet battery installation site

-

Energy storage cabinet battery installation time

Energy storage cabinet battery installation time

-

Battery cabinet wiring installation ESS power base station

Battery cabinet wiring installation ESS power base station

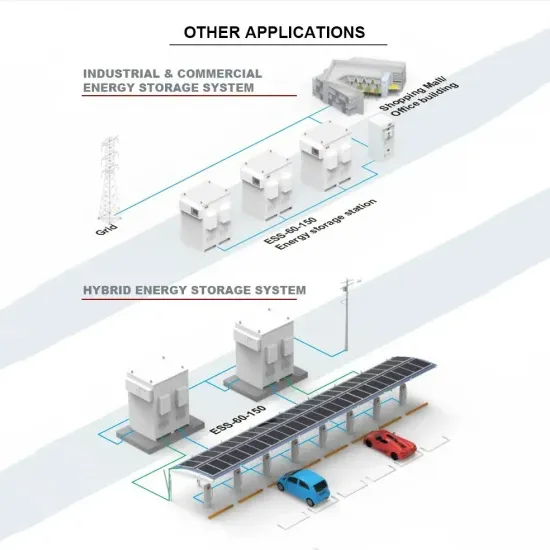

Commercial & Industrial Solar Storage Market Growth

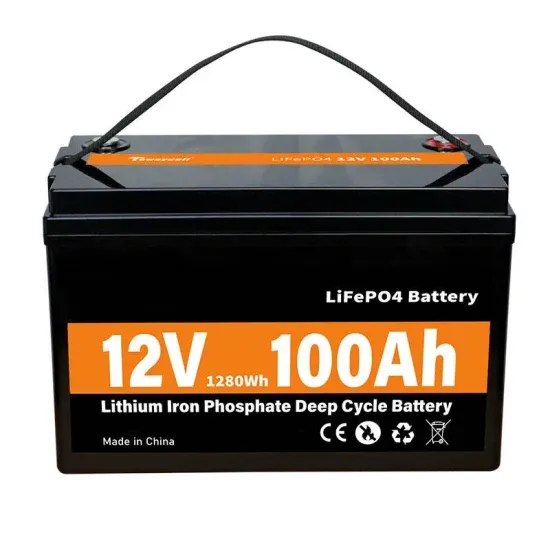

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

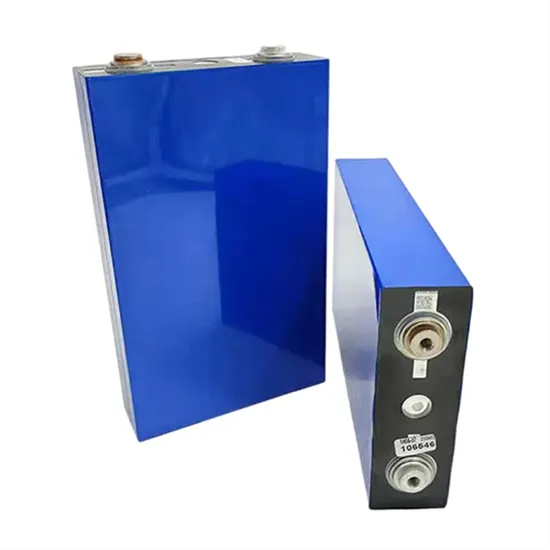

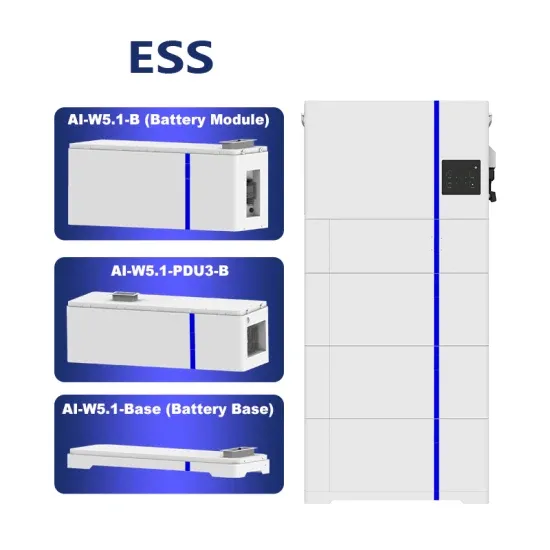

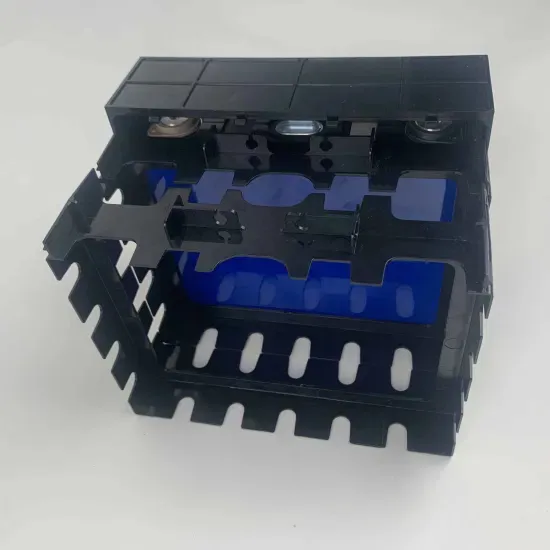

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.