What does the energy storage power station use to cool

May 25, 2024 · The cooling methodologies within energy storage power stations are instrumental in ensuring efficient operation and longevity of these critical systems. Liquid cooling systems,

Get Started

Regulatory Standards for Cooling Towers in the United States

Sep 3, 2024 · Wahaso Outlines the Regulatory Standards for Cooling Towers in the United States Cooling towers are critical components in various commercial and industrial applications, such

Get Started

(PDF) A Review Study On Cooling Towers; Types

Sep 14, 2018 · The cooling component of this new electricity station is a natural draft cooling tower 200 m high, the tallest cooling tower and the largest shell

Get Started

COOLING TECHNIQUES AT ESKOM POWER STATIONS

Aug 24, 2021 · steam, condensation of the steam occurs. The warmed cooling water flows to a cooling tower where an upward draft of air removes the heat from the water, evaporation so

Get Started

How Do Cooling Towers Work: A Beginner''s Guide

Cooling towers are essential to industries and facilities that depend on temperature regulation to function efficiently. From power plants and

Get Started

A Review on Cooling Towers of Power Plants

Sep 27, 2023 · Abstract: Cooling towers are used in a variety of applications; from the 400-foot-tall towers at nuclear power plants to small 4 foot cooling boxes used by neighborhood dry

Get Started

COOLING TECHNIQUES AT ESKOM POWER STATIONS

Aug 24, 2021 · Wet cooling (the conventional system used world wide) use condensers, cooling water and cooling towers. The cooling water flows through thousands of condenser tubes, with

Get Started

Renewable Energy Technology Characterizations

Nov 15, 2007 · The Solar One thermal storage system stored heat from oil as the heat-transfer fluid. The system extended heat for generating low-grade steam for keeping parts .

Get Started

How Cooling Towers Work

Feb 13, 2025 · How are cooling towers relate to Atmospheric Vortex Engines? Cooling towers are normally required to transfer the heat from power plants to

Get Started

Energy Storage System Cooling

May 5, 2025 · According to FCC order 07-177, when the power to a cellular antenna tower goes out, emergency batteries must provide back-up power for at least 8 hours. Many base stations

Get Started

Cooling Towers in the Power Industry: Function

Jan 17, 2025 · Industrial cooling towers are important components in the power generation industry, providing an efficient method to manage and dissipate the

Get Started

The Impact of Cooling Towers on Power Generation: A

Nov 15, 2024 · Cooling towers are indispensable components in the operation of power plants. They perform the critical task of managing the excess heat generated during power

Get Started

Cooling Tower Cost Estimate: Average Price in

Jan 21, 2022 · The cost of a cooling tower varies based on factors like the model of the tower, tonnage, horsepower-per-ton, etc. Let''s see how these factors

Get Started

Cooling Towers: Understanding Key Components of

Cooling towers can be a significant source of water use for both of these cat-egories of water use at Federal facilities. To realize potential savings it is essential for Federal agencies understand

Get Started

Why do power stations need cooling towers?

Cooling towers provide an energy efficient and environmentally friendly way of removing heat from this circulating water before it is returned to its source. So while they are so closely identified

Get Started

Power Plant Cooling Tower: Function, Types & Design

Learn about power plant cooling towers—their function, types, and design essentials for efficient heat removal and sustainable energy operations

Get Started

Evaporative Cooling Applied in Thermal Power Plants: A

A review is conducted about the application of the evaporative cooling technology in thermal power plants. Different case studies are considered, namely, evaporative air conditioners,

Get Started

Designing an energy storage system based on water tower

May 1, 2024 · In the last part of the research, an energy storage system was designed to store the generated electrical energy. For this purpose, an energy storage system based on water

Get Started

Cooling Water Options for the New Generation of

Mar 13, 2014 · Cooling water is required to remove "waste heat" from power stations regardless of whether the stations are nuclear or conventional. A nuclear power station has a typical thermal

Get Started

Cooling towers: what are they and how do they

Oct 14, 2021 · So, what purpose does the cooling tower serve? It depends. Thermoelectric power plants, like Harris, that use heat to make steam to spin

Get Started

Cooling Tower 101: All You Need To Know

Jul 2, 2021 · Thanks to the cooling process of a water stream, a cooling tower takes in heat and puts the air into the atmosphere at a much cooler

Get Started

Battery storage power station – a comprehensive

2 days ago · This article provides a comprehensive guide on battery storage power station (also known as energy storage power stations). These facilities

Get Started

The Role of Cooling Towers in Renewable Energy

Feb 14, 2025 · As the world transitions toward sustainable and clean energy, renewable energy systems such as solar thermal, geothermal, biomass, and

Get Started

Energy storage power station water cooling system

Storage capacity is the amount of energy extracted from an energy storage device or system; usually measured in joules or kilowatt-hours and their multiples, it may be given in number of

Get Started

Energy storage power station water cooling system

Fig. 1 a shows the schematic of a CSP plant with an evaporative wet-cooling tower, supplemented by a radiative cooling system and cold storage tanks. Fig. 1 a also highlights several design

Get Started

7. COOLING TOWER

Sep 8, 2017 · An energy efficient or low power consuming cooling tower is to have efficient designs of fill media with appropriate water distribution, drift eliminator, fan, gearbox and motor.

Get Started

Cooling Tower Energy

6 days ago · The pump-head of a cooling tower also contributes to the energy expended in the operation of the condenser water pump. Obviously, therefore, manipulation of one, or both, of

Get Started

Why do power stations need cooling towers?

Why do power stations need cooling towers? As the name suggests, a cooling tower''s primary function is to lower temperatures – specifically of water, or ''cooling water'' as it''s known at

Get Started

6 FAQs about [Does an energy storage power station need a cooling tower ]

What is a cooling tower & how does it work?

As the name suggests, a cooling tower’s primary function is to lower temperatures – specifically of water, or ‘cooling water’ as it’s known at Drax. Power stations utilise a substantial amount of water in the generation of electricity.

Why do power plants need cooling towers?

Cooling towers ensure that the reactor and other components maintain safe operating temperatures, playing a key role in the plant's safety systems. Industrial cooling towers are indispensable in the power generation industry, ensuring that power plants operate efficiently, safely, and with minimal environmental impact.

Why are industrial cooling towers important?

Industrial cooling towers are important components in the power generation industry, providing an efficient method to manage and dissipate the enormous amounts of heat produced during electricity generation. These towers are essential for maintaining system efficiency, conserving water, and preventing environmental damage.

Why are energy storage systems important?

Energy storage systems (ESS) have the power to impart flexibility to the electric grid and offer a back-up power source. Energy storage systems are vital when municipalities experience blackouts, states-of-emergency, and infrastructure failures that lead to power outages.

What are the different types of cooling towers used in power generation?

Different types of cooling towers are used in power generation, depending on the plant's requirements and environmental conditions: Natural Draft Cooling Towers: These are often used in large power plants. They rely on natural convection to circulate air and remove heat, characterized by their iconic hyperboloid structure.

Will a cooling tower be a mantle of energy?

As they continue to be part of our energy mix, the cooling tower will remain an icon of electricity generation for the time being. But it’ll be a mantle it shares with biomass domes, gigantic offshore wind turbines and field-upon-field of solar panels – the icons of today’s diverse energy mix.

Related Articles

-

Liquid cooling of Canadian energy storage power station

Liquid cooling of Canadian energy storage power station

-

Cooling system of container energy storage power station

Cooling system of container energy storage power station

-

Small energy storage power station voltage

Small energy storage power station voltage

-

Electrochemical Energy Storage Power Station General Contractor

Electrochemical Energy Storage Power Station General Contractor

-

Vatican Independent Energy Storage Power Station

Vatican Independent Energy Storage Power Station

-

User energy storage power station composition

User energy storage power station composition

-

Mobile Energy Storage Power Station Container Manufacturer Ranking

Mobile Energy Storage Power Station Container Manufacturer Ranking

-

Comoros Enterprise Energy Storage Power Station

Comoros Enterprise Energy Storage Power Station

-

Luanda air compression energy storage power station

Luanda air compression energy storage power station

-

Power station energy storage hydrogen energy

Power station energy storage hydrogen energy

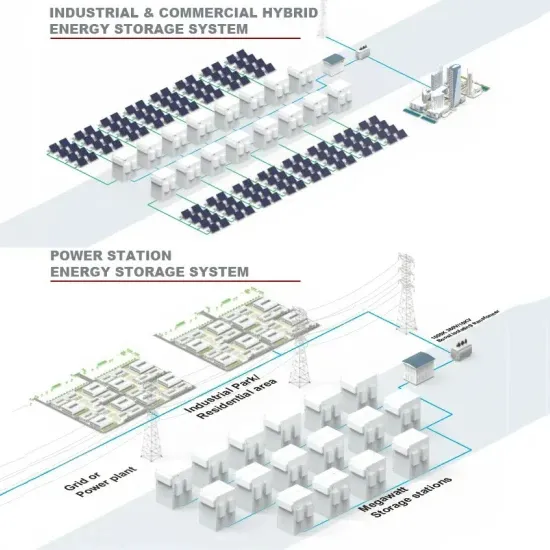

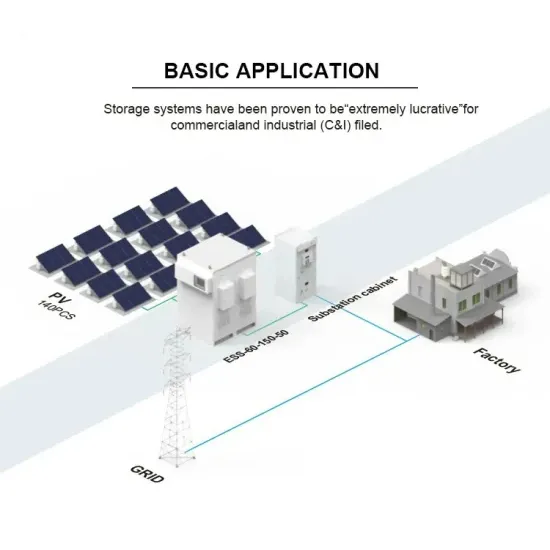

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.