Optimized the vanadium electrolyte with sulfate-phosphoric

The sulfate-phosphoric mixed acid system electrolyte promotes the electrode reaction process, increases the current density, and reduces the resistance. This work systematically optimizes

Get Started

Understanding the Role of Battery Acid in Automotive

Jun 21, 2024 · Battery acid primarily refers to sulfuric acid, which is utilized in conventional lead-acid car batteries. This type of acid plays a critical role, as it facilitates the electrochemical

Get Started

How Lead-Acid Batteries Work

Feb 14, 2025 · Lead-acid batteries work by harnessing the chemical reactions between lead plates and sulfuric acid to store and release electrical energy.

Get Started

10.2 Batteries and Electrolytic Cells

The lead–acid battery is a common battery used to provide the starting power in virtually every automobile and marine engine on the market. Marine and car

Get Started

Revealing the role of phosphoric acid in all-vanadium redox flow

Jan 1, 2018 · The present work suggests the use of a mixed water-based electrolyte containing sulfuric and phosphoric acid for both negative and positive electrolytes of a vanadium redox

Get Started

Unveiling the Significance of Sulfuric Acid in Lead Acid Battery

Apr 11, 2025 · Sulfuric acid acts as the electrolyte, facilitating ion exchange between lead plates during charging and discharging. Its high acidity allows dissolution of sulfate ions (SO₄²⁻),

Get Started

Sulfuric Acid in Battery Manufacturing

Why Is Sulfuric Acid Essential for Lead-Acid Batteries? Sulfuric acid plays a crucial role in battery function due to its: High Ionic Conductivity – Enhances

Get Started

The Unseen Backbone of Battery Recycling: Sulfuric Acid''s

Jun 18, 2025 · As the world accelerates its transition to clean energy, sulfuric acid is quietly assuming a pivotal role in battery recycling and critical mineral recovery —key pillars of the

Get Started

Reasons why a battery contains acid

Jan 14, 2024 · So, in summary, lead plays a crucial role in the acidification of a battery. It reacts with sulfuric acid during discharge and then regenerates during charging, causing the battery

Get Started

What is Battery Acid and How Does it Work

Jan 14, 2024 · Battery acid, also known as sulfuric acid, is a highly corrosive liquid that plays a critical role in the functioning of batteries. To understand what battery acid is made up of and

Get Started

Novel electrolyte design for high-efficiency vanadium redox flow

Jul 15, 2025 · Improved broad temperature adaptability and energy density of vanadium redox flow battery based on sulfate-chloride mixed acid by optimizing the concentration of electrolyte

Get Started

Electrolyte tank costs are an overlooked factor in flow battery

Jan 3, 2025 · Quotes from globally distributed sulfuric acid storage tank manufacturers demonstrate that electrolyte tank costs are a substantial factor in flow battery development

Get Started

Revealing sulfuric acid concentration impact on

Apr 20, 2019 · The redox flow batteries (RFBs) play a crucial role among them due to many merits including unlimited capacity and power, long cycle life, environmental friendliness and high

Get Started

The role of phosphate additive in stabilization of sulphuric-acid

Sep 30, 2017 · Catholyte in all-vanadium redox-flow battery (VRFB) which consists of vanadium salts dissolved in sulphuric acid is known to be stabilized by phosphoric acid to slow down the

Get Started

Adjustment of Electrolyte Composition for

Oct 16, 2023 · Commercial electrolyte for vanadium flow batteries is modified by dilution with sulfuric and phosphoric acid so that series of electrolytes with

Get Started

Flow Cell for Simultaneous In Situ Analysis of Local

May 17, 2023 · Serving as both the electrolyte and the active material, sulfuric acid is a crucial component in all lead-acid batteries. It provides the medium for mass transfer and ionic charge

Get Started

Battery Acid Ph: Optimizing Electrolyte Concentration

Sep 24, 2024 · Sulfuric acid, with its fiery reputation, is a potent acid that acts as the electrolyte in batteries. This means it provides the conductive medium for the flow of electrical current. In

Get Started

Battery Acid: Name, Supphuric Acid, pH, and Role in Car Batteries

Battery acid is the liquid electrolyte inside a lead-acid battery. This liquid is a mixture of sulfuric acid (H₂SO₄) and water. It plays a vital role in storing and releasing electrical energy through

Get Started

Comprehensive Guide to Battery Acid: Its

Oct 3, 2024 · Battery acid, primarily composed of sulfuric acid (H₂SO₄), is a highly corrosive liquid used in certain types of batteries, particularly lead-acid

Get Started

Sulfuric Acid in Battery Manufacturing

Sulfuric acid plays a crucial role in battery function due to its: High Ionic Conductivity – Enhances electron flow between the battery plates. Efficient

Get Started

Why Is Sulfuric Acid Used in Car Batteries? Explained

May 13, 2025 · At the cathode, lead dioxide reacts with sulfuric acid and the electrons from the anode to form lead sulfate and water. This process effectively completes the circuit, allowing

Get Started

On the significance of sulphuric acid dissociation in the

Aug 1, 2020 · A recent asymptotic model for the operation of a vanadium redox flow battery (VRFB) is extended to include the dissociation of sulphuric acid—a bulk chemical reaction that

Get Started

The Vital Role of Sulfuric Acid in Battery Acid

By understanding the benefits of sulfuric acid in battery acid production, manufacturers can optimize their production processes and create high-quality

Get Started

Acid For Batteries: Types, Functions & Safety Guide

Jul 5, 2025 · What is sulfuric acid used for in batteries? Sulfuric acid is mainly used as the electrolyte in lead-acid batteries. It helps in the chemical reactions that produce electricity.

Get Started

The Vital Role of Sulfuric Acid in Battery Acid

In the production of lead-acid batteries, sulfuric acid plays a vital role as an electrolyte. The electrolyte is a chemical substance that facilitates the flow of

Get Started

Review of vanadium redox flow battery technology

Vanadium redox flow battery (VRFB) has a brilliant future in the field of large energy storage system (EES) due to its characteristics including fast response speed, large energy

Get Started

Revealing the Role of Phosphoric Acid in All-Vanadium Redox Flow

Aug 31, 2018 · Abstract The present work suggests the use of a mixed water-based electrolyte containing sulfuric and phosphoric acid for both negative and positive electrolytes of a

Get Started

Decoding the Electrolyte-Involved Chemical Reactions in Lead Acid Batteries

Apr 11, 2025 · Lead acid batteries generate electricity through electrolyte-driven chemical reactions. During discharge, sulfuric acid (H₂SO₄) reacts with lead plates, producing lead

Get Started

What is Battery Acid? Learn About its Composition and Uses

Jan 14, 2024 · Battery acid, also known as electrolyte, is a solution that is commonly found in lead-acid batteries. This acid is a vital component of the battery, as it plays a crucial role in its

Get Started

How Acid Powers Your Car Battery | ShunAuto

Apr 24, 2025 · Car batteries are fascinating components that power vehicles. The liquid in car batteries is typically a corrosive substance known as battery acid

Get Started

Comprehensive Guide to Battery Acid: Its

Oct 3, 2024 · Understanding Battery Acid: Types, Uses, and Safety Battery acid, primarily composed of sulfuric acid (H₂SO₄), is a highly corrosive liquid used

Get Started

Types of Battery Acid Used in Different Batteries

Jan 14, 2024 · Overall, sulfuric acid plays a crucial role in the functionality of lead-acid batteries, providing the necessary electrolyte for the battery cells. Its corrosive nature and strong

Get Started

6 FAQs about [The role of sulfuric acid in flow batteries]

How does sulfuric acid affect a car battery?

The sulfuric acid solution, known as the electrolyte, facilitates the flow of ions between the electrodes, enabling the chemical reactions that generate electricity. When a car battery is connected to a circuit, a chemical reaction occurs at both electrodes.

Why is sulfuric acid a good battery?

Sulfuric acid has a relatively low vapor pressure, meaning it does not easily evaporate. This property helps to prevent the loss of electrolyte from the battery, ensuring its longevity. Sulfuric acid has a high density, which contributes to the overall weight of the battery. This density also helps to maintain the battery’s structural integrity.

Why is sulfuric acid used in energy storage?

Sulfuric acid serves as the electrolyte in these batteries, facilitating the flow of electrons and thus allowing the battery to generate and store energy efficiently. One of the major advantages of using battery acid in energy storage is its ability to deliver high surges of electricity.

Why is sulfuric acid a good electrolyte?

Sulfuric acid acts as the electrolyte catalyst, enabling ion transfer between lead plates. It dissociates into H⁺ and SO₄²⁻ ions during discharge, facilitating electron flow through external circuits. Optimal specific gravity (1.22-1.28) ensures peak conductivity.

What is battery acid?

Battery acid, primarily composed of sulfuric acid (H₂SO₄), is a highly corrosive liquid used in certain types of batteries, particularly lead-acid batteries. This powerful acid plays a pivotal role in the batteries’ energy storage and ability to produce power on demand.

Is sulfuric acid a good electrolyte for car batteries?

The answer lies in a surprisingly simple yet powerful chemical: sulfuric acid. Sulfuric acid, with its distinctive pungent odor, might seem like an unlikely hero in the world of automotive technology. However, its unique properties make it the perfect electrolyte for lead-acid batteries, the most common type found in cars today.

Related Articles

-

Environmental assessment requirements for liquid flow batteries for communication base stations

Environmental assessment requirements for liquid flow batteries for communication base stations

-

10 billion flow batteries

10 billion flow batteries

-

What are the photovoltaic power generation of flow batteries in Kiribati communication base stations

What are the photovoltaic power generation of flow batteries in Kiribati communication base stations

-

The prospects of zinc-nickel flow batteries

The prospects of zinc-nickel flow batteries

-

Approval of liquid flow batteries for communication base stations

Approval of liquid flow batteries for communication base stations

-

Advantages and disadvantages of high-efficiency liquid flow batteries

Advantages and disadvantages of high-efficiency liquid flow batteries

-

Commercialization of vanadium flow batteries

Commercialization of vanadium flow batteries

-

Several types of flow batteries

Several types of flow batteries

-

Industry standards for flow batteries

Industry standards for flow batteries

-

Georgia Energy Storage Lead Acid Batteries

Georgia Energy Storage Lead Acid Batteries

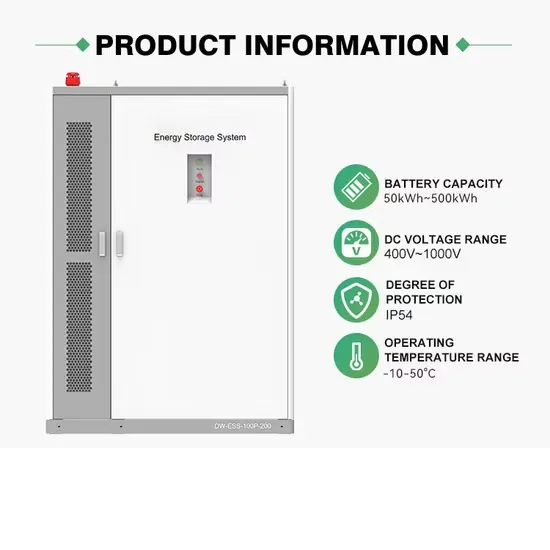

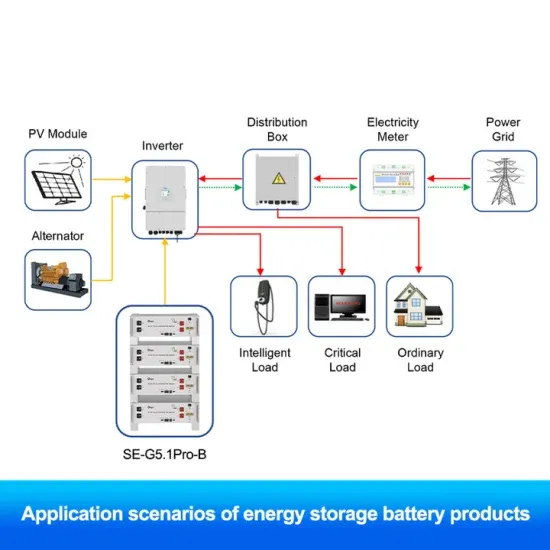

Commercial & Industrial Solar Storage Market Growth

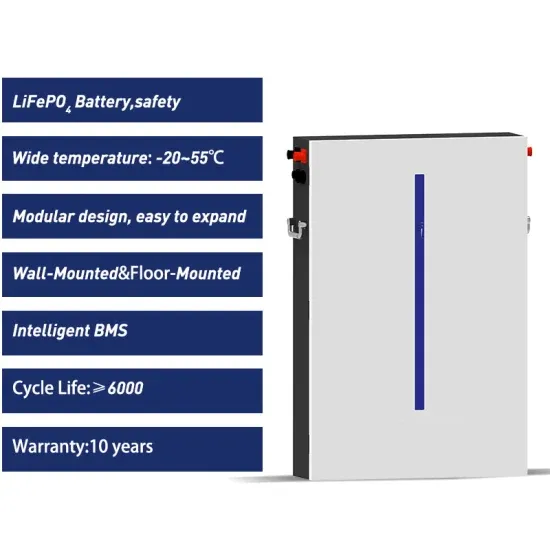

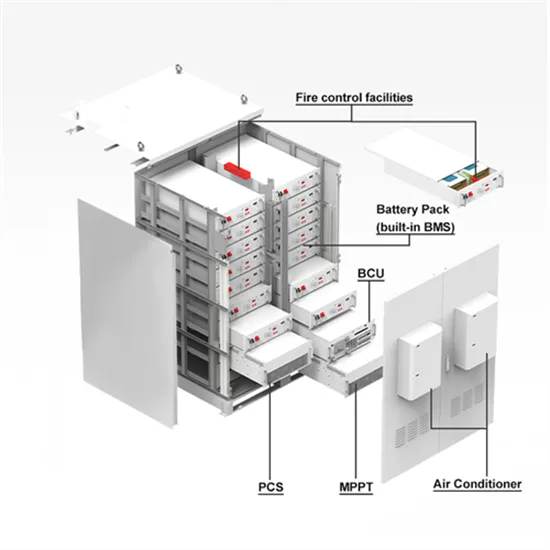

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

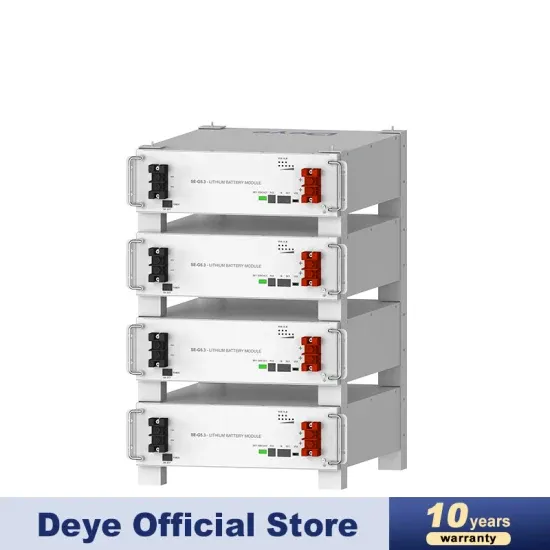

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.