What is a shingled solar cell? | NenPower

Apr 18, 2024 · What you refer to as shingled solar cells represents an innovative approach in photovoltaic technology that enhances efficiency and

Get Started

A Comprehensive Guide to Solar Panel

4 days ago · The solar energy industry has experienced significant advancements, resulting in a variety of solar panel technologies tailored to

Get Started

Shingled Solar Panels vs Monocrystalline | What Apart Them

Jul 27, 2023 · In short, shingled solar panels are made of many small, overlapping solar cells and tend to be more efficient but also more expensive than traditional monocrystalline panels.

Get Started

Which is better single crystal photovoltaic panel or

Oct 19, 2022 · The monocrystalline solar panels are also known as the single crystal panels. They are made from pure silicon crystal which is sliced into several wafers forming cells.

Get Started

What are shingled solar panels? | NenPower

Sep 7, 2024 · Shingled solar panels are a type of photovoltaic technology characterized by their unique design, which consists of overlapping solar cells

Get Started

What does shingled solar energy mean?

Aug 1, 2024 · 1. Shingled solar energy refers to a specific type of solar panel design characterized by overlapping cells that are arranged in a staggered

Get Started

Different Types of Solar Panels & How to Select

Aug 10, 2024 · Manufacturing Process: The production of monocrystalline panels involves the Czochralski method, where a single crystal seed is placed in

Get Started

What are shingled solar panels?

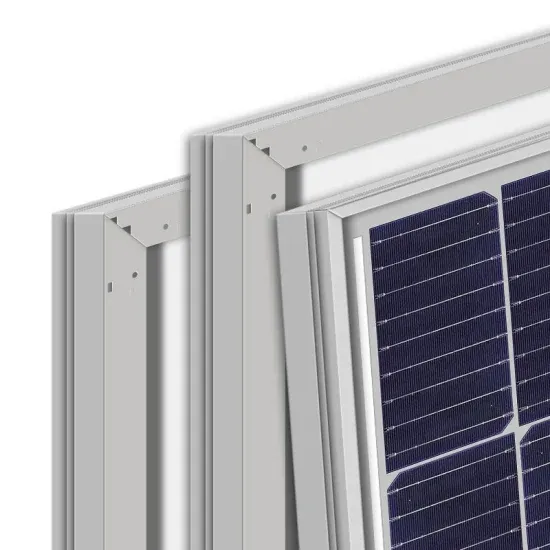

Aug 3, 2020 · The shingled solar cells do not require busbars across the top of the cells so more of the solar cells are exposed to sunlight. The cells do not

Get Started

The Evolution of Shingled-Cell Solar Panels: Advantages Over

Sep 9, 2024 · Unlike traditional solar modules, which rely on larger, intact cells connected by visible busbars, shingled panels employ a unique cell arrangement that boosts performance

Get Started

A Comprehensive Guide to the Different Types

There are many different types of solar cells – monocrystalline, polycrystalline and amorphous to name a few. Monocrystalline solar cells are made from single

Get Started

Which is better single crystal silicon or solar cell

Monocrystalline solar cells are solar cells made from monocrystalline silicon, single-crystal silicon. Monocrystalline silicon is a single-piece crystal of high purity silicon.

Get Started

Single crystal Perovskite-Based solar Cells: Growth,

Jun 15, 2023 · Therefore, single-crystal perovskite solar cells (SC-PSCs) have recently received significant attention in the fabrication of highly efficient and stable PSCs owing to their

Get Started

Difference between PV Shingled Modules and

Therefore, shingled modules have the advantages of high output power, low internal loss, and small reverse current hot spot effect. The key to shingled

Get Started

WHAT ARE SHINGLED SOLAR PANELS?

Nov 20, 2020 · Conventional solar panels use various numbers of solar cells depending on the desired output of the panel. The solar cells are laid out

Get Started

Shingled Solar Panels vs. Traditional Solar Panels

May 8, 2025 · Shingled solar panels offer a fresh perspective on clean energy with their innovative design and efficiency. In this blog post, we''ll guide you

Get Started

Silver-free intrinsically conductive adhesives for shingled

May 6, 2024 · Silver-free intrinsically conductive adhesives for shingled solar cells The accelerated growth of solar photovoltaics needed to reduce global carbon emissions requires

Get Started

Shingled solar panels | Alternergy

Jun 22, 2023 · Shingled Cell Technology In recent years, the market for solar modules significantly changed from more or less exclusively ribbon-based

Get Started

what is shingled solar panel?

Shingled solar panel components are made by slicing traditional battery cells (single crystal, polycrystalline, Sunpower, etc.) and connecting each small

Get Started

Electrically Conductive Adhesives as Cell Interconnection

Dec 9, 2020 · Abstract. Modules, in which pre-cut crystalline silicon solar cells – or shingles – are assembled into solar modules by placing the pre-cut cells in a shingle-like way on top of each

Get Started

Which is better, solar shingles or single crystals? | NenPower

May 21, 2024 · 1. SOLAR SHINGLES HAVE UNIQUE ADVANTAGES, INCLUDING INTEGRATION INTO ROOFS, AESTHETICS, AND LESS VISIBILITY THAN SOLAR

Get Started

SHINGLED SOLAR PANEL

Which is better single crystal photovoltaic panel or shingled photovoltaic panel In short, shingled solar panels are made of many small, overlapping solar cells and tend to be more efficient but

Get Started

Different Types of Solar Panels & How to Select Best One?

Aug 10, 2024 · Shingled solar panels use a unique design where solar cells are cut into strips and overlaid in a shingled pattern, similar to roof shingles. This design eliminates the gaps

Get Started

What Are Shingled Solar Panels and How Do They Work

Jul 3, 2025 · Shingled solar panels feature overlapping cell strips for higher efficiency, better shade tolerance, sleek aesthetics, and growing industry adoption.

Get Started

Polycrystalline Solar Cells vs Monocrystalline:

Nov 8, 2024 · Monocrystalline solar panels have a sleek, black appearance and are made from a single silicon crystal. They have a higher efficiency rating and

Get Started

Shingle Solar Cells and Modules

In addition, shingled solar cells reflect less light, and thus generate more electricity. The adaptation of solar cell production from the conventional

Get Started

Monocrystalline vs Polycrystalline

Aug 12, 2024 · A polycrystalline, or multicrystalline, solar panel consists of multiple silicon crystals in a single photovoltaic (PV) cell. This differentiates it

Get Started

Monocrystalline Vs Polycrystalline Solar Panels

Jun 16, 2022 · Polycrystalline solar panels have a cost advantage and are more affordable compared to other solar panels. The polycrystalline solar panel or

Get Started

6 FAQs about [Which is better single crystal solar cell or shingled solar cell ]

Are shingled solar panels better than conventional solar panels?

While standard panels might not be the most attractive as they have several circuitries visible across the modules’ area, shingled solar cells improve the building design by getting rid of many of the ribbons and busbars used in conventional panels.

What is the difference between solar shingles and solar panels?

While solar shingles and solar panels generate electricity with the same fundamental photovoltaic effect, they have significant installation differences. Solar shingles are not mounted on racks like other solar panels. Instead, they are attached directly to the roof deck in place of conventional roofing shingles.

What is the difference between conventional and shingled solar cells?

However, the most relevant difference between conventional and shingled solar cells in terms of their composition and structure—is the interconnection or layout of them. Every solar panel contains different amounts of cells interconnected or arranged in different ways depending on the desired output.

What are the advantages of crystalline solar cells?

High efficient solar cells, the construction prevents failures: Crystalline solar cells are made of silicon, which can be thought of as an approximately 0.2 mm thick glass sheet. The silicon endures even small deformations easily. Silicon is limited flexible and therefore fragile.

What are the different types of solar panels?

Half-Cut Cell Layout: Reduces resistance and increases efficiency, often used with monocrystalline and PERC cells. Bifacial Solar Panels: Capture sunlight from both sides, typically paired with N-type cells (TOPCon, HJT) to maximise efficiency. Shingled Cell Layout: Higher efficiency and power density, often used with HJT or monocrystalline cells.

Which type of solar cell is best?

Efficiency: Moderate to high, depending on the technology (e.g., standard monocrystalline, PERC). Proven Technology: P-type silicon is the traditional choice for solar cells, offering a balance of efficiency and cost-effectiveness. Cost-Effective: Lower production costs compared to N-type cells.

Related Articles

-

How many watts does a single crystal solar cell have

How many watts does a single crystal solar cell have

-

Which brand of photovoltaic solar energy is better

Which brand of photovoltaic solar energy is better

-

Which outdoor solar energy source is better

Which outdoor solar energy source is better

-

Which solar base station in Jerusalem is better

Which solar base station in Jerusalem is better

-

Single crystal high efficiency solar photovoltaic panels

Single crystal high efficiency solar photovoltaic panels

-

Single crystal silicon lighting solar lamp

Single crystal silicon lighting solar lamp

-

Which solar panel is better for communication base stations

Which solar panel is better for communication base stations

-

Which energy storage power supply is better in Mombasa Kenya

Which energy storage power supply is better in Mombasa Kenya

-

Which brand is better for 12v inverter 220v

Which brand is better for 12v inverter 220v

-

Which imported solar energy storage cabinet is the best

Which imported solar energy storage cabinet is the best

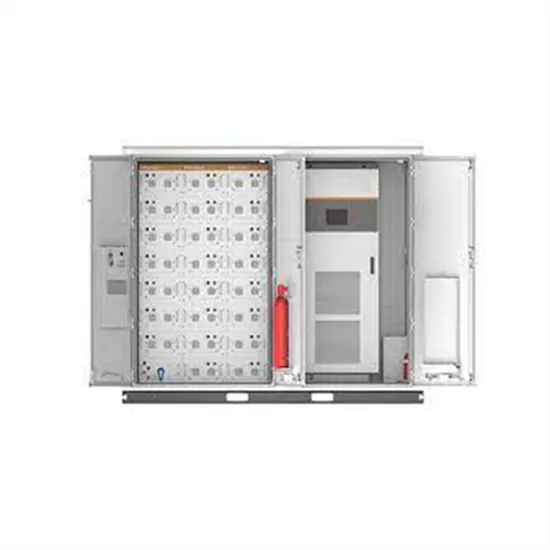

Commercial & Industrial Solar Storage Market Growth

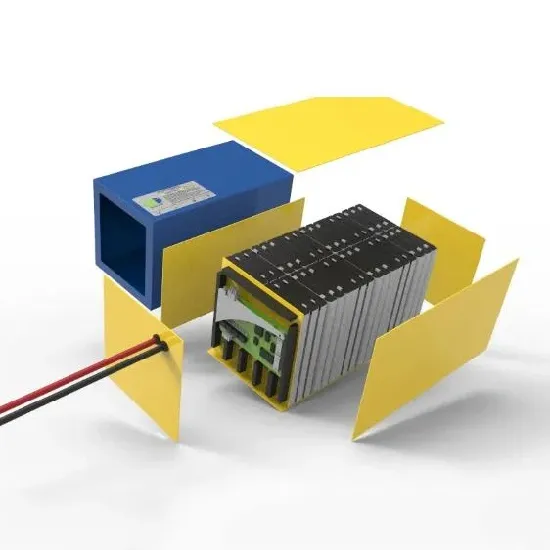

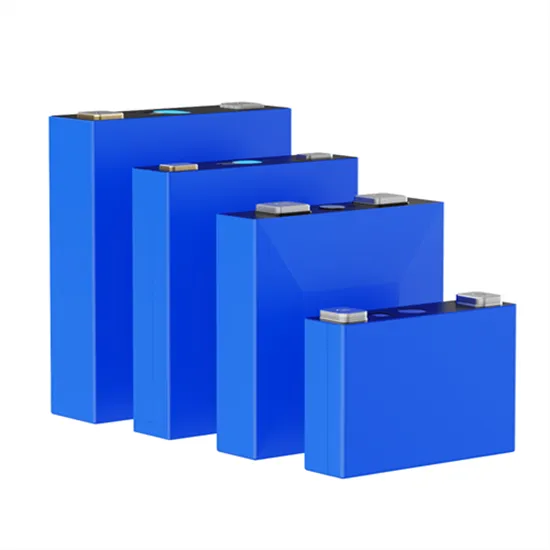

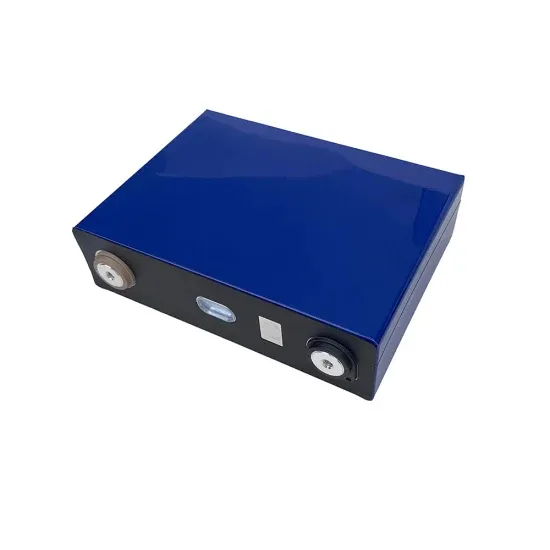

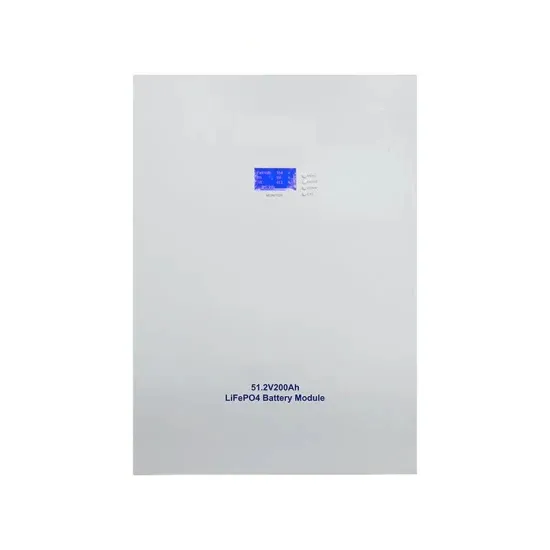

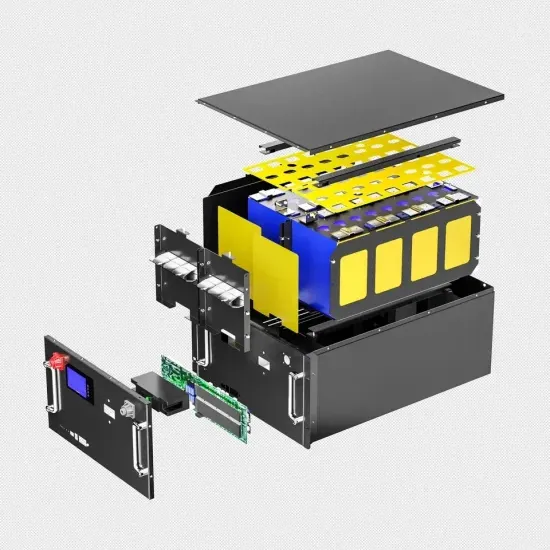

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.