Types of PV Panels – Solar Photovoltaic

There are two general types crystalline silicon photovoltaics, monocrystalline and multicrystalline, both of which are wafer-based. Monocrystalline

Get Started

Impact of Cracks in Multicrystalline Silicon Solar Cells on PV Module

Sep 8, 2015 · In this paper, we present a methodology to exploit the crack statistics of solar cells in photovoltaic (PV) modules assessed in field for simulating the power output of PV modules

Get Started

Luminescent down-shifting natural dyes to enhance photovoltaic

Aug 1, 2020 · The short wavelength photons (below 500 nm) of the solar spectrum are under-utilized in multicrystalline silicon (mc-Si) solar modules because of thei

Get Started

Life-cycle assessment of multi-crystalline photovoltaic (PV)

Jan 1, 2015 · Areas with higher solar radiation are more suitable for installing PV systems. This study performs a life-cycle assessment for a photovoltaic (PV) system with multi-crystalline

Get Started

Polycrystalline Solar Panel: Definition, How it

Aug 12, 2024 · Polycrystalline, multicrystalline, or poly solar panels are a type of photovoltaic (PV) panel used to generate electricity from sunlight. They are

Get Started

Life cycle assessment for a grid-connected multi-crystalline

Sep 20, 2021 · A first life cycle assessment study for the evaluation of a grid-connected photovoltaic system in Mexico was carried out from a cradle-to-grave perspective. The

Get Started

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The solar photovoltaics (PV) market has been booming to meet the global energy demand and to reduce the carbon emissions from energy production. Among all the PV

Get Started

Types of PV Panels – Solar Photovoltaic

Compared to monocrystalline silicon, multicrystalline silicon PV cell is moderately efficient with a market efficiency ranging from 11-14%, as a result, the cost of

Get Started

72 CELL 320–340W 0/+

Dec 14, 2017 · POSITIVE POWER TOLERANCE Founded in 1997, Trina Solar is the world''s leading comprehensive solutions provider for solar energy. We believe close cooperation with

Get Started

Multicrystalline silicon production – PV

2 days ago · Multicrystalline silicon (mc-Si) is silicon material with multiple grains of crystals with different orientation and shape. Mc-Si is often referred to

Get Started

What is a PV Module? Solar Power Basics Explained

Sep 29, 2024 · Unlock the power of sunlight with photovoltaic (PV) modules – the fundamental building blocks of solar energy systems. PV modules, also known

Get Started

Characterization of Multicrystalline Silicon Modules with

Sep 30, 2013 · We performed accelerated lifetime testing of multicrystalline silicon PV modules in 85°C/85% relative humidity (RH) and 45°C/30% RH while placing the active layer in either

Get Started

Multicrystalline Silicon Cell

2.1.2 Polycrystalline silicon (poly-Si) cells Poly-Si cells are also known as the multicrystalline (multi-Si) solar cells. Polycrystalline silicon is a material consisting of multiple small silicon

Get Started

Multicrystalline Solar Cells for PV Manufacturers

5 days ago · Our multicrystalline solar cells are made with best-in-class PV materials to help solar module manufacturers and solar suppliers enhance

Get Started

SOLAR PV MODULES

Dec 11, 2024 · SOLAR PV MODULES TIER-1 PV MODULES Mono PERC P-Type Tier-1 PV Modules NEW TOPCON N-TYPE *Brands and specifications are subject to change based

Get Started

Multicrystalline (Poly) Cell Solar Modules

10Wp to 280Wp- 36 and 72 Cell Solar Modules. Solar cells directly convert sunlight into electricity by means of the photovoltaic effect. This occurs when

Get Started

Datasheet

Jun 13, 2024 · Adani Solar" is the brand name for legal entity "Mundra Solar PV Ltd." having its registered office at "Adani House, Nr Mithakhali Six Roads, Navrangpura, Ahmedabad 380

Get Started

Silicon for photovoltaic applications

Oct 15, 2006 · Silicon is used in photovoltaics (PV) as the starting material for monocrystalline and multicrystalline wafers as well as for thin film silicon modules. More than 90% of the annual

Get Started

Monocrystalline vs Polycrystalline

Aug 12, 2024 · There are two main types of solar panels that dominate the market: monocrystalline panels and polycrystalline (multicrystalline) panels.

Get Started

Crystalline Silicon Solar Cell and Module Technology

Jan 1, 2018 · The aim of this chapter is to present and explain the basic issues relating to the construction and manufacturing of PV cells and modules from c-Si. This includes the basic

Get Started

DESERV Multi Crystalline Solar PV Panels

RenewSys is the first vertically integrated manufacturer of solar PV modules and its key components - Encapsulants, Backsheets, and Solar PV Cells. We

Get Started

Crystalline Silicon Solar Cell and Module Technology

Jan 1, 2018 · Since 1970, crystalline silicon (c-Si) has been the most important material for PV cell and module fabrication and today more than 90% of all PV modules are made from c-Si.

Get Started

Solar Multi-crystalline Module

Multi-crystalline solar modules consist of several PV cells, where each cell has silicon crystals. These crystals allow these cells to serve as semiconductors.

Get Started

Crystalline Silicon Solar Cells: State-of-the-Art

Jun 17, 2012 · The cost distribution of a crystalline silicon PV module is clearly dominated by material costs, especially by the costs of the silicon wafer.

Get Started

Crystalline Silicon Module

Crystalline silicon (c-Si) modules dominate the PV market with a 95% share [73]. The cells are available in multicrystalline (multi-Si) and mono-crystalline (mono-Si) variants, with mono-Si as

Get Started

Photovoltaic Module: Definition, Importance, Uses and Types

Jul 5, 2024 · A photovoltaic (PV) module is a unit comprised of PV cells that gather sunlight and turn it into energy. Each module contains multiple PV cells shielded by different materials

Get Started

An efficient CNN-based detector for photovoltaic module

Jan 1, 2024 · Many methods have been proposed for detecting defects in PV cells [9], among which electroluminescence (EL) imaging is a mature non-destructive, non-contact defect

Get Started

Life cycle assessment of multicrystalline silicon photovoltaic

Aug 1, 2016 · Energy crisis and environmental problems have increased the attention on solar power development and utilization. This study aims to identify the environmental effects

Get Started

Moisture induced degradation in field-aged multicrystalline

Moisture ingress is one of the key fault mechanisms responsible for photovoltaic (PV) devices degradation. Understanding moisture induced degradation (MID) mechanisms in field-aged PV

Get Started

Properties of polycrystalline silicon cell

Oct 26, 2018 · Applications of Polycrystalline Silicon 1. Photovoltaic Energy Polycrystalline silicon plays a crucial role in solar energy production,

Get Started

Indoor and Outdoor Characterizations of Photovoltaic Module

Jan 1, 2012 · This work describes the methodology, basic procedures and instrumental employed by our laboratory for the determination of photovoltaic module characteristics. According to this

Get Started

6 FAQs about [Solar multicrystalline photovoltaic modules]

Why should you choose a multicrystalline solar cell?

Our high-efficiency multicrystalline solar cells are trusted by PV manufacturers worldwide and are engineered to meet the evolving requirements of the solar photovoltaics industry. They are built using the best-in-class raw materials and are subject to strict quality control. Our multicrystalline PV cells deliver the following benefits:

What is the difference between monocrystalline and multicrystalline solar panels?

There are several differences between monocrystalline and multicrystalline solar panels. The main underlying difference between the two types relates to their cell structure. Monocrystalline panels are made from monocrystalline cells, which consist of a single, pure silicon crystal.

What is a monocrystalline c-Si solar cell?

Monocrystalline c-Si cells are single crystal silicon solar cells. Targray's monocrystalline c-Si cells are produced using best-in-class raw materials and subject to strict quality control. Mono PERC solar cells, a type of monocrystalline cells, have paved the way for significantly increased efficiency over standard monocrystalline cells.

What are the benefits of multicrystalline PV cells?

Our multicrystalline PV cells offer several benefits: They deliver high Cell-To-Module ratio through precise cell conversion efficiency sorting. These cells are classified efficiency grade by both minimum power and current. Additionally, they provide excellent electrical long-term stability and reliability. Built using the best-in-class raw materials and subject to strict quality control.

Why is LCA conducted on multi-crystalline silicon photovoltaic systems in China?

LCA is conducted on the multi-crystalline silicon photovoltaic systems in China. Multi-Si production is the most contributor to the energy demand and environmental impacts. Compared to other power generation systems in China, PV system is more environmentally friendly. Areas with higher solar radiation are more suitable for installing PV systems.

Is a photovoltaic (PV) system environmentally friendly?

Compared to other power generation systems in China, PV system is more environmentally friendly. Areas with higher solar radiation are more suitable for installing PV systems. This study performs a life-cycle assessment for a photovoltaic (PV) system with multi-crystalline silicon (multi-Si) modules in China.

Related Articles

-

Price per watt for solar photovoltaic modules

Price per watt for solar photovoltaic modules

-

Solar photovoltaic modules in the Netherlands

Solar photovoltaic modules in the Netherlands

-

Huawei Photovoltaic Solar Modules

Huawei Photovoltaic Solar Modules

-

Liechtenstein seaside solar photovoltaic panels

Liechtenstein seaside solar photovoltaic panels

-

New price of photovoltaic modules

New price of photovoltaic modules

-

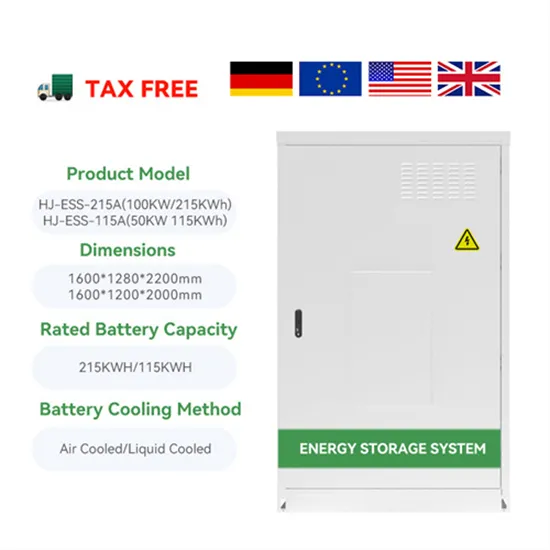

Solar Intelligent Energy Storage Cabinet Photovoltaic Electrical Prefabricated Cabin

Solar Intelligent Energy Storage Cabinet Photovoltaic Electrical Prefabricated Cabin

-

Monrovia Home Solar Photovoltaic Panels

Monrovia Home Solar Photovoltaic Panels

-

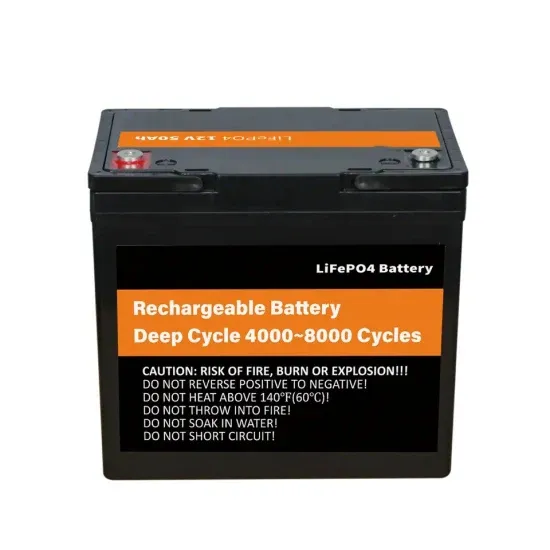

Solar Photovoltaic Inverter Lithium Iron Phosphate Battery

Solar Photovoltaic Inverter Lithium Iron Phosphate Battery

-

Photovoltaic solar panels in rural Saudi Arabia

Photovoltaic solar panels in rural Saudi Arabia

-

Off-grid solar photovoltaic panel 220v home complete set

Off-grid solar photovoltaic panel 220v home complete set

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

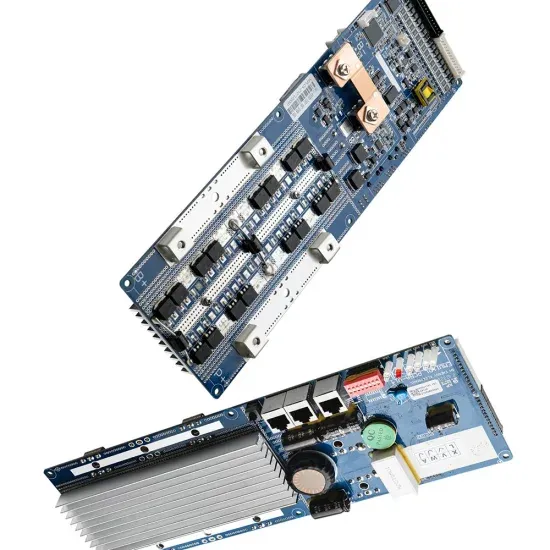

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.