Strings, Parallel Cells, and Parallel Strings

Feb 15, 2016 · Strings, Parallel Cells, and Parallel Strings Whenever possible, using a single string of lithium cells is usually the preferred configuration for a lithium ion battery pack as it is

Get Started

Battery Series and Parallel Connection Calculator

Jun 16, 2024 · Battery Series and Parallel Connection Calculator Battery Voltage (V): Battery Capacity (Ah): Number of Batteries: Calculate Linking multiple batteries either in series or

Get Started

Series Parallel Battery Pack Modules Trend in

Jul 20, 2023 · In 2024, more people are opting for parallel, series, and series-parallel lithium-ion battery pack designs for two primary reasons: 1) Batteries

Get Started

GenX Molicel+ 14.8V 4S7P 31500mah 13C Premium Lithium

This battery pack operates at a nominal voltage of 14.8V and is configured with 4 cells connected in series and 7 cells connected in parallel, which enhances both its voltage and capacity. With

Get Started

Battery configurations (series and parallel) and

Jun 26, 2023 · Sometimes, battery packs are used in both configurations together to get the desired voltage and high capacity. This configuration is found in the

Get Started

Assembly 14 series 7 parallel lithium battery pack

Fig. 7 (a) and Fig. 7 (b) show the voltage curves and the discharging capacities of the battery pack with parallel combination at different ambient temperature setups. As the temperature

Get Started

Can You Link Battery Packs? Understanding Series Vs. Parallel

Apr 11, 2025 · Yes, you can link battery packs safely. First, charge each pack fully. Use a voltmeter to check the voltage output. Ensure each pack outputs at least 21V (e.g., 5 packs at

Get Started

Modeling and Simulation of a Series and Parallel Battery

Apr 15, 2024 · Because lithium-ion movement within the battery is followed by charge flow in an external circuit, the efficiency of lithium-ion movement in the electrolyte impacts the battery

Get Started

Advantages of Customized Series-Parallel

Nov 12, 2024 · Why Custom Small Series-Parallel Lithium Battery Packs are in High Demand From consumer electronics to renewable energy, various

Get Started

Handbook On Lithium Battery Pack Design

Oct 30, 2023 · The environment in which the battery pack is used and the electrical connection of the individual cells (series or parallel) are two key considerations when designing a battery

Get Started

Examples of Battery Pack Configurations

May 25, 2025 · Series and Parallel When assembling large battery packs it is necessary to connect cells in series and parallel. Actually the normal method is to assemble them in parallel

Get Started

How many strings are 48V20AH lithium battery

Mar 3, 2021 · The whole set of batteries is 14 strings multiplied by 10 cells = 140 cells. Summary: Series and parallel have their own advantages for lithium iron

Get Started

Lithium battery series and parallel, the difference

Aug 1, 2025 · Lithium battery series and parallel: Both parallel combination and series combinations are in the middle of the battery pack, increasing the

Get Started

Definition of Series and Parallel Connection of

Oct 26, 2021 · Lithium batteries connected in series Add the voltage of batteries, capacity remains the same, and internal resistance increases. Lithium

Get Started

Introduction: What Is a Lithium-Ion Battery Pack?

Jul 4, 2025 · Lithium-ion battery packs are essential power sources used in medical equipment, drones, robots, and countless other devices. These packs are made of multiple Li-ion cells

Get Started

Examples of Battery Pack Configurations

May 25, 2025 · Battery pack designers are always being challenged to find a way of creating a flexible total pack design. Thus offering reusable building blocks

Get Started

Cells Per Battery Calculator

Nov 8, 2024 · The Cells Per Battery Calculator is a tool used to calculate the number of cells needed to create a battery pack with a specific voltage and

Get Started

Ultimate Guide of LiFePO4 Lithium Batteries in

Unlock the ultimate guide to using LiFePO4 lithium batteries in series and parallel. Learn configurations, benefits, and tips for optimal performance!

Get Started

Parallel then Series or Series then Parallel

Sep 29, 2023 · Parallel then Series This is the approach used in most passenger car electric vehicles and smaller battery pack designs.

Get Started

Cell Capacity and Pack Size

Jan 30, 2023 · Obviously Cell Capacity and Pack Size are linked. The total energy content in a battery pack in it''s simplest terms is: Energy (Wh) = S x P x Ah x

Get Started

Understanding Battery Pack Configurations: Series vs. Parallel

Feb 17, 2025 · Battery pack configurations determine how much power a battery can provide and for how long. Whether you''re choosing a battery pack for an electric vehicle, a robotics project,

Get Started

Series Parallel Battery Pack Modules Trend in

Jul 20, 2023 · Home » Blog » LiFePO4 » Series-Parallel Li-ion Battery Pack Modules Trend in 2024 As the world becomes more dependent on technology

Get Started

Lithium Ion Batteries in Series vs Parallel

May 2, 2020 · The Lithium-ion battery pack is the combination of series and parallel connections of the cell. In this blog batteries in series vs parallel we

Get Started

18650 Battery Pack Calculator

May 28, 2025 · This 18650 battery pack calculator is used to determine the optimal configuration of 18650 lithium-ion cells for a specific power requirement. With a 12V battery pack with 10Ah

Get Started

Understanding the Performance of Lithium

Mar 12, 2025 · While parallel connections focus on increasing capacity and runtime, series connections are designed to increase voltage for high-power

Get Started

What is Series Connection (S) in Lithium Battery

Jul 29, 2025 · Parallel Connection (P): Cells connected so all positives and all negatives are linked, increasing capacity—voltage stays the same. Battery Pack: An assembly of multiple

Get Started

Optimal fast charging strategy for series-parallel configured lithium

Jan 1, 2025 · Compared to the individual cell, fast charging of battery packs presents far more complexity due to the cell-to-cell variations [11], interconnect parallel or series resistance [12],

Get Started

Series, Parallel, and Series-Parallel Connections of Batteries

The number of batteries you can wire in series, parallel, or series-parallel depends on the specific application and the capabilities of the battery bank you are building. For details, refer to the

Get Started

How to Balance Lithium Batteries with Parallel

Sep 1, 2023 · A parallel BMS regulates the current flow between 2 or multiple batteries connected in parallel, learn how it works and how to connect it.

Get Started

Helpful Guide to Lithium Batteries in Parallel and

Apr 23, 2024 · Lithium battery series and parallel: There are both parallel and series combinations in the middle of the lithium battery pack, which increases

Get Started

14.8V 4S4P 13400mAh ICR18650 Battery Pack | PKCELL

Pkcell 14.8V 4S4P 13400mAh ICR18650 battery pack—customizable, high-capacity, safe and reliable. Ideal for e-bikes, tools, solar & storage. Contact us now!

Get Started

Battery pack calculator : Capacity, C-rating, ampere, charge

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

Get Started

Knowledge related to series parallel connection of lithium

Mar 22, 2022 · Lithium battery series parallel connection: There are both parallel and series combinations in the middle of the battery pack, which increases the voltage and capacity.

Get Started

Everything About Lithium Battery Series

May 21, 2025 · The series and parallel connection of lithium batteries is a key technology to increase voltage and capacity, but it also contains safety risks.

Get Started

6 FAQs about [14 series 7 parallel lithium battery pack]

Why is a lithium battery a series-parallel combination?

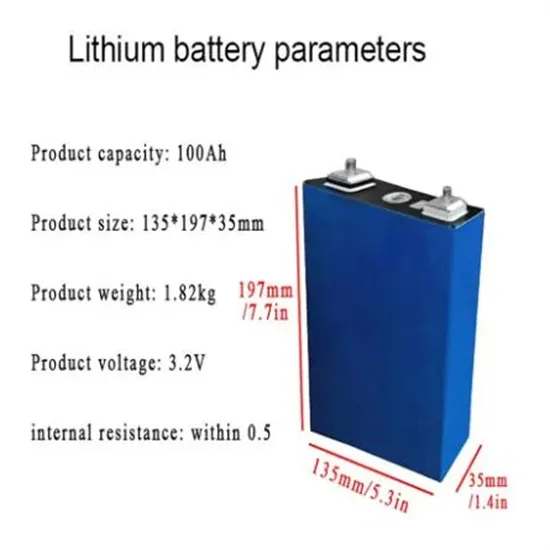

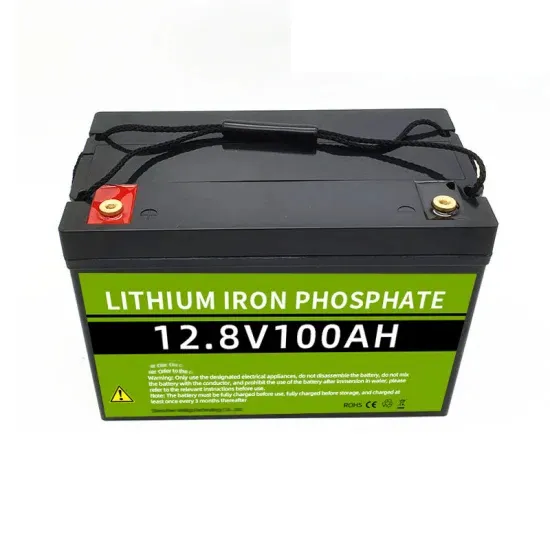

Due to the limited voltage and capacity of the single battery, in actual use, a series-parallel combination is required to obtain a higher voltage and ability to meet the existing power supply requirements of the equipment. Lithium batteries in series: the voltage is added, the capacity remains unchanged, and the internal resistance increases.

How to charge parallel lithium battery packs?

Specific principles must be followed when charging parallel lithium battery packs: Use a matching charger: The voltage must be suitable for the nominal voltage of the individual batteries. The current setting is reasonable: usually 0.2-0.5C of the total capacity after parallel connection.

Are series and parallel connection of lithium batteries safe?

The series and parallel connection of lithium batteries is a key technology to increase voltage and capacity, but it also contains safety risks. This article will analyze in detail the principles, methods and precautions of series and parallel connection of lithium batteries to help you avoid potential risks and build a battery system correctly.

How many volts can a 3.7V lithium battery get?

For example, 4 pieces of 3.7V lithium batteries connected in series can get an output voltage of 14.8V, but the capacity remains unchanged. Series connection is the most common method to make the battery pack reach the required operating voltage. Series connection is the best choice when you need more voltage rather than more capacity.

How to assemble a battery pack?

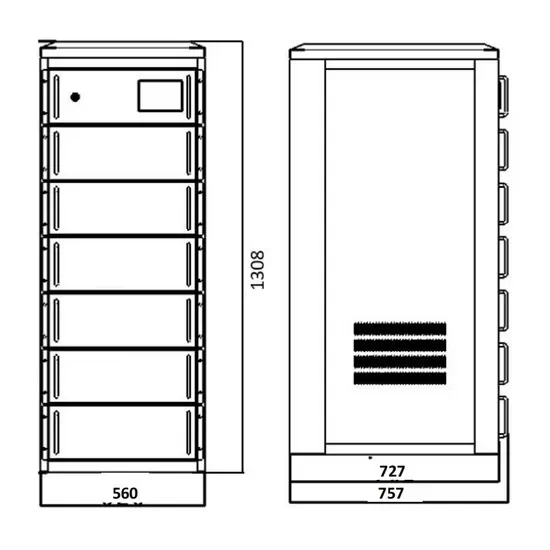

When assembling large battery packs it is necessary to connect cells in series and parallel. Actually the normal method is to assemble them in parallel groups and then to assemble these groups in series. Low Voltage (LV) packs that are below 60V which is the safe DC working limit. 2022 BTCC Hybrid Battery An extreme race car 48V MHEV battery pack.

What is an example of a battery pack configuration?

Examples of battery pack configurations, going up in total energy content down the page. Sort of as we have separated out the packs that are arranged as multiple packs in parallel, arranging them based on the size of the basic building block. Series and Parallel

Related Articles

-

14 8V lithium battery pack

14 8V lithium battery pack

-

How many amperes are there in a 12v lithium battery pack with 3 series and 8 parallels

How many amperes are there in a 12v lithium battery pack with 3 series and 8 parallels

-

Lithium battery pack series voltage is low

Lithium battery pack series voltage is low

-

12v lithium battery pack mobile power

12v lithium battery pack mobile power

-

60v50a lithium iron phosphate battery pack

60v50a lithium iron phosphate battery pack

-

Equatorial Guinea RV modified lithium battery pack

Equatorial Guinea RV modified lithium battery pack

-

Singapore RV lithium battery pack

Singapore RV lithium battery pack

-

Lithium battery pack field changes

Lithium battery pack field changes

-

16500 lithium battery pack

16500 lithium battery pack

-

Vilnius 26650 lithium battery pack

Vilnius 26650 lithium battery pack

Commercial & Industrial Solar Storage Market Growth

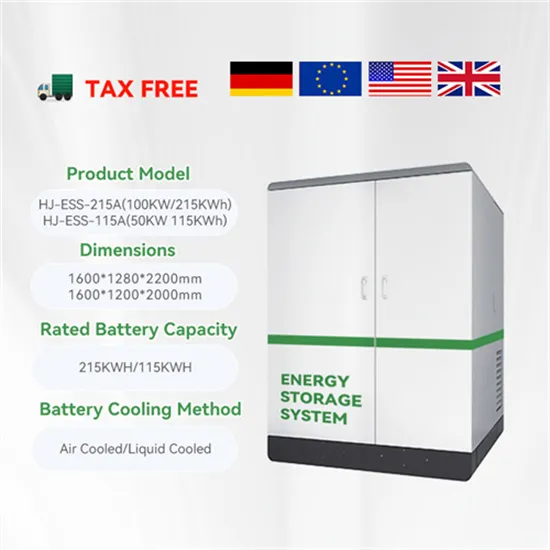

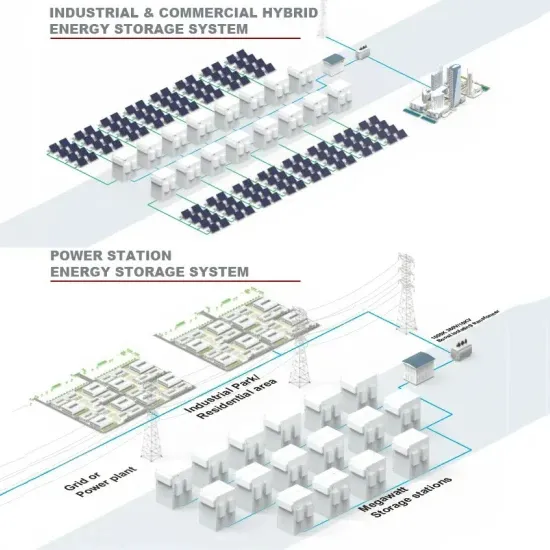

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

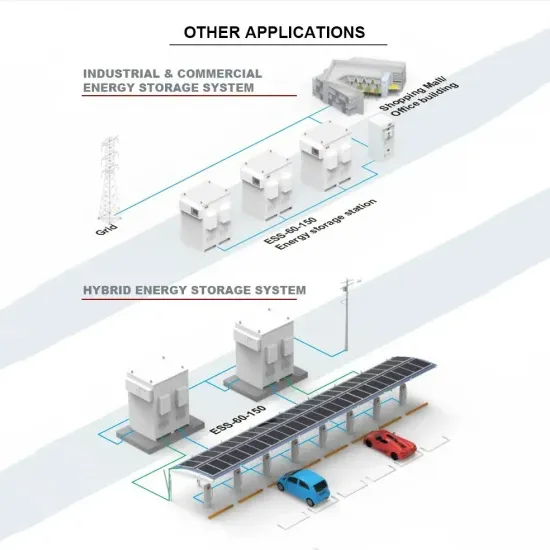

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.