Impacts of vibration and cycling on electrochemical

May 1, 2024 · The results indicate a significant decrease in stored electric energy within the battery after vibration. The direct current internal resistance of the battery shows a minor

Get Started

Portable Energy Storage _ Vehicle-Mounted

Jiangsu Senji New Energy Technology Co., Ltd. is a professional engaged in portable energy storage, vehicle-mounted battery, energy storage integrated

Get Started

Optimizing the Wire Harness for EV Battery Swapping Cabinets

Apr 19, 2024 · Introduction: Shanghai Futronics Electronic Technology Co., Ltd. is dedicated to offering comprehensive solutions for new energy vehicle connectors, industrial connectors,

Get Started

Energy storage cabinet

Energy Cabinet Huijue proudly presents its revolutionary Energy Cabinet, a pioneering energy storage solution that redefines industrial power backup and management. With its integration

Get Started

Advancements in Vibration Testing: Effects on Thermal

Aug 13, 2025 · Vibrations can cause structural issues, such as the separation of electrodes and the deformation of separators. These problems raise internal resistance and lead to localized

Get Started

What is an energy storage battery cabinet?

May 22, 2024 · A comprehensive examination of an energy storage battery cabinet reveals that it serves as a vital component in modern energy

Get Started

Quality Energy Storage Container & Energy

China leading provider of Energy Storage Container and Energy Storage Cabinet, Shanghai Younatural New Energy Co., Ltd. is Energy Storage Cabinet factory.

Get Started

Lightweight design and static strength analysis of battery

Sep 20, 2019 · Fengwu Shan, Dunhou Tan, Jing Lin (2008). Lightweight design of battery box cover for new energy electric vehicles based on Optistruct topology optimization. Times

Get Started

Battery Vibration: Everything You Need to Know to Avoid Battery

3 days ago · Nowadays, batteries play a crucial role in various sectors, ranging from electric vehicles to large-scale energy storage systems. However, behind their growing performance

Get Started

Expert 48V Lithium Battery Supplier

From breakthrough lithium materials chemistry to innovations in battery systems management and complete system design, Cloud Energy provides game

Get Started

Test cabinets for energy storage systems | CTS

6 days ago · Test cabinets and chambers for energy storage systems Safe test systems from CTS Environmental Simulations New drive systems such as

Get Started

The Ultimate Guide to Vibration Testing for EV

Sep 11, 2024 · Vibration Testing 101: The Ultimate Guide to Vibration Testing for EV Battery Packs According to the Ministry of Public Security, as of June

Get Started

Energy Storage Cabinets: Key Components,

Aug 12, 2024 · Energy storage cabinets are crucial in modern energy systems, offering versatile solutions for energy management, backup power, and

Get Started

BYD Energy

Aug 6, 2025 · Standard outdoor battery cabinet, MC Cube-T uses the new-generation LFP battery for energy storage, and adopts the world''s first CTS (Cell To System) integration technology,

Get Started

Battery – Green Building New Energy

BESS Cabinet 344 kWh Liquid-cooled battery storage system based on HiTHIUM prismatic LFP BESS Cells 280 Ah with high cyclic lifetime Improved safety characteristics and specially

Get Started

New energy battery high frequency electromagnetic vibration

New energy battery high frequency electromagnetic vibration testmachine 1 / 3 Pages Catalog excerpts New energy battery high frequency electromagnetic vibration test machine The

Get Started

储能柜冲击试验仿真和随机振动疲劳寿命研究

Dec 26, 2019 · 本文通过基于模态叠加法的瞬态分析法计算储能柜的冲击响应,以及基于随机振动响应下的1σ、2σ、3σ应力计算的振动疲劳寿命,对试验过程中的受力情况进行模拟,从而对试验结

Get Started

Energy storage battery cabinet vibration standard

GB/T36276-2018 "Lithium-ion batteries for electric energy storage": This standard applies to lithium-ion batteries used in electric energy storage. Including independent battery packs and

Get Started

Cell geometry influences on the vibration performance of

Feb 15, 2025 · Lithium-ion batteries are rechargeable energy storage systems in which lithium ions travel between negative and positive electrodes during charging and discharging [1]. In

Get Started

New Energy Battery Technology for Communication

Can energy storage battery technology be used in communication network cabinets . Lead-Acid Battery to Lithium Battery. An energy storage system with higher energy density is needed in

Get Started

How can vibration isolation techniques be implemented in battery

Jan 27, 2025 · Implementing vibration isolation techniques in battery storage systems is crucial to protect these sensitive components from external disturbances, which can degrade their

Get Started

Mechanical vibration modeling and characterization of a

Sep 1, 2022 · By analyzing the mechanical structure of the battery, the first principles modeling method is selected to model the battery''s mechanical performance. The vibration data in the

Get Started

Energy Storage System Basis: What Are Energy

An energy storage cabinet is a device that stores electrical energy and usually consists of a battery pack, a converter PCS, a control chip, and other

Get Started

How about new energy storage cabinet | NenPower

Jun 1, 2024 · 1. INNOVATIVE TECHNOLOGY The landscape of energy storage has witnessed a profound transformation, thanks in large part to the advent of new energy storage cabinets.

Get Started

Accuracy requirements for battery aging cabinets in battery

Jun 30, 2025 · Its business covers battery materials, battery pack manufacturing, research and development of intelligent battery testing equipment, battery cascading utilization testing,

Get Started

WEB-Guangdong Didu New Energy Co., Ltd

Company Profile DIPOWER is a technical expert in the new energy battery materials industry, focusing on the research and development, production, and application of new energy battery

Get Started

New Energy Ltd – Battery pack designer and

5 days ago · New Energy Ltd is a professional battery pack designer and manufacturer with more than 20 years of experience. We serve the industry in

Get Started

Comparative study of vibrational behaviour of lithium-ion batteries

Jun 1, 2025 · Abstract The impact of placement orientation on vibration-induced electrochemical degradation of three different lithium-ion battery geometries, namely, pouch, prismatic, and

Get Started

6 FAQs about [New Energy Battery Cabinet Vibration]

What is vibration testing of power battery systems?

Vibration testing is an essential method for assessing the mechanical reliability of power battery systems. This article primarily introducing the vibration testing methods of power battery systems. 1. Vibration Testing 2. Comparison of Battery System Vibration Standards 3. Vibration Testing of Power Battery Systems 1. Vibration Testing

How a power battery system is fixed to a vibration table?

Power battery systems are usually fixed to the vibration table using specially designed fixtures. The main function of the fixtures is to secure the sample to the table and transmit the vibration load from the table to the test sample without distortion.

What are the standards for vibration testing of battery systems?

Most testing standards for battery systems include vibration tests. The national mandatory standard GB38031 ⇱, issued in 2020, clearly defines the methods and requirements for vibration testing of power battery systems. The relevant standards for vibration testing of battery systems in both domestic and international contexts are as follows:

Why is vibration resistance important?

During vehicle operation, the power battery system is constantly subjected to vibration loads, making vibration resistance an important evaluation criterion. Vibration testing is an essential method for assessing the mechanical reliability of power battery systems.

What causes a battery to vibrate?

Vibration refers to the oscillatory motion of an object relative to its equilibrium position. It is generally characterized by functions such as displacement, velocity, and acceleration that change over time. The main sources of vibration for power battery systems include road surface irregularities and motor rotation imbalances.

How reliable is a power battery system?

The power battery system is the core component of electric vehicles, and its reliability directly affects the safety and reliability of the entire vehicle. During vehicle operation, the power battery system is constantly subjected to vibration loads, making vibration resistance an important evaluation criterion.

Related Articles

-

Kuwait New Energy Battery Cabinet Battery Cabinet Communication Power Supply

Kuwait New Energy Battery Cabinet Battery Cabinet Communication Power Supply

-

New energy battery cabinet for balancing

New energy battery cabinet for balancing

-

New Energy Battery Cabinet Company

New Energy Battery Cabinet Company

-

How many hours does it take to lift a battery cabinet for new energy

How many hours does it take to lift a battery cabinet for new energy

-

New technology of lithium battery for energy storage cabinet

New technology of lithium battery for energy storage cabinet

-

New energy battery cabinet data cleared

New energy battery cabinet data cleared

-

New energy battery cabinet photovoltaic water cooling

New energy battery cabinet photovoltaic water cooling

-

New energy battery cabinet helium inspection equipment

New energy battery cabinet helium inspection equipment

-

Canberra new energy battery cabinet cooling modification

Canberra new energy battery cabinet cooling modification

-

New Energy Battery Cabinet Safety Test

New Energy Battery Cabinet Safety Test

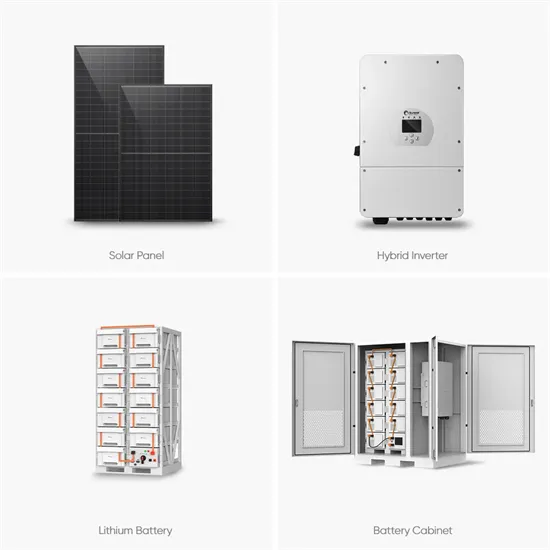

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.