What equipment is needed for solar power

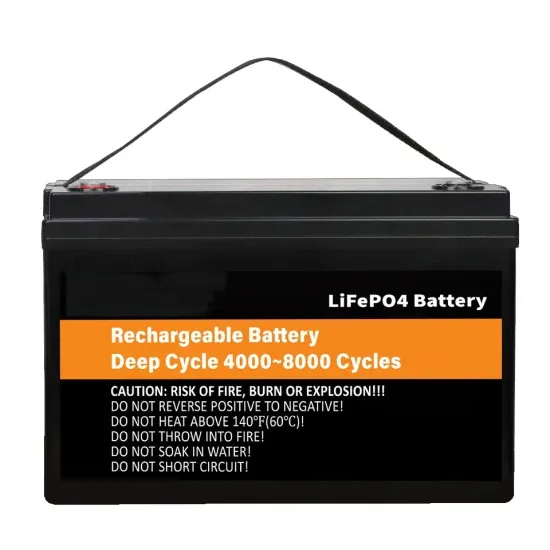

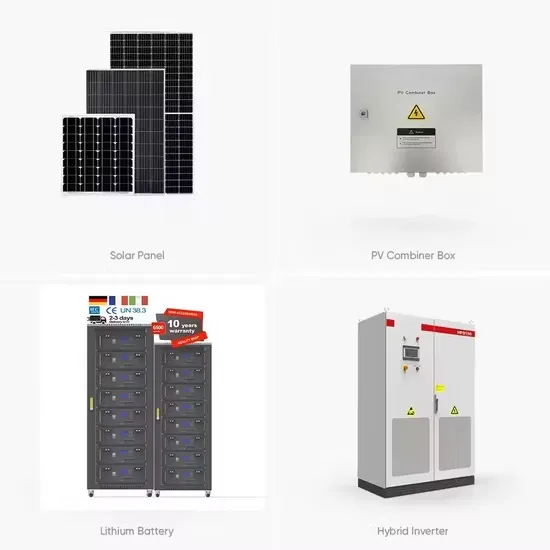

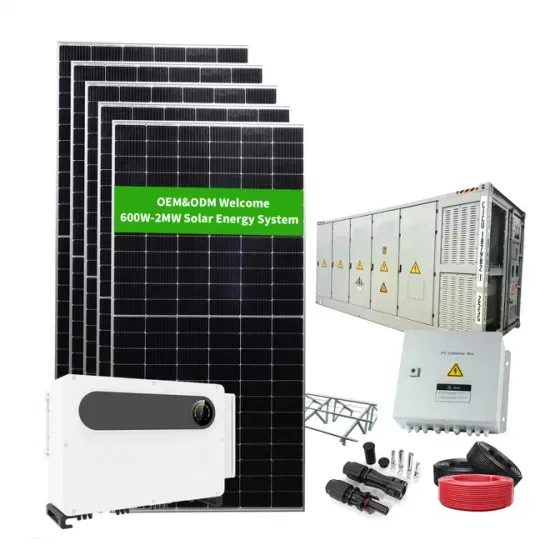

Jan 15, 2024 · To effectively set up a solar power generation system, 1. photovoltaic (PV) panels, 2. an inverter, 3. battery storage, 4. a charge

Get Started

What Equipment Is Needed For Solar Energy?

Feb 10, 2023 · Solar panels are essential for harnessing solar energy: They convert sunlight into electricity and are a crucial component of any solar

Get Started

Solar Power System Types: Equipment Needed,

Solar panels installed on rooftops take advantage of the sun''s energy and convert it into a usable energy source. Solar panels are sometimes called PV

Get Started

What machines are needed to make solar panels?

Solar panel manufacturing equipment encompasses a variety of specialized machines and tools used to produce photovoltaic (PV) panels. These machines handle tasks like cutting materials,

Get Started

Solar Panel Manufacturing Plant Costs: 6 Crucial

Feb 2, 2023 · Do you want to start a solar panel manufacturing factory and you need an in-depth solar panel manufacturing plant cost breakdown? If yes, then

Get Started

What equipment is used to make photovoltaic panels

Dec 1, 2020 · The Equipment You Need For A Solar Panel System You need solar panels, inverters, racking equipment, and performance monitoring equipment to go solar. You also

Get Started

Basics of Solar Panel Manufacturing | Step-by

Jan 20, 2023 · The production of quality solar panels is a complex process involving many steps and components. In this guide, we will walk you through

Get Started

What equipment is used to make photovoltaic panels

Dec 1, 2020 · As the photovoltaic (PV) industry continues to evolve, advancements in What equipment is used to make photovoltaic panels have become critical to optimizing the

Get Started

Types of solar equipment, explained | Essentra Components US

Oct 1, 2021 · What is the process of harnessing solar energy? Knowing that will help with understanding solar energy systems and the solar power equipment needed. We''ll explain as

Get Started

What equipment is used in the production of

What equipment do you need to make solar panels? lator. Accessories: Laboratory accessories for quality control. Setting a production line f solar panels is a task that requires know What

Get Started

Solar PV Installation Essentials: A Guide To Tools And Equipment

Dec 2, 2024 · When it comes to solar photovoltaic (PV) installation, having a good understanding of the tools and equipment needed is essential. From the initial design and planning stages to

Get Started

How to Build Your Own DIY Solar System

Dec 15, 2020 · Better yet, the cost of materials needed for home solar has plummeted in the last decade by 70%. The biggest reason for the price drop

Get Started

21 Essential Tools You Need for Solar Panel

May 15, 2024 · This guide provides a comprehensive list of the 21 essential tools needed for every stage of a solar panel installation, from initial inspection to

Get Started

What equipment is needed to install solar energy

Here''''s a list of our recommended equipment needed for a complete solar power system setup. If you want a different setup variation, see our other articles to help with determining what

Get Started

Solar Panel Making Machines: 14 Tips to Boost Efficiency

Mar 25, 2023 · Unlock 14 proven insights into solar panel making machines. Learn how to streamline production, reduce costs, and achieve maximum efficiency in solar manufacturing.

Get Started

What equipment is needed to make photovoltaic panels

Discover the latest Solar panels'' production & testing machines from Ecoprogetti Srl by clicking Solar panel production equipment and machinery Nowadays the solar panels'' production

Get Started

A Comprehensive Guide to Solar Panel

Established in 2017, Sunway Solar is a leading solar panel manufacturer and one of the most trusted global suppliers of solar panels today. The brand provides

Get Started

Solar Panel Manufacturing: A Comprehensive

Aug 9, 2023 · Solar panel manufacturing is the process of producing photovoltaic (PV) panels used to capture energy from the sun and convert it into usable

Get Started

Solar panel production equipment and machinery

Oct 28, 2016 · Nowadays the solar panels'' production equipment is divided into the following required machinery and accessories. The first run automated processes are the stringing and

Get Started

What Components Do You Need for Solar Panel

Oct 20, 2019 · Solar Panel System Solar panel (also known as photovoltaic cell or solar cell) is a device which absorbs photos from the sun light and converts to

Get Started

Solar Photovoltaic Manufacturing Basics

4 days ago · Solar manufacturing encompasses the production of products and materials across the solar value chain. This page provides background

Get Started

Solar Energy Equipment

Dec 31, 2024 · Among the solar equipment, we also find several of the key components, such as solar panels, inverters, and racking systems. Solar Panels Solar panels are the components

Get Started

Solar Panel Manufacturing Process: Step-by-Step Guide

Apr 12, 2025 · Solar energy has gained immense popularity globally as a clean and sustainable energy source. Solar panels, also known as photovoltaic (PV) panels, are essential to

Get Started

Solar Photovoltaic Panel Production Equipment

The Photovoltaic Panel. In a system for generating electricity from the sun, the key element is the photovoltaic panel, since it is the one that physically converts solar energy

Get Started

Solar Power System Equipment: Needs, Costs,

What is a solar panel system? A roof-mounted solar panels system absorbs and converts the energy-packed photons of natural sunlight into a usable energy

Get Started

PV Solar Cell Manufacturing Process

Silicon Ingot and Wafer Manufacturing Tools: These transform raw silicon into crystalline ingots and then slice them into thin wafers, forming the substrate of

Get Started

What Equipment You Need for a Complete Solar

While getting started with solar electricity is more complicated than simply purchasing a set of solar panels, once you know what pieces of equipment

Get Started

Best 6 Solar Energy Equipment: A Complete

As the world shifts toward renewable energy, solar energy equipment plays a critical role in harnessing the power of the sun. From photovoltaic (PV) panels

Get Started

Things Needed To Set Up A Solar Power For

Jun 20, 2025 · Bottom-up: Solar energy is one of the best resources for producing energy. Solar panels are the major component that converts the energy of the

Get Started

6 FAQs about [What equipment is needed to make photovoltaic panels]

What equipment do you need to make solar panels?

Main machinery: Solar simulator. Accessories: Laboratory accessories for quality control. Setting a production line of solar panels is a task that requires know-how and experience.

What equipment is used to make solar cells?

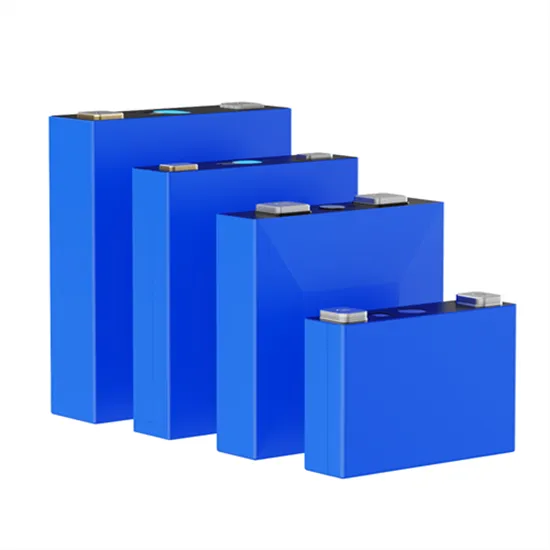

Silicon Ingot and Wafer Manufacturing Tools: These transform raw silicon into crystalline ingots and then slice them into thin wafers, forming the substrate of the solar cells. Doping Equipment: This equipment introduces specific impurities into the silicon wafers to create the p-n junctions, essential for generating an electric field.

Where can I find the latest solar panels production & testing machines?

Discover the latest Solar panels’ production & testing machines from Ecoprogetti Srl by clicking here. Solar panel production equipment and machinery Nowadays the solar panels’ production equipment is divided into the following required machinery and accessories.

How are solar panels manufactured?

Nowadays the solar panels’ production equipment is divided into the following required machinery and accessories. The first run automated processes are the stringing and lamination, but also the analysis of quality as electroluminescence tests. These and other procedures are indispensable for the correct manufacture of the module in each component.

How are PV solar cells made?

The manufacturing process of PV solar cells necessitates specialized equipment, each contributing significantly to the final product’s quality and efficiency: Silicon Ingot and Wafer Manufacturing Tools: These transform raw silicon into crystalline ingots and then slice them into thin wafers, forming the substrate of the solar cells.

What is a photovoltaic (PV) solar cell?

Central to this solar revolution are Photovoltaic (PV) solar cells, experiencing a meteoric rise in both demand and importance. For professionals in the field, a deep understanding of the manufacturing process of these cells is more than just theoretical knowledge.

Related Articles

-

What is the role of photovoltaic panels on the roof

What is the role of photovoltaic panels on the roof

-

What is the maximum power of 182 type photovoltaic panels

What is the maximum power of 182 type photovoltaic panels

-

What is the standard size of rural photovoltaic panels

What is the standard size of rural photovoltaic panels

-

What are the models of 300mw photovoltaic energy storage equipment

What are the models of 300mw photovoltaic energy storage equipment

-

Tonga will make photovoltaic panels

Tonga will make photovoltaic panels

-

What is the appropriate power for photovoltaic panels for personal use

What is the appropriate power for photovoltaic panels for personal use

-

How many solar panels are needed for 5kw photovoltaic power generation

How many solar panels are needed for 5kw photovoltaic power generation

-

How many solar panels are needed for a 10kw photovoltaic installation

How many solar panels are needed for a 10kw photovoltaic installation

-

What size are the photovoltaic panels installed in rural areas

What size are the photovoltaic panels installed in rural areas

-

What is the series voltage of 24v photovoltaic panels

What is the series voltage of 24v photovoltaic panels

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.