Ultra thin silicon wafer slicing using wire-EDM for solar cell

Jun 15, 2017 · The ever increasing demand of silicon solar cells in PV industry calls for minimizing the material loses (kerf) during Si wafer slicing. The currently employed abrasive slicing

Get Started

Communication base station solar photovoltaic silicon

The other two newly emerged stars also achieved record-high growth with prominent profits despite comparatively lower volumes. Currently,most of the world''s silicon wafer production

Get Started

Photovoltaic Cutting Solutions-Gaoce Technology

In addition, we can provide automatic production lines including cropping, squaring, grinding, cutting, gluing, and packaging of silicon wafer; we can

Get Started

How Silicon Wafer Solar Cells Are

May 16, 2024 · Explore the impact of silicon wafer solar cells on the solar industry and their role in advancing clean energy solutions in India.

Get Started

Gstar Breaks Ground on Advanced Silicon Rod

May 3, 2024 · Discover how Gstar''s groundbreaking ceremony heralds the dawn of a cutting-edge silicon rod and wafer factory in Jakarta, Indonesia. Explore

Get Started

Monocrystalline Silicon Wafers

Monocrystalline silicon wafers are thin slices of silicon crystals that are used as the base material in the manufacturing of various electronic devices,

Get Started

The solar cell wafering process

May 21, 2024 · The multi-wire sawing technique used to manufacture wafers for crystalline silicon solar cells, with the reduction of kerf loss currently representing about 50% of the silicon,

Get Started

CHINT''s Thai Base Hits Milestone with Silicon Wafer Project

Apr 25, 2024 · In May of last year, CHINT Astronergy''s Thailand base celebrated the rollout of its first solar cells and modules during the completion of Phase 2.5. This April 15th, the factory

Get Started

How to slice solar silicon wafers | NenPower

Oct 11, 2024 · Solar silicon wafers are essential components in photovoltaic cells, converting sunlight into electricity. The manufacture of these wafers begins

Get Started

Photovoltaic Silicon Wafers

Apr 17, 2024 · In June 2020, seven companies including Longi, Jinko, and JA Solar jointly advocated the establishment of the M10 (182mm) photovoltaic

Get Started

Technology and Power Company Gstar Begins Construction of Silicon Wafer

The factory''s main products are monocrystalline silicon rods and large-sized silicon wafers, specifically 182mm and 210mm, which hold significant potential in the solar photovoltaic

Get Started

The solar cell wafering process

May 21, 2024 · AbstrAct The process of wafering silicon bricks represents about 22% of the entire production cost of crystalline silicon solar cells. In this paper, the basic principles and

Get Started

How Solar Silicon Wafers Are Made into Cells

Jan 9, 2024 · How Solar Silicon Wafers Are Made into Cells The process of transforming solar silicon wafers into cells involves several meticulous steps,

Get Started

About Astronergy | A Pioneer in n-type TOPCon

Committed to being the most competitive photovoltaic module supplier worldwide, Astronergy sets its mission to create a sustainable and net-zero carbon world

Get Started

Photovoltaic silicon panel slicing factory

Are solar PV modules made in a factory? While most solar PV module companies are nothing more than assemblers of ready solar cells bought from various suppliers,some factorieshave

Get Started

Review of monocrystalline silicon slicing technology

Aug 1, 2020 · Slicing of monocrystalline silicon is an important process in integrated circuit industry and photovoltaic industry, where the slicing method and qualities directly affect the

Get Started

Gstar Breaks Ground on Advanced Silicon Rod and Wafer Factory

May 3, 2024 · Discover how Gstar''s groundbreaking ceremony heralds the dawn of a cutting-edge silicon rod and wafer factory in Jakarta, Indonesia. Explore the strategic significance,

Get Started

Silicon Wafer Manufacturing Process: Sand to

Jul 24, 2025 · Silicon wafer is the foundation of all modern semiconductor manufacturing. It is the base, heart and backbone of all semiconductors and

Get Started

Diamond Wire Sawing of Solar Silicon Wafers: A Sustainable

Jan 1, 2018 · Slicing silicon wafers for solar cells and micro-electronic applications by diamond wire sawing has emerged as a sustainable manufacturing process with higher productivity,

Get Started

Gstar Announced the Strategic Move:

JAKARTA, Indonesia, April 29, 2024 /PRNewswire/ -- Recently, Gstar held a groundbreaking ceremony for its silicon rod and silicon wafer factory, marking

Get Started

Solar Cell Production: from silicon wafer to cell

Aug 17, 2023 · This article explains in detail the production process from sliced silicon wafer disks to the final ready-to-assemble solar cell.

Get Started

PV-Manufacturing – The free online resource

Silicon photovoltaic modules comprise ~90% of the photovoltaic modules manufactured and sold worldwide. This online textbook provides an

Get Started

Fabricating Different Types of Photovoltaic Cells

Jun 2, 2021 · A wafer is a thin, flat disk or rectangle of base semiconductor material. Wafers are 180μm to 350μm thick and are made from p-type silicon.

Get Started

Home Page

May 7, 2025 · Sunwafe focuses on ingot and wafer manufacturing, a critical stage in the photovoltaic value chain, where high-purity silicon is processed into thin

Get Started

Jingsheng Electromechanical

JSG Precision Equipment has developed crystal slicing machines for three major fields: photovoltaic silicon, semiconductor silicon, and sapphire. These machines are designed to

Get Started

Silicon Wafer Cutting Service -Gaoce Technology

Photovoltaic large silicon wafer R&D center and intelligent manufacturing demonstration base project have been completed. Leshan 20GW photovoltaic large silicon wafers and supporting

Get Started

What Is a Silicon Wafer for Solar Cells?

A wafer-based solar cell is a unique type of non-mechanical semiconductor that uses a p-n junction to produce the photovoltaic effect — transforming photons

Get Started

Photovoltaic silicon panel slicing factory

Diamond slicing is the main silicon wafer slicing technology in which highhardness diamonds on steel wire are used to slice silicon into thin sheets by high-speed

Get Started

Detailed explanation of silicon wafer cutting technology for solar

Dec 20, 2023 · Wafer cutting is a key part of the solar photovoltaic cell manufacturing process. This process is used to treat solid silicon ingots of monocrystalline or polycrystalline silicon.

Get Started

Gstar to build silicon wafer factory in Indonesia

May 6, 2024 · Gstar Solar recently held a groundbreaking ceremony for its silicon rod and silicon wafer factory in Jakarta, Indonesia. This move not only signifies a significant breakthrough for

Get Started

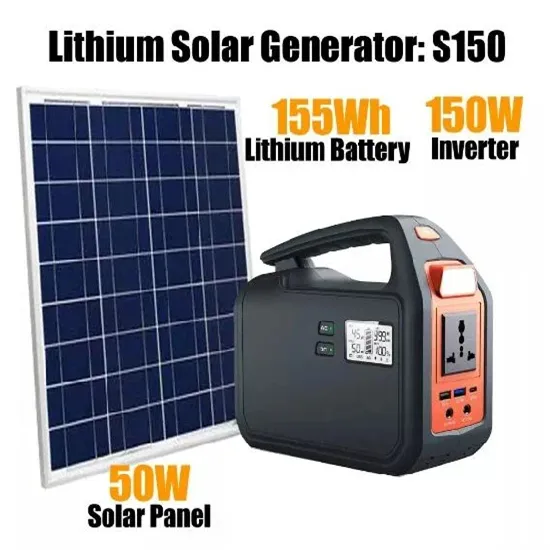

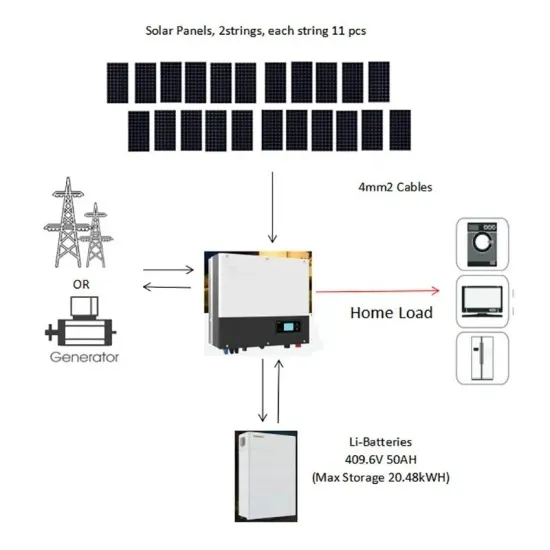

Telecom Base Station PV Power Generation System

Feb 1, 2024 · The communication base station installs solar panels outdoors, and adds MPPT solar controllers and other equipment in the computer room. The power generated by solar

Get Started

Silicon Wafer Cutting Equipment: The Core Engine of Solar

6 days ago · Explore how silicon wafer cutting equipment (wire saw) drives solar cell production. From wafer quality and cost control to fine wire sawing technology and automation, uncover its

Get Started

Photovoltaic panel silicon wafer cutting process

1. Silicon wafer cutting, material preparation: The monocrystalline silicon material used for industrial production of silicon cells generally adopts the solar grade

Get Started

Tungsten wire diamond line''s permeability improved,

Mar 22, 2024 · Diamond wire is an important consumable in the photovoltaic silicon wafer manufacturing process. Electroplated diamond wire is currently used for cutting hard and

Get Started

Gstar working on 3 GW silicon wafer factory in

Apr 30, 2024 · Singapore-based Gstar Solar says it has broken ground on a new 3 GW silicon wafer factory in Indonesia, with production scheduled to start by

Get Started

6 FAQs about [Communication base station solar photovoltaic silicon wafer slicing factory]

How is a silicon wafer made?

The process begins with silicon purification, where raw silicon is refined to remove impurities. The purified silicon is then melted and formed into ingots. Once the ingots are formed, they undergo slicing using diamond wire saws to create thin wafers, typically 150–200 micrometers thick.

How are silicon wafers cut?

The wafers are cut from silicon ingots using the wire sawing process (see Figure 1), which is an expensive step in the solar cell manufacturing process. Recent industry trends indicate a shift from the loose abrasive slurry (LAS) sawing to fixed abrasive diamond wire sawing (DWS) process for slicing silicon wafers [2, 3].

Can wire sawing produce crystalline wafers for solar cells?

Wire sawing will remain the dominant method of producing crystalline wafers for solar cells, at least for the near future. Recent research efforts have kept their focus on reducing the wafer thickness and kerf, with both approaches aiming to produce the same amount of solar cells with less silicon material usage.

Can thin silicon wafers be made with increased mechanical strength?

Hence, there is a critical need to address the problem of manufacturing thin silicon wafers with increased mechanical strength. The wafers are cut from silicon ingots using the wire sawing process (see Figure 1), which is an expensive step in the solar cell manufacturing process.

Why is wafering important for solar cells?

Another relevant field of research is the reduction of the wafer thickness in order to produce more wafers per kilogram silicon. Finally, the wafering process step, in combination with the material quality, defines the mechanical properties of the final solar cell, as the wafering process can damage the wafer’s surface.

Why do we need a silicon wafer substrate?

With low damage depth in sliced wafers, less material usage due to reduced kerf-loss, and the use of less toxic water-based cutting fluids, DWS can produce large area, high- strength silicon wafer substrates to meet the demands of society for cleaner and renewable photovoltaic energy.

Related Articles

-

Communication base station new energy factory solar photovoltaic panels

Communication base station new energy factory solar photovoltaic panels

-

Communication base station lithium battery solar factory

Communication base station lithium battery solar factory

-

ASEAN communication base station wind and solar complementary equipment room

ASEAN communication base station wind and solar complementary equipment room

-

Communication base station wind and solar complementary stocks

Communication base station wind and solar complementary stocks

-

North Africa nighttime communication base station solar panels

North Africa nighttime communication base station solar panels

-

Budapest Photovoltaic Energy Storage Cabinet Battery Factory Products Base Station

Budapest Photovoltaic Energy Storage Cabinet Battery Factory Products Base Station

-

Communication base station dual-purpose solar energy production price

Communication base station dual-purpose solar energy production price

-

Replacement of communication base station wind and solar complementary process

Replacement of communication base station wind and solar complementary process

-

What are the systems of communication base station inverter grid-connected photovoltaic power generation

What are the systems of communication base station inverter grid-connected photovoltaic power generation

-

Huawei 6g communication base station wind and solar complementary 125kWh

Huawei 6g communication base station wind and solar complementary 125kWh

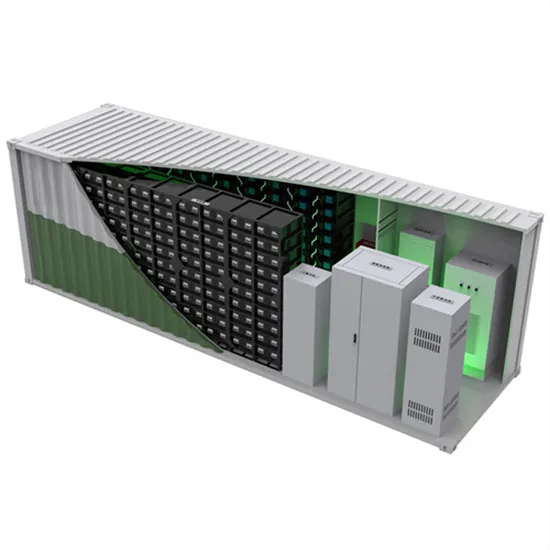

Commercial & Industrial Solar Storage Market Growth

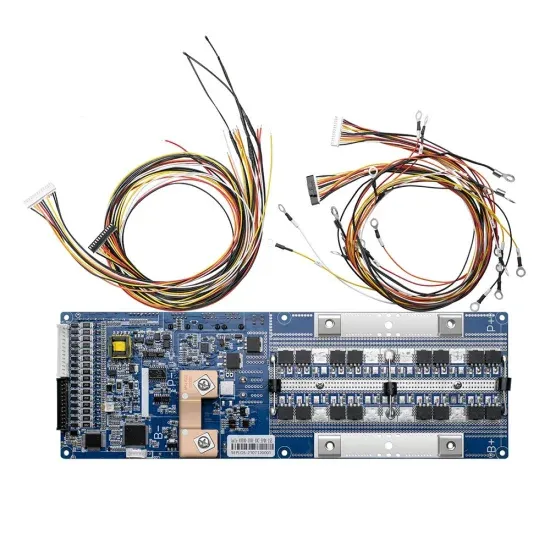

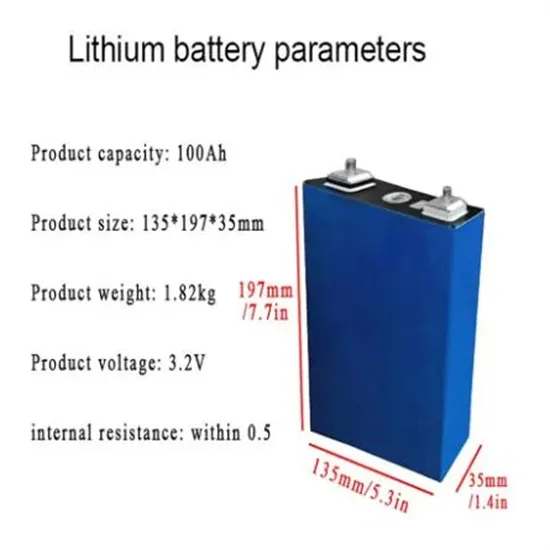

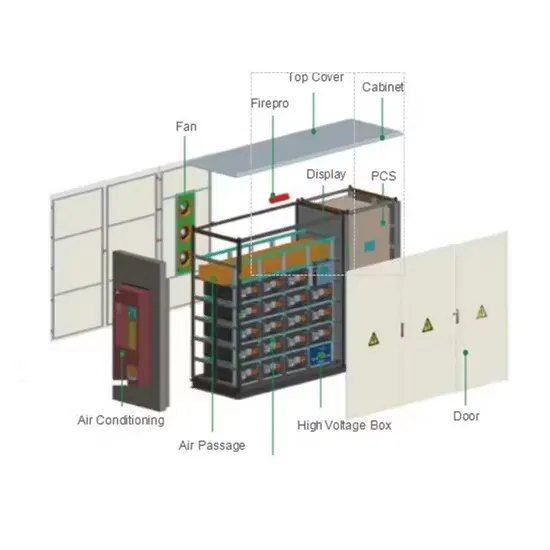

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.