Rock mechanical problems and optimization for the long

Dec 25, 2011 · Electricity is generated through four 16.67 km-long diversion tunnels, which cut the 150 km-long river bend. The project consists of 7 deep parallel tunnels, i.e. 4 diversion tunnels,

Get Started

CN108385627A

The present invention provides the power station diversion tunnel plugging construction methods based on karst landform, it includes the following steps:S1:It designs diversion tunnel and

Get Started

Left Diversion Tunnel of N-J Hydropower Project in Pakistan

Oct 25, 2016 · The diversion tunnel of N-J Hydropower Station will be 67 km long in accordance with the construction plan, a super long tunnel which can rarely be seen in the world.

Get Started

A Technical Review of Hydro-Project Development in China

Sep 1, 2016 · This paper summarizes the development of hydro-projects in China, blended with an international perspective. It expounds major technical progress toward ensuring the safe

Get Started

Broadlands Hydro Power Project (35 MW)

Aug 4, 2025 · The main sites of the project are located near Kithulgala. The main components included in the projects are the main dam, diversion dam, main

Get Started

DIVERSION TUNNEL STRUCTURAL INSPECTION AND

Mar 30, 2020 · The diversion-generating system consists of 4 inlets, four high-pressure diversion tunnels, one underground powerhouse, one switch station, two tailrace surge chambers and

Get Started

A Review of the Transient Process and Control

The hydropower station contains the following subsystems: Upstream reservoir, headrace tunnel, surge tank, penstock, tailwater, hydro-turbine, unit (including

Get Started

Study on Structure Design of Generator of Flood

Jan 1, 2021 · Abstract Through the design of the Generator of the spillway tunnel, the safe operation efficiency of flood discharge tunnel with the level swirling

Get Started

Exhaust structure of water diversion system of hydropower station

A technology for water diversion system and hydropower station, which is applied in the direction of hydropower station, hydropower generation, water conservancy project, etc., can solve

Get Started

(PDF) Diversion Tunnel Structural Inspection and

PDF | On Sep 1, 2019, HAORAN WANG and others published Diversion Tunnel Structural Inspection and Assessment Using a Robotic System | Find, read

Get Started

Key technologies and risk management of deep tunnel

Aug 1, 2016 · This hydropower station is a low-gate, long-tunnel, and large-capacity diversion-type power station with a total installed capacity of 4800 MW. The total excavation volume of the

Get Started

Power China signed the Bolivian Hydropower Station Diversion Tunnel

[Power China signed the Bolivian Hydropower Station Diversion Tunnel Project]On July 9, 2021, the 11th Bureau of Hydropower won the bid for the 2 package project of the diversion tunnel of

Get Started

Construction schedule simulation of a diversion tunnel based

Jun 15, 2009 · The construction of a diversion tunnel in power stations is highly mechanized and complicated, requiring a series of working procedures such as drilling, blasting, loading slag,

Get Started

Key principles for hydropower tunnel design, construction

Hydropower tunnels continue to represent the highest risk and critical path component for most hydropower projects. The increasing focus on hydropower as a major source of renewable

Get Started

Diversion Tunnel of Hydropower Projects for

The use of diversion tunnel to deal with this problem is discussed in this paper with the help of a case study conducted at Central Water and Power Research

Get Started

CN204919504U

The utility model discloses a power station diversion tunnel cave line arrangement structure belongs to hydraulic and hydroelectric engineering technical field, including river course,

Get Started

Mechanical characteristics of diversion and spillway

May 27, 2022 · Taking the diversion and spillway tunnel of a pumped storage power station under high in-situ stress as the research object, using finite diference method, the model of the

Get Started

Water diversion and power generation system of

Download scientific diagram | Water diversion and power generation system of hydropower station with upstream surge tank and sloping ceiling tailrace

Get Started

Photovoltaic generator model for power system dynamic studies

Nov 1, 2020 · This paper reviews the state-of-the-art PV generator dynamic modeling work, with a focus on the modeling principles of PV generator for the power system dynamic studies.

Get Started

Over 17,000 Metres of Diversion Tunnel Excavated for

Sep 22, 2023 · On September 12th, Chuosijia Hydroelectric Power Station, operated by Sichuan Power Generation Co., LTD under China Energy,achieved a breakthrough in the excavation

Get Started

Feasibility of Diversion Tunnel for Sediment Management in

Mar 2, 2025 · A diversion tunnel is also important in the case of hydropower projects in the Himalayan region, where reservoirs have a high suspended sediment load. If not addressed,

Get Started

DIVERSION TUNNEL STRUCTURAL INSPECTION AND

Mar 30, 2020 · Hydraulic tunnels are large-scale constructs used for water supply project, flood control project, and water diversion in the hydropower generation projects. It can be seen an

Get Started

Schematic diagram of layout of diversion power

The hydropower station diversion tunnel is long. When the upstream water level is low, the minimum upsurge of the surge chamber is likely to be lower than its

Get Started

Ambient Vibration Analysis of Diversion Pipeline in

Mar 12, 2024 · Vibrations within the vicinity of both the plant and the diversion pipeline are generated throughout the running phase of a pumped-storage power station due to its inherent

Get Started

Power Plant Components

The vertical diversion type structures are widely used in the small mountain brooks and rills either to directly feed power stations or to collect water for reservoirs from neighbouring drainage

Get Started

Olmsted Hydroelectric Power Plant

The Olmsted Hydroelectric Power Plant located at the mouth of Provo Canyon in Utah County, Utah is one of the oldest hydro power generation facilities in the

Get Started

Calculation and analysis of diversion tunnel structure based

Based on ansys for simulation calculations, first we simulate the force of the diversion tunnel under different working conditions; then we analyze the stress distribution in the stress cloud

Get Started

Key problems in the design of diversion tunnel in Jinping II

The construction of 4 diversion tunnels in Jinping II Hydropower Station is currently China''s deepest underground engineering project. The general depth is 1500–2000 m, and the

Get Started

Short-term load distribution model for giant cascade serial diversion

Sep 1, 2024 · With the development of complex cascade serial diversion-type hydropower plants (CSDHP) in Southwest China, it has become imperative to study short-term scheduling

Get Started

Layout of the diversion tunnel in the Yangjiang pumped-storage power

Due to high water pressure in the concrete reinforced hydraulic tunnels, surrounding rocks are confronted with nonlinear seepage problem in the pumped storage power station. In this study,

Get Started

Key technologies and risk management of deep tunnel

Aug 1, 2016 · The four diversion tunnels at Jinping II hydropower station represent the deepest underground project yet conducted in China, with an overburden depth of 1500–2000 m and a

Get Started

6 FAQs about [Diversion tunnel for photovoltaic power station generator set]

How many diversion tunnels are there?

Electricity is generated through four 16.67 km-long diversion tunnels, which cut the 150 km-long river bend. The project consists of 7 deep parallel tunnels, i.e. 4 diversion tunnels, 2 auxiliary tunnels, and 1 drainage tunnel. From south to north, there are auxiliary tunnels A and B, drainage tunnel, diversion tunnels #4, #3, #2 and #1.

How can diversion tunnels be used to generate electricity a year in advance?

At last, all the diversion tunnels were excavated by drilling and blasting method. These optimizations, which increase the direct investment of the project, play a very important role in ensuring the safety and progress of the project, making it possible to generate electricity a year in advance.

How are diversion tunnels constructed?

The diversion tunnels #2 and #4 constructed by drilling and blasting method use the bench method for excavation, trackless transportation for dregs, wet shotcrete for support, rig 353E for drilling anchor holes, and hydraulic steel trolley for lining construction.

Why are diversion tunnels so difficult?

The complex hydrogeological conditions, i.e. the high water pressure, stable water supply, and high in-situ stress over 70 MPa, made the tunnel construction and structure design difficult. The diversion tunnels at Jinping II hydropower station are the largest and the most complicated underground projects so far in the world.

How to excavate diversion tunnels?

At the first stage of construction, the drilling and blasting method was adopted to excavate the diversion tunnels. Then, TBM was used in combination with drilling and blasting method. At last, all the diversion tunnels were excavated by drilling and blasting method.

What are the diversion tunnels at Jinping II Hydropower Station?

The diversion tunnels at Jinping II hydropower station are the largest and the most complicated underground projects so far in the world. The design scheme has been modified and optimized several times, and the construction method and layout have been revised during the tunnel excavation.

Related Articles

-

Photovoltaic power station generator set form

Photovoltaic power station generator set form

-

Malta Yuezhou Photovoltaic Power Station Generator Set

Malta Yuezhou Photovoltaic Power Station Generator Set

-

Southern Europe Mobile Power Station Generator Set

Southern Europe Mobile Power Station Generator Set

-

Main protection of photovoltaic power station generator

Main protection of photovoltaic power station generator

-

35kw photovoltaic power station generator

35kw photovoltaic power station generator

-

Photovoltaic power station private generator

Photovoltaic power station private generator

-

Minsk photovoltaic power station generator

Minsk photovoltaic power station generator

-

Zimbabwe Photovoltaic Power Station Generator

Zimbabwe Photovoltaic Power Station Generator

-

Photovoltaic power station 400kw generator

Photovoltaic power station 400kw generator

-

Beiyacheng Photovoltaic Power Station Generator

Beiyacheng Photovoltaic Power Station Generator

Commercial & Industrial Solar Storage Market Growth

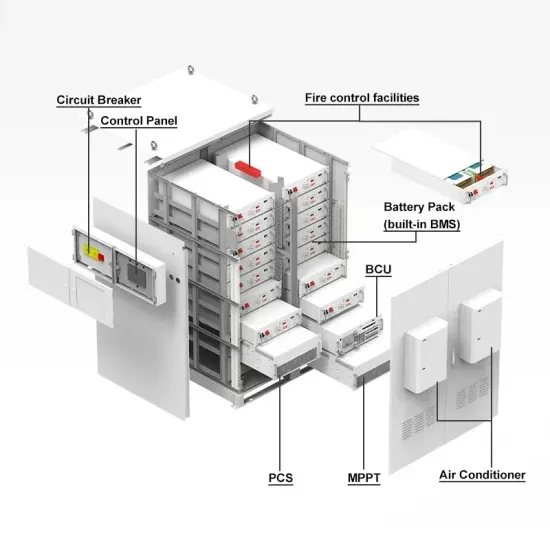

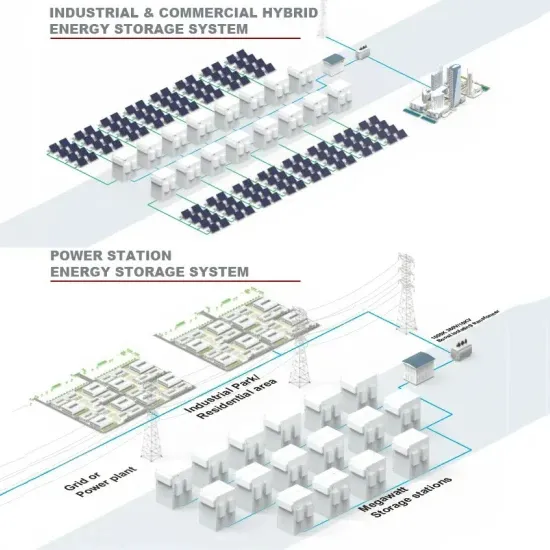

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

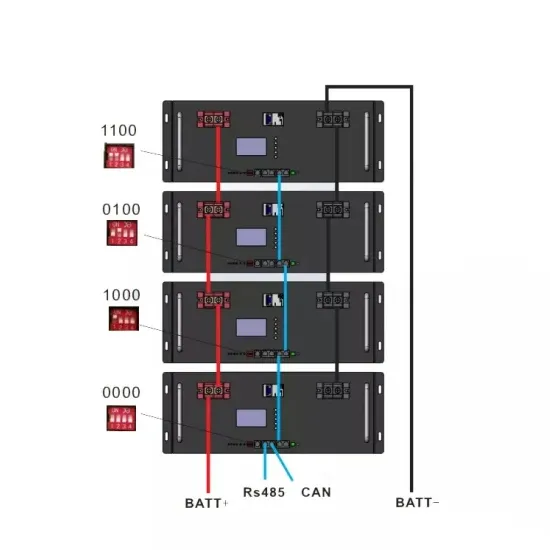

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.