LFP battery BMS 60V 40A

Sep 7, 2021 · The main LFP battery BMS 60V 40A 20S (lithium iron phosphate Battery Management System). An LFP battery (LIFEPO4 32650) management

Get Started

What Are the Typical Specifications of a 60V LiFePO4 Battery?

Sep 6, 2024 · Typical specifications for a 60V LiFePO4 battery include a nominal voltage of 60V, operating voltage range of approximately 44.8V to 67.2V, capacities ranging from 30Ah to over

Get Started

Comparing 60V Batteries to 48V and 72V Options – Wistek

Mar 12, 2025 · Battery Life and Efficiency – A higher voltage battery can reduce current draw, potentially extending battery lifespan. Choosing between a 48V, 60V, and 72V battery

Get Started

Addressing BMS Battery Pack Current and

Apr 5, 2022 · Generally, a BMS measures bidirectional battery pack current both in charging mode and discharging mode. A method called Coulomb counting

Get Started

Decoding BMS: Your Guide to Choosing the

Monitoring Battery Status: BMS measures and calculates vital parameters like battery voltage, current, temperature, power, SOC, SOH, SOP, and SOE.

Get Started

Battery Management System (BMS): Diagrams & IC Selection

Aug 19, 2025 · What is a Battery Management System (BMS)? A Battery Management System (BMS) is the electronics that monitor cell and pack voltage, current, and temperature; estimate

Get Started

Battery Management Systems (BMS): A

Mar 6, 2025 · A Battery Management System (BMS) is essential for ensuring the safe and efficient operation of battery-powered systems. From real-time

Get Started

The Comprehensive Guide to Low Voltage BMS

Sep 27, 2023 · Low voltage BMS is suitable for battery systems with a lower voltage and is usually used for battery service with a voltage of less than 60V.

Get Started

DALY Li-ion NMC 16S 60V 40A Waterproof

Daly 16S 60V 40A BMS is a Lithium Battery Protection Board (PCM BMS) for balance charging. It uses an A-level protective integrated circuit IC. Its high

Get Started

DALY 16S Li-ion 50A Common Port BMS

DALY 16S Li-ion 50A it can collect, process and store the information data of battery in real time and ensure safety, availability and stability of battery.

Get Started

How To Choose A BMS For Lithium Batteries

Sep 27, 2023 · Specifically, low-voltage BMS is designed to serve batteries with voltages of less than 60V and is typically found in lightweight electric vehicles,

Get Started

A Complete Guide to the 60V 100Ah Lithium

Jul 23, 2024 · Choosing a 60V 100Ah lithium battery offers significant advantages for various applications, particularly in electric vehicles and renewable energy

Get Started

How to Wire a Lithium Battery BMS?

Dec 8, 2023 · What Is a Battery Management System (BMS)? A Battery Management System (BMS) is an electronic system that manages and protects lithium batteries by monitoring their

Get Started

Battery Pack Calculator | Good Calculators

Battery Pack Calculator Here''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and

Get Started

Solved: BMS MOSFET

Aug 14, 2024 · Hi Sir What are the main pruducts of 100V MOSFETs for 40V~60V BMS? What are the main parameters that need to focus on ? How to select a suitable MOSFET for a

Get Started

LFP battery BMS 60V 30A

Sep 7, 2021 · Discover the LFP Battery BMS 60V 30A, designed for dependable operation of 60V lithium ferrophosphate (LiFePO4) battery systems. This BMS

Get Started

AshvaVolt 16S 60V 40Amps DALY Li-Ion NMC

Specifications:- Overcurrent, Overcharge, Overdischarge, Short circuit, Temperature protection. DALY BMS maximizes optimizes the lithium battery

Get Started

Understanding the Best Way to Use a 60V

May 16, 2025 · In today''s world, 60V lithium batteries are widely used in various applications, including electric vehicles, power tools, and renewable energy

Get Started

What Size Battery Management System Do I

Nov 2, 2022 · The question of what size battery management system (BMS) you need is a common one, and the answer depends on a few factors. The first is

Get Started

what-you-need-to-know-about-battery-manage

Jan 4, 2020 · When choosing the BMS current, you should consider the matching of the motor power and the controller current. Generally, 250W would choose

Get Started

What Is the Role of a Battery Management System (BMS) in

Nov 6, 2024 · A Battery Management System (BMS) is essential for the safe and efficient operation of lithium-ion battery packs, particularly in applications such as electric vehicles and

Get Started

DALY 16S Li-ion 20A Common Port BMS

DALY 16S Li-ion 20A it can collect, process and store the information data of battery in real time and ensure safety, availability and stability of battery.

Get Started

What Is A 60V Lithium Battery Voltage Chart?

Jul 11, 2025 · A 60V lithium battery voltage chart outlines state-of-charge (SoC) against voltage levels for lithium-ion (Li-ion) or lithium iron phosphate (LiFePO4) systems. At full charge, a 60V

Get Started

The Voltage Conundrum: Is a Surron Better with

Feb 28, 2024 · 60v or 72v battery? Most riders choose the 72 volt option, but is it actually necessary? Read this article if you would like to find out which battery

Get Started

EBMX SURRON BATTERY OPTIONS

May 17, 2023 · • The stock SurRon/Segway battery is a 60Volt 32Ah battery with a limited discharge current. As such, without modifications, the stock battery is unable to be used for

Get Started

What Is The 60V Battery Voltage Chart?

Jul 11, 2025 · A 60V battery voltage chart details the voltage ranges for charge/discharge states, typically spanning 52.5V (empty) to 72V (fully charged), varying by chemistry. Lead-acid

Get Started

Battery Management System

Jul 17, 2024 · A Battery Management System (BMS) is crucial for managing lithium-ion and other types of battery packs, ensuring optimal performance,

Get Started

Battery Management System (BMS): The Definitive Guide

It calculates how much current can safely enter (charge) and flow out (discharge). The BMS can limit the current that prevents the power source (usually a battery charger) and load (such as

Get Started

How Do Voltage-Based and Current-Based Battery

May 25, 2024 · Voltage-based BMS focuses on monitoring the voltage levels of individual cells, while current-based BMS emphasizes tracking the flow of current to manage charging and

Get Started

6 FAQs about [What is the current of a 60v battery bms]

How do I choose a battery management system (BMS)?

Voltage Rating: Confirm that the BMS can handle the total voltage of your battery pack. For example, if you have a 4-cell series lithium-ion pack (3.7V per cell), you need a BMS rated for at least 14.8V. Current Rating: The BMS should support both continuous and peak current ratings that match or exceed your application’s requirements.

How does a BMS measure a battery pack?

Generally, a BMS measures bidirectional battery pack current both in charging mode and discharging mode. A method called Coulomb counting uses these measured currents to calculate the SoC and SoH of the battery pack. The magnitude of currents during charging and discharging modes could be drastically different by one or two orders of magnitude.

How to choose a BMS for lithium batteries?

If you are looking to build safe-high performance battery packs, then you are going to need to know how to choose a BMS for lithium batteries. The primary job of a BMS is to prevent overloading the battery cells. So, for this to be effective, the maximum rating on the BMS should be greater than the maximum amperage rating of the battery.

How to choose BMS current?

When choosing the BMS current, you should consider the matching of the motor power and the controller current. Generally, 250W would choose 15A or 20A, 350W would choose 20A, 500W would choose 30A, 800W would chooses 40A, 1000W would choose 45A or bigger. The Continuous current of BMS should be bigger than the max current of the Controller.

How does a BMS measure bidirectional battery pack current?

Therefore, in discharging mode, current flows in the opposite direction from charging mode, out of the HV+ terminal. Generally, a BMS measures bidirectional battery pack current both in charging mode and discharging mode. A method called Coulomb counting uses these measured currents to calculate the SoC and SoH of the battery pack.

What is BMS low voltage?

Today, we will mainly explore BMS low voltage. Specifically, low-voltage BMS is designed to serve batteries with voltages of less than 60V and is typically found in lightweight electric vehicles, such as e-bikes, electric motorcycles, e-scooters, freight bikes, or small-scale renewable energy systems.

Related Articles

-

What does BMS battery system mean

What does BMS battery system mean

-

BMS current limiting charging of lithium battery in communication base station

BMS current limiting charging of lithium battery in communication base station

-

What battery is durable for 60v series inverter

What battery is durable for 60v series inverter

-

What does BMS battery pack mean

What does BMS battery pack mean

-

What is the use of lithium battery BMS

What is the use of lithium battery BMS

-

What is the discharge current of the 12v energy storage cabinet battery

What is the discharge current of the 12v energy storage cabinet battery

-

What does the new energy storage cabinet and battery cabinet include

What does the new energy storage cabinet and battery cabinet include

-

What is the voltage of photovoltaic energy storage lithium battery

What is the voltage of photovoltaic energy storage lithium battery

-

What is the DC current of a 24v5000w inverter

What is the DC current of a 24v5000w inverter

-

What do you need to build a lithium battery pack

What do you need to build a lithium battery pack

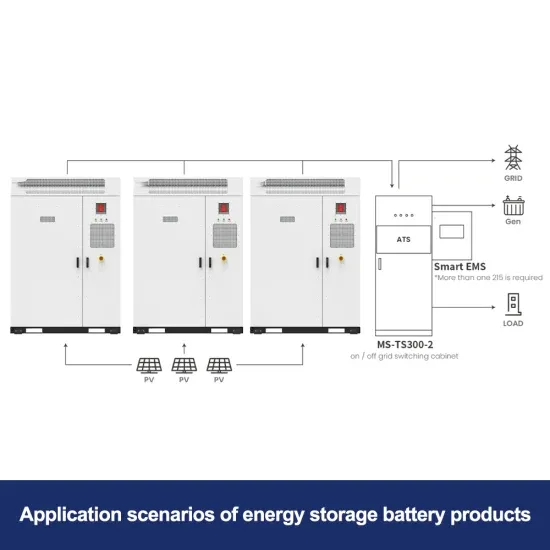

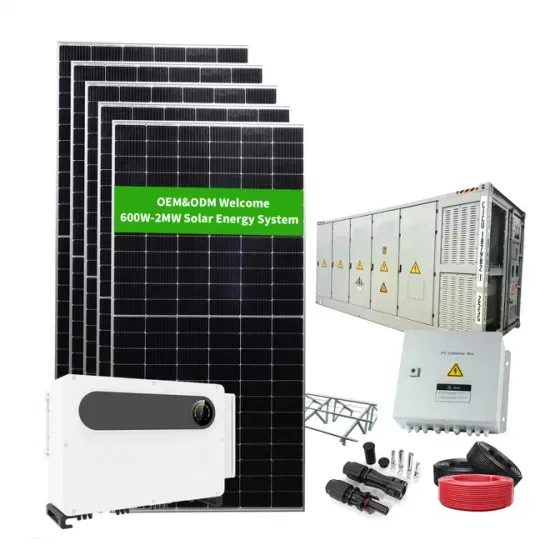

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.