Solar tracking systems: Technologies and trackers drive types

Aug 1, 2018 · The solar tracker drive systems encompassed five categories based on the tracking technologies, namely, active tracking, passive tracking, semi-passive tracking, manual

Get Started

Solar Tracking Gearmotor

Aug 17, 2025 · Solar tracking engine is a type of engine system used in solar energy systems. These motors are used to control and adjust the solar panels''

Get Started

Brushless Servo Motor for Solar Tracker

MoveMatic BLDC Motors, DC Geared motor is relatively efficient, easily controllable for solar tracking applications in India. Brushless Servo Motor

Get Started

Single Axis Solar Tracking System using Microcontroller

Apr 20, 2018 · In hardware development, two light dependent resistor (LDR) has been used for capturing maximum light source. Servo motor has been used to move the solar panel at

Get Started

Solar Tracking System Using Stepper Motor

Jun 18, 2014 · Maximizing the output power from solar panel and integrating solar tracking system are the two ways where electronic design methodology can bring success. Maximum power

Get Started

Servo Motor Applications (Robotics, Solar

Feb 24, 2012 · A servo motor operates on the principle of a servomechanism and is used in many applications that require precise position control. Using a DC

Get Started

Performance Analysis of Dual-Axis Solar Tracking System

Feb 28, 2019 · Light Dependent Resistor acts as a sensor is used to trace the coordinate of the sunlight by detecting brightness level of the sunlight and DC motor is used to control the

Get Started

What is a solar tracker and how does it work?

Jan 16, 2020 · One proven way to increase a system''s output is by using a solar tracker, which makes solar panels follow the sun''s path throughout the day.

Get Started

Solar Tracking System: Its Working, Types, Pros,

Jul 29, 2025 · A solar tracking system is a mechanical device that positions solar panels in such a way that they remain perpendicular to the sun throughout the

Get Started

What Is A Solar Tracker And Is It Worth The

Solar trackers are devices that allow your solar panel array to follow the sun''s path in the sky to produce more energy for you to use. Solar tracking systems

Get Started

Solar Tracking System Using Stepper Motor

Jun 18, 2014 · Solar panels directly convert solar radiation into electrical energy. Solar panel is mainly made from semiconductor materials. Si used as the major component of solar panels,

Get Started

Designing with solar tracking motors

Jun 7, 2012 · The electric motors that move these tracking systems are typically small fractional horsepower models (less than 745 W) whose own energy

Get Started

One-Axis Tracker

Because solar tracking implies moving parts and control systems that tend to be expensive, single-axis tracking systems seem to be the best solution for small PV power plants. A single

Get Started

DESIGN AND CONSTRUCTION OF SOLAR TRACKING

Aug 19, 2025 · The solar tracking system uses two motors as the drive source, stepper motor (M1) and DC motor (M2) conducting (Figure 2). The two motors are decoupled, i.e., the

Get Started

Which kind of motor is used in solar tracking system?

Aug 29, 2024 · The primary types of motors utilized in solar tracking systems include DC motors, stepper motors, and servo motors. Each type serves distinct roles depending on application

Get Started

Full article: Solar tracking system – a review

Jan 4, 2017 · In this context solar tracking system is the best alternative to increase the efficiency of the photovoltaic panel. Solar trackers move the

Get Started

What are the motors for solar power generation? | NenPower

Aug 29, 2024 · The landscape of solar power systems is characterized by a variety of motors that cater to specific operational demands. DC motors, stepper motors, and servo motors

Get Started

A simple and low‐cost active dual‐axis solar tracker

Sep 23, 2018 · This paper presents the design and practical implementation of a simple active dual-axis solar tracker (DAST) to track the sun''s movement by

Get Started

Solar Tracking System

A solar tracking system is defined as a mechanism designed to follow the sun''s path, ensuring that photovoltaic panels remain perpendicular to solar radiation, thereby maximizing energy

Get Started

PLC BASED SOLAR TRACKING SYSTEM

Apr 7, 2021 · The target of this project was to establish a solar tracking system with programmable logic controller as its controlling unit. More specifically this project concerned

Get Started

How do various solar trackers work and are they

Dec 17, 2024 · Wider adoption of solar trackers can play an instrumental role in attaining that goal, as solar trackers have much higher energy output than

Get Started

Types of Solar Trackers and their Advantages

Jul 11, 2023 · For example, a solar panel system might use dual-axis tracking to ensure maximum efficiency, much like how an LED street light adjusts its

Get Started

What is a solar tracker? Advantages and

Oct 8, 2019 · A solar tracker is a device that orients the solar panels to the Sun. Advantages and disadvantages of these solar systems.

Get Started

Solar Tracking Motor

Jul 7, 2025 · Both the motors and the gearheads attached to them must be optimized for the low speeds and high torque that characterize solar tracking.

Get Started

An introduction to Solar Motors & Drives

Feb 23, 2012 · Motors on solar positioning equipment orient panels to follow the sun daily and seasonally. There are four basic types of electric motors used in

Get Started

Solar Tracker System by using Arduino and LDR

Feb 17, 2025 · The Single-Axis Solar Tracker System is an efficient way to maximize the efficiency of solar panels by dynamically adjusting their

Get Started

Solar Panel Tracking Systems

Jun 20, 2025 · Among the list of various tracking systems installations, active solar tracking systems are the prime ones. These tracking systems have an in

Get Started

The design of DC motor driver for solar tracking

Sep 1, 2012 · Solar trackers rely on a direct-current (DC) motor driver circuit to control the movement of the solar panel. However, conventional DC motor

Get Started

What motor do solar panels use? | NenPower

Oct 18, 2024 · Stepper motors are commonly used in tracking systems, as they provide precise control over movement in small increments. This granularity

Get Started

Application of Servo Motor Drive Technologies for Solar Panel Tracking

Jul 24, 2025 · Servo motors play an important role in precision motion control applications across various industries. Advanced drive technologies enable high-performance control in key

Get Started

6 FAQs about [Motors used in solar tracking systems]

What is a solar tracking motor?

Another solar tracking motor widely used in the solar tracking market is the motor which has 56mm 24V DC motor with 56mm planetary gearbox. It could output around 50-100W with relatively high torque. The mainstream solar tracking systems on the market are using this type of geared motor.

Why do industrial solar tracking motors need a gearbox?

Industrial solar tracking system requires a huge torque to rotate large-area solar panels, which means that solar tracking motors need the cooperation of a gearbox to achieve high-torque and low-speed control.

Can linear motors be used to create a solar tracking system?

This thesis project aimed to explore the programming of linear motors in an attempt to create a solar tracking panel system, and to examine the value of sun tracking as opposed to fixed panels. The program described in this paper utilizes Siemens’ adaptation of a sun tracking algorithm to create single and dual axis tracking.

Are electric motors suitable for solar photovoltaic tracking applications?

When it comes to specifying electric motors for solar photovoltaic tracking applications, environmental protection is a prime consideration due to their exposure to the elements.

Which planetary gear motor is used in solar tracking system?

Here are two main planetary gear motor which applied on the solar tracking system market. One of most popular Solar tracking motor PG-80 ( DONCENMOTOR ) This motor is 80mm 48V BLDC motor with 120mm planetary gearbox which could output 290N.m with 2 rpm at working point. The large torque means it could afford more solar panels with a single motor.

How a solar tracker motor can improve solar absorption?

Through changing the position of the solar panel to achieve the solar panel could face to the sun light directly in days. This machine could improve the solar absorption. 3.1: Which kind of motor are used in solar tracking system (Solar tracker motor)?

Related Articles

-

Solar Tracking Systems in Southern Europe

Solar Tracking Systems in Southern Europe

-

Chisinau new solar energy systems for sale

Chisinau new solar energy systems for sale

-

How many solar panels are used for a 5kw inverter

How many solar panels are used for a 5kw inverter

-

How many watts of solar energy can be used at home

How many watts of solar energy can be used at home

-

Private production of solar power generation systems

Private production of solar power generation systems

-

Can solar energy be used to pump water

Can solar energy be used to pump water

-

Is Sucre used as a solar system

Is Sucre used as a solar system

-

Hybrid energy storage systems are widely used in

Hybrid energy storage systems are widely used in

-

Which type of energy storage is used for solar energy

Which type of energy storage is used for solar energy

-

Are home solar systems cost-effective

Are home solar systems cost-effective

Commercial & Industrial Solar Storage Market Growth

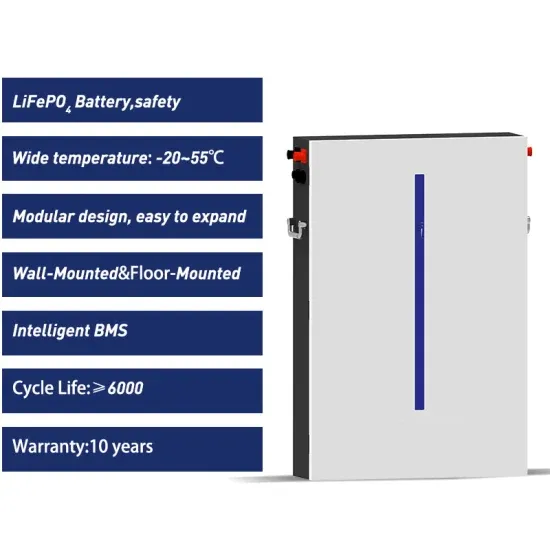

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.