How To Balance A Lithium Batteries: Top and

Oct 3, 2022 · A balanced battery pack is critical to getting the most capacity out of your pack, read along to learn how to top and bottom balance a lithium battery

Get Started

BMS and lithium battery balancing: What is it?

May 25, 2021 · The key function of a lithium battery BMS is cell balancing. What is a conventional BMS and how is the Flash Balancing System different?

Get Started

NTC Thermistor Temperature Sensors Provide Li

NTC thermistor temperature sensors are a key component in Li-Ion battery charging and safety. They provide critical temperature data required to keep

Get Started

Detection and isolation of faults in a lithium-ion battery pack

Jun 15, 2024 · This paper presents a method of detecting a single occurrence of various common faults in a Lithium-ion battery pack and isolating the fault to the faulty PCM, its connecting

Get Started

Guide: Battery internal resistance – what, why

Feb 1, 2020 · If the internal resistance increases on one of the battery cells this means the battery will supply less current and will probably heat up more than

Get Started

INSTRUCTION MANUAL: BATTERY PACK DESIGN, BUILD

Apr 29, 2021 · Match the cells to combine in parallel/series with the rePackr - 18650 pack builder tool. This is done according to capacity and internal resistance to get the most similar values in

Get Started

Pack Internal Resistance

Pack Internal Resistance A key parameter to calculate and then measure is the battery pack internal resistance. This is the DC internal resistance (DCIR) and

Get Started

Internal resistance matching for parallel-connected lithium

Apr 15, 2014 · We demonstrate the importance of resistance matching in battery packs. At 4.5C charge and discharge, 20% resistance mismatch reduces lifetime by 40%. We quantitatively

Get Started

Capacity and Internal Resistance of lithium-ion batteries: Full

Feb 1, 2023 · The use of minimal information from battery cycling data for various battery life prognostics is in high demand with many current solutions requiring full in-cycle data recording

Get Started

Why is it Important to Measure Battery''s Internal

Quality Inspection during Battery Production The first reason for measuring internal resistance is to ensure quality control throughout production. It is

Get Started

Lithium ion battery internal resistance

5 days ago · Due to the small internal resistance of the rechargeable battery, the DC internal resistance is measured due to the electrode capacity polarization, resulting in the polarization

Get Started

Key Factors Affecting Lithium-Ion Battery Resistance

Apr 29, 2025 · Internal resistance in lithium-ion battery packs refers to the opposition within the battery that restricts the flow of electric current. This resistance directly impacts battery

Get Started

Lithium battery internal resistance capacity comparison

is the typical internal resistance of a lithium-ion battery? The typical internal resistance of a li hium-ion battery varies depending on its capacity and design. G nerally, it ranges from a few

Get Started

Optimizing Internal Resistance of Lithium-ion

Oct 24, 2023 · In the performance evaluation of lithium-ion cells/batteries, internal resistance is an essential indicator. Bonnen''s engineering team will provide a

Get Started

Lithium Battery Pack Protection and Control

Market trends and drivers Safety and ageing concerns in Lithium battery applications highlight the critical need for advanced protection and control solutions in the market. Adoption of electric

Get Started

How to calculate the internal resistance of a

In this technical article, we delve into the topic of using the discharge characteristic of a battery cell to determine its internal resistance. We also

Get Started

Battery Protection ICs for 1-cell Pack

Jul 30, 2025 · ABLIC''s battery protection ICs for multi-cell pack: Our vast product lineup provides strong support for developing safety-critical battery packs with

Get Started

Lithium Battery Internal Resistance: Effects on

Feb 4, 2025 · Learn how lithium battery internal resistance affects performance, capacity, and lifespan, and discover ways to reduce resistance and improve

Get Started

How to Spot Weld Lithium Batteries

This forms a strong, low-resistance joint, which is vital for battery pack stability. For lithium batteries, precision is crucial to prevent damage to internal

Get Started

A Guide to Designing A BMS Circuit Diagram for

Jan 17, 2024 · Lithium-ion batteries have become extremely popular due to their wide application in portable electronics. However, unlike lead-acid or nickel

Get Started

BU-902: How to Measure Internal Resistance

Nov 4, 2021 · The resistance of modern lead acid and lithium-ion batteries stays flat through most of the service life. Better electrolyte additives have reduced

Get Started

A complete analysis of lithium battery internal

Apr 30, 2025 · 1️⃣ Internal resistance and polarization internal resistance: the "invisible resistance" of the battery The internal resistance of a lithium battery

Get Started

Pre-Charge Resistor

Dec 12, 2022 · The time taken to pre-charge the capacitors in the HV system will depend on the resistance in the total circuit, the voltage of the battery pack

Get Started

How internal resistance affects battery

Jan 23, 2025 · Internal resistance in batteries reduces efficiency and lifespan by causing voltage drops and heat generation. It is influenced by factors like

Get Started

How to Measure Internal Resistance in Lithium

Nov 28, 2024 · Understand internal resistance in lithium batteries and its effects on performance. Find out how to measure it and enhance your battery''s

Get Started

Battery Internal Resistance: Lithium & LiFePO4

Jan 29, 2024 · Lithium-ion battery internal resistance is critical in determining battery performance, efficiency, and lifespan. Understanding what it is, how to

Get Started

Fault diagnosis and quantitative analysis of micro-short

Aug 15, 2018 · Micro-short circuit (MSC) of a lithium-ion battery cell is a potential safety hazard for battery packs. How to identify the cell with MSC in the laten

Get Started

Internal Resistance: DCIR and ACIR

Oct 29, 2022 · Internal Resistance: DCIR and ACIR:- Let''s take a tiny step and understand how IR is measured in the first place. How are resistances

Get Started

Factors Affecting The Internal Resistance of

Mar 30, 2023 · With the use of lithium-ion batteries, the battery performance continuously deteriorates, mainly manifested as capacity attenuation, internal

Get Started

How to Assemble a Lithium-Ion Battery Pack

Oct 7, 2024 · Learn how to safely assemble a battery pack with a BMS module. Our step-by-step guide covers materials needed, safety precautions, detailed

Get Started

How does Internal Resistance affect

Sep 17, 2021 · The battery tested has a capacity of 94%, the internal resistance is 320 mOhm. Internal resistance as a function of state-of-charge The internal

Get Started

6 FAQs about [Small resistor in lithium battery pack]

What is the internal resistance of a lithium battery?

1️⃣ Internal resistance and polarization internal resistance: the "invisible resistance" of the battery The internal resistance of a lithium battery is the resistance encountered when the current flows through the inside of the battery, which directly affects the power performance and heating efficiency of the battery.

How to reduce internal resistance of lithium ion cells/batteries?

Temperature plays a substantial role in influencing internal resistance. Generally, higher temperatures lead to lower internal resistance. To enhance the performance of lithium-ion cells/batteries, various measures can be employed to reduce internal resistance. Here are some common methods: 1. Optimization of Battery Materials

How do you measure internal resistance of a lithium battery?

The internal resistance of a lithium battery can be measured using specialized equipment like battery analyzers or dedicated internal resistance meters. These devices apply a small known current to the battery and measure the voltage drop across it to calculate internal resistance. How do you reduce internal battery resistance?

Why is internal resistance a limiting factor in lithium ion batteries?

Internal resistance is one of the limiting factors for the output power of lithium-ion batteries. When the internal resistance of the battery is high, the current passing through the battery will result in a significant voltage drop, leading to a reduction in the battery’s output power. b. Internal resistance leads to self-discharge in batteries.

What is the internal resistance of a battery?

Too small internal resistance: Although it reduces energy consumption, it requires optimization of materials and processes, and the cost is high. Industry standard: The internal resistance of power batteries usually needs to be <15mΩ, and that of consumer batteries is 30-80mΩ.

What is the internal resistance of a lithium ion 18650 battery?

Typically, it ranges from a few milliohms (mΩ) to tens of milliohms. What is the internal resistance of a lithium-ion 18650 battery? The internal resistance of a lithium-ion 18650 battery may vary based on the specific model, age, and condition. Generally, it can range from around 20 to 80 milliohms (mΩ) for these types of batteries.

Related Articles

-

Lithium battery pack small cells

Lithium battery pack small cells

-

Small lithium battery pack customization

Small lithium battery pack customization

-

Moroni battery replacement lithium battery pack

Moroni battery replacement lithium battery pack

-

8How many mAh is the lithium battery pack

8How many mAh is the lithium battery pack

-

How many volts does the lithium battery pack discharge to

How many volts does the lithium battery pack discharge to

-

Pack lithium battery display cabinet

Pack lithium battery display cabinet

-

Xia 12v lithium battery pack

Xia 12v lithium battery pack

-

Venezuela lithium battery pack charge and discharge times

Venezuela lithium battery pack charge and discharge times

-

24v lithium battery 100ah battery pack

24v lithium battery 100ah battery pack

-

Lithium battery pack can be partially replaced

Lithium battery pack can be partially replaced

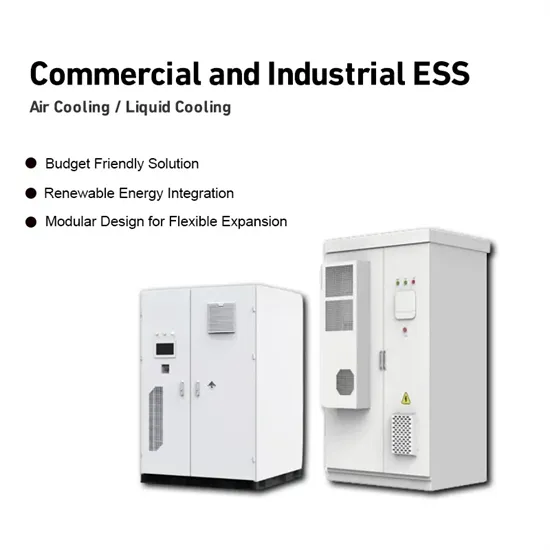

Commercial & Industrial Solar Storage Market Growth

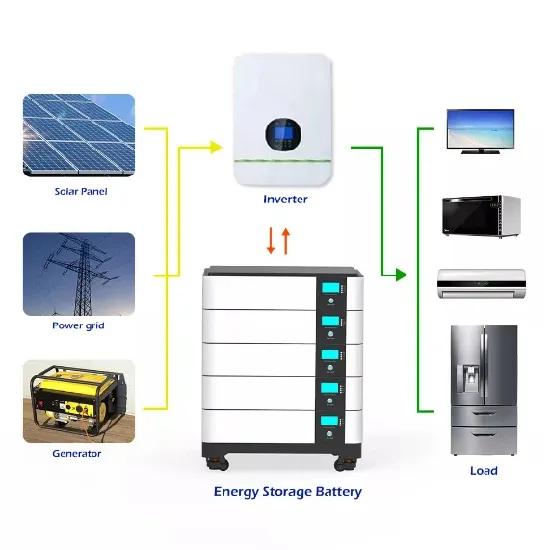

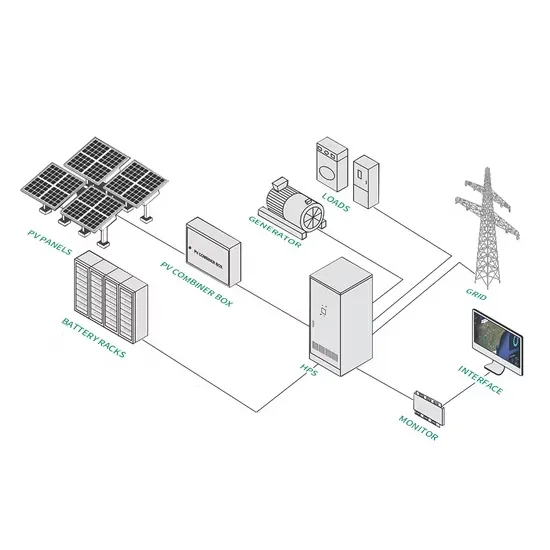

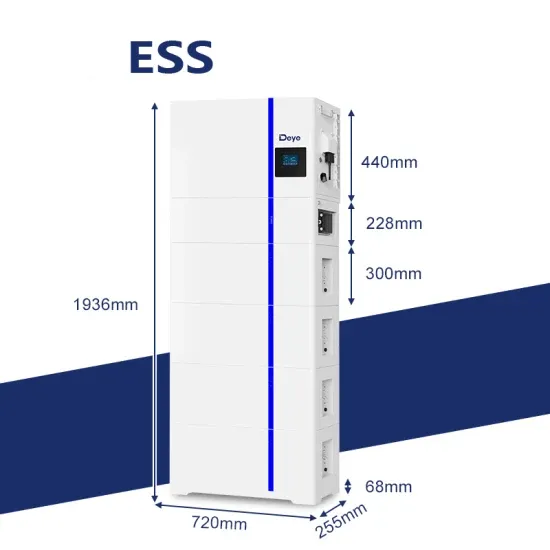

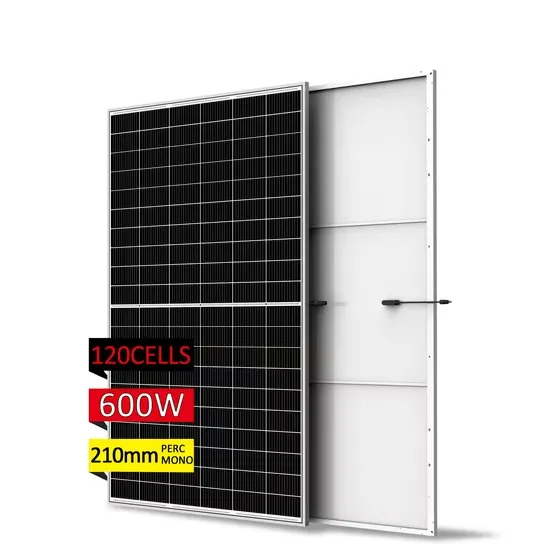

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.