A Review of Flywheel Energy Storage System Technologies

Flywheels have attributes of a high cycle life, long operational life, high round-trip efficiency, high power density, low environmental impact, and can store megajoule (MJ) levels of energy with

Get Started

Jet impingement cooling in rotating flywheel energy storage

Jul 1, 2025 · As an innovative energy storage technology, flywheel energy storage systems (FESS) have garnered substantial research interest in recent years, particularly regarding their

Get Started

Design and Research of a New Type of Flywheel Energy Storage

Feb 18, 2025 · Li Xiaojun [19] proposed a novel combined 5-DOF energy storage flywheel (C5AMB) for shaft-free, hub-free, high-strength steel energy storage flywheels (SHFES). The

Get Started

A review of flywheel energy storage rotor materials and structures

Oct 19, 2023 · The flywheel is the main energy storage component in the flywheel energy storage system, and it can only achieve high energy storage density when rotating at high speeds.

Get Started

Design, modeling, and validation of a 0.5 kWh flywheel energy storage

Nov 1, 2024 · The flywheel energy storage system (FESS) has excellent power capacity and high conversion efficiency. It could be used as a mechanical battery in the

Get Started

Flywheel Energy Storage System in the Grid with the

Nov 14, 2021 · This article presents the structure of the Flywheel Energy Storage System (FESS) and proposes a plan to use them in the grid system as an energy "regulating" element. The

Get Started

A review of stress analysis on materials and structures for flywheel

Aug 19, 2025 · As the core component for energy storage, the rotor''s stress distribution and evolution under high-speed rotation directly affect the system''s safety and reliability. This

Get Started

Dynamics Study of Hybrid Support Flywheel

Dec 23, 2024 · The flywheel energy storage system (FESS) of a mechanical bearing is utilized in electric vehicles, railways, power grid frequency

Get Started

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Get Started

A Review of Flywheel Energy Storage Systems for Grid

Oct 23, 2018 · Increasing levels of renewable energy generation are creating a need for highly flexible power grid resources. Recently, FERC issued order number 841 in an effort to create

Get Started

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power

Get Started

Design, Fabrication, and Test of a 5 kWh Flywheel Energy

Oct 28, 2021 · Introduction A flywheel energy storage system typically works by combining a high-strength, high-momentum rotor with a shaft-mounted motor/generator. This assembly is

Get Started

Energy storage flywheel electromagnetic field

Flywheel energy storage systems: A critical review on technologies, applications, and future prospects This structure is a combination of the rotor''''s energy storage parts and

Get Started

A review of control strategies for flywheel energy storage

Nov 1, 2022 · The flywheel energy storage system (FESS) offers a fast dynamic response, high power and energy densities, high efficiency, good reliability, long lifetime and low maintenance

Get Started

Flywheel Energy Storage Systems and Their

Apr 1, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel

Get Started

Review of Flywheel Energy Storage Systems structures and applications

Mar 1, 2017 · Flywheel Energy Storage System (FESS) is an electromechanical energy storage system which can exchange electrical power with the electric network. It consists of an

Get Started

Coordinated Control of Flywheel and Battery Energy Storage

Apr 10, 2025 · Due to the inherent slow response time of diesel generators within an islanded microgrid (MG), their frequency and voltage control systems often struggle to effectively

Get Started

FINAL VERSION.pdf

Aug 11, 2021 · Active magnetic bearing Combination Active magnetic bearing Combined radial-axial magnetic bearing Combination 5 degree-of-freedom active magnetic bearing Flywheel

Get Started

Flywheel Energy Storage Systems: A Critical Review on

Nov 15, 2021 · Flywheel energy storage systems: A critical review on technologies, applications, and future prospects Subhashree Choudhury Department of EEE, Siksha ''O'' Anusandhan

Get Started

CN201298770Y

The utility model provides a flywheel energy storing device with combined support structure which includes a case and a motor, the flywheel and a support structure set in the case hollow cavity.

Get Started

A Review of Flywheel Energy Storage System Technologies

Jul 6, 2024 · Using energy storage technology can improve the stability and quality of the power grid. One such technology is fly- wheel energy storage systems (FESSs). Compared with

Get Started

Design and control of a novel flywheel energy storage

Apr 1, 2013 · It is the intention of this paper to propose a compact flywheel energy storage system assisted by hybrid mechanical-magnetic bearings. Concepts of act

Get Started

Design of Flywheel Energy Storage System – A Review

Aug 24, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extensively

Get Started

Review of Flywheel Energy Storage Systems structures and applications

Mar 1, 2017 · Abstract Flywheel Energy Storage System (FESS) is an electromechanical energy storage system which can exchange electrical power with the electric network. It consists of an

Get Started

1 Introduction

Aug 6, 2020 · 1 Introduction Presently many types of spacecraft use a Spacecraft Attitude Control System (ACS) with momentum wheels tbr steering and electrochemical batteries to provide

Get Started

A review of flywheel energy storage systems: state of the art

Mar 16, 2024 · The existing energy storage systems use various technologies, including hydroelectricity, batteries, supercapacitors, thermal storage, energy storage flywheels, [2] and

Get Started

A comprehensive review of Flywheel Energy Storage System

Jan 1, 2017 · Energy storage systems (ESSs) play a very important role in recent years. Flywheel is one of the oldest storage energy devices and it has several benefits. Flywheel Energy

Get Started

A cross-entropy-based synergy method for capacity

Feb 1, 2025 · Energy storage systems, coupled with power sources, are applied as an important means of frequency regulation support for large-scale grid connection of new energy. Flywheel

Get Started

Optimising flywheel energy storage systems for enhanced

Jun 1, 2025 · Concerns about global warming and the need to reduce carbon emissions have prompted the creation of novel energy recovery systems. Continuous braking results in

Get Started

Design of Flywheel Energy Storage System – A Review

Aug 24, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extens

Get Started

A Review of Flywheel Energy Storage System

Mar 16, 2017 · Energy, Exergy and Economic (3E) analysis and multi-objective optimization of a combined cycle power system integrating compressed air

Get Started

Simulation and evaluation of flexible enhancement of

Oct 15, 2023 · The flywheel energy storage system is also suitable for frequency modulation. In power generation enterprises, the primary flexible operation abilities of the units which will be

Get Started

The Flywheel Energy Storage System: A Conceptual

Feb 16, 2024 · Abstract−While energy storage technologies cannot be considered sources of energy; they provide valuable contributions to enhance the stability, power quality and

Get Started

Flywheel energy storage systems: Review and simulation for

Dec 1, 2012 · Flywheel energy storage systems (FESSs) store mechanical energy in a rotating flywheel that convert into electrical energy by means of an electrical machine and vice versa

Get Started

6 FAQs about [Flywheel energy storage combined structure]

Are flywheel energy storage systems environmentally friendly?

Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage and release, high power density, and long-term lifespan. These attributes make FESS suitable for integration into power systems in a wide range of applications.

Can flywheel energy storage system array improve power system performance?

Moreover, flywheel energy storage system array (FESA) is a potential and promising alternative to other forms of ESS in power system applications for improving power system efficiency, stability and security . However, control systems of PV-FESS, WT-FESS and FESA are crucial to guarantee the FESS performance.

What is flywheel energy storage system (fess)?

Flywheel Energy Storage System (FESS) is an electromechanical energy storage system which can exchange electrical power with the electric network. It consists of an electrical machine, back-to-back converter, DC link capacitor and a massive disk.

How does a flywheel energy storage system work?

Based on the aforementioned research, this paper proposes a novel electric suspension flywheel energy storage system equipped with zero flux coils and permanent magnets. The newly developed flywheel energy storage system operates at high speeds with self-stability without requiring active control.

What is a flywheel & how does it work?

Flywheels with the main attributes of high energy efficiency, and high power and energy density, compete with other storage technologies in electrical energy storage applications, as well as in transportation, military services, and space satellites .

What is a flywheel energy storage unit?

A flywheel energy storage unit is a mechanical system designed to store and release energy efficiently. It consists of a high-momentum flywheel, precision bearings, a vacuum or low-pressure enclosure to minimize energy losses due to friction and air resistance, a motor/generator for energy conversion, and a sophisticated control system.

Related Articles

-

New Energy Charging Station Flywheel Energy Storage Station

New Energy Charging Station Flywheel Energy Storage Station

-

How many times can the flywheel energy storage be adjusted in a day

How many times can the flywheel energy storage be adjusted in a day

-

Flywheel energy storage vehicle is UPS

Flywheel energy storage vehicle is UPS

-

Power generation price of flywheel energy storage

Power generation price of flywheel energy storage

-

What is the communication base station flywheel energy storage to optical exchange

What is the communication base station flywheel energy storage to optical exchange

-

Flywheel energy storage unit energy

Flywheel energy storage unit energy

-

Flywheel energy storage for communication base stations

Flywheel energy storage for communication base stations

-

Invest in 5g communication base station flywheel energy storage

Invest in 5g communication base station flywheel energy storage

-

Flywheel Energy Storage Investment Company

Flywheel Energy Storage Investment Company

-

How many hours of flywheel energy storage

How many hours of flywheel energy storage

Commercial & Industrial Solar Storage Market Growth

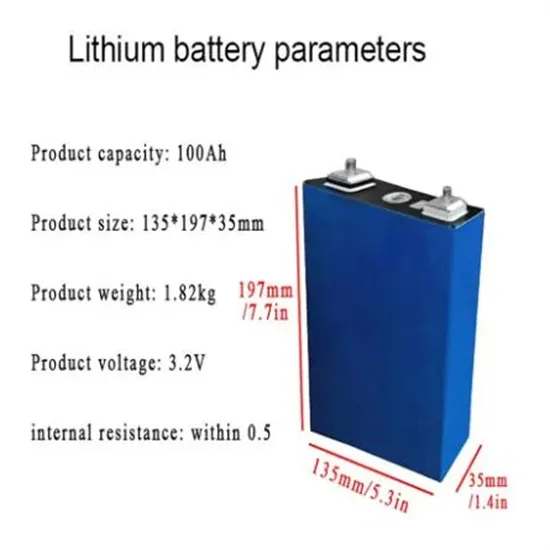

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.