Global Silicon Carbide (SiC) Inverters Market 2025-2035

Mar 5, 2025 · Silicon Carbide (SiC) Inverters Market Size, Share & Trends Analysis Report by Inverter Type (Single-phase Inverters, Three-phase Inverters, and Multilevel Inverters), and

Get Started

800V Silicon Carbide Inverter Market | Size, Share, Price,

Apr 16, 2023 · We surveyed the 800V Silicon Carbide Inverter manufacturers, suppliers, distributors and industry experts on this industry, involving the sales, revenue, demand, price

Get Started

Developing Trends & Challenges for SiC Based Power Inverters

Mar 24, 2023 · The technology has evolved from Insulated Gate Bipolar Transistors (IGBTs) to Silicon Carbide as a response to size and weight considerations. SiC inverters provide

Get Started

Semiconductor technology in solar inverters: future

Mar 10, 2025 · Silicon carbide (SiC) semiconductors, with their wide bandgap characteristics, significantly improve the power density and efficiency of inverters. Compared with traditional

Get Started

Global High Voltage SiC(Silicon Carbide) Inverter

Apr 25, 2025 · Global high voltage sic (silicon carbide) inverter accounted for $XX Billion in 2022 and is anticipated to reach $XX Billion by 2030, registering a

Get Started

Ultra High Purity Silicon Carbide Market Size, Share & 2030

4 days ago · Ultra High Purity Silicon Carbide Market Analysis by Mordor Intelligence The Ultra High Purity Silicon Carbide Market size is estimated at USD 7.78 billion in 2025, and is

Get Started

Hybrid DC/AC inverter by BORG WARNER

Our 800-Volt Silicon Carbide Inverter for Electrified Vehicles uses an innovative, double-side cooled silicon carbide (SiC) based power switch that delivers the

Get Started

Katek unveils silicon carbide inverter for

Jan 31, 2023 · Katek Memmingen GmbH says it is currently manufacturing its 4.6 kW coolcept fleX three-phase inverter with SiC semiconductors from US

Get Started

Global Silicon Carbide Inverter Market Research Report 2025

The Silicon Carbide Inverter market size, estimations, and forecasts are provided in terms of output/shipments (K Units) and revenue ($ millions), considering 2024 as the base year, with

Get Started

The Next Wave of SiC: Manufacturing, Supply

Aug 14, 2025 · The silicon carbide (SiC) industry is growing in many markets. The electric vehicle (EV) market is preparing to move toward SiC inverters, as

Get Started

EV expansion means new prospects for silicon

Oct 17, 2023 · Rising EV adoption spikes demand for silicon carbide (SiC) power electronics components. How can semiconductor players and automotive

Get Started

Silicon Carbide (SiC) Inverters Market 2026: Automation, AI

Jun 10, 2025 · Silicon Carbide (SiC) Inverters Market size was valued at USD 1.2 Billion in 2022 and is projected to reach USD 3.

Get Started

Silicon Carbide Traction Inverter

6 days ago · Silicon Carbide Traction Inverter, Find Details and Price about Traction Inverter from Silicon Carbide Traction Inverter - CRRC Yongji Electric Co., Ltd.

Get Started

Silicon Carbide Inverters

This report aims to provide a comprehensive presentation of the global market for Silicon Carbide Inverters, focusing on the total sales volume, sales revenue, price, key companies market

Get Started

Silicon Carbide Market Size, Growth Report

Oct 30, 2024 · As EV and renewable inverters proliferate, production learning curves are forecast to narrow the price gap versus black SiC, enlarging

Get Started

IGBT-SiC chip cuts inverter costs

Home > The Grid > IGBT-SiC chip cuts inverter costs IGBT-SiC chip cuts inverter costs The hybrid silicon carbide and silicon transistor inverter outperforms

Get Started

Global Silicon Carbide Inverter Market 2025 by

Feb 21, 2025 · Chapter 2, to profile the top manufacturers of Silicon Carbide Inverter, with price, sales quantity, revenue, and global market share of Silicon Carbide Inverter from 2020 to 2025.

Get Started

800V Silicon Carbide Inverter

Jan 13, 2025 · Chapter 2: Detailed analysis of 800V Silicon Carbide Inverter manufacturers competitive landscape, price, sales and revenue market share, latest development plan,

Get Started

Silicon Carbide (SiC) Inverters Market Scope, Trends, Strategy

Jul 20, 2025 · The Silicon Carbide (SiC) Inverters Market Segmentation Analysis offers a comprehensive breakdown of the market by identifying and evaluating key consumer

Get Started

Silicon Carbide Power Inverter Technology is

Sep 13, 2021 · This first-generation CoolSiC automotive MOSFET technology is optimized for use in EV traction inverters, with a focus on minimizing

Get Started

CTI Silicon Carbide Inverter for Electric Vehicles

CTI-4 is the next generation in 3 Phase Silicon Carbide Inverter technology from Helix. Designed for hybrid and electric vehicles in automotive, marine, and off

Get Started

Hybrid Si IGBT, SiC MOSFET Power Modules Add

Jun 23, 2025 · In March 2023, Tesla CEO Elon Musk said that the electric vehicle maker will use 75% less silicon carbide (SiC) without compromising the

Get Started

Silicon Carbide Inverter

Aug 16, 2025 · Developed and produced in-house, this silicon carbide (SiC) inverter delivers highly efficient power usage. Its design is dedicated to

Get Started

Tesla moves to cut SiC use in electric vehicles

Mar 4, 2023 · Tesla is developing a new powertrain for lower cost electric vehicles (EVs) that could use 75% less silicon carbide (SiC) power MOSFETs. The

Get Started

Silicon carbide enables the future of electric vehicles

Aug 17, 2022 · Silicon carbide is affecting the entire electric vehicle industry and will be at the heart of electronics along with gallium nitride, another wide-bandgap material. During APEC,

Get Started

Tesla''s Innovative Power Electronics: The Silicon

Feb 17, 2021 · Today, silicon insulated-gate bipolar transistors (Si IGBTs) dominate the medium power range, including electric vehicle inverters. We are

Get Started

Tesla rattles investors and suppliers over SiC in EVs

Mar 4, 2023 · Initially, Patel tweeted the 75% silicon carbide reduction could be "bad bad bad" for several schipmakers, but he and many other analysts

Get Started

6 FAQs about [Silicon Carbide Inverter Price]

What is a silicon carbide inverter?

Our 800-Volt Silicon Carbide Inverter for Electrified Vehicles uses an innovative, double-side cooled silicon carbide (SiC) based power switch that delivers the higher power densities and efficiencies needed to extend battery range and performance, and reduce costs.

Why should you choose a silicon carbide inverter for electric vehicles?

Studies show the major factors holding consumers back from purchasing a plug-in hybrid (PHEV) or battery electric vehicle (BEV) are battery range, charging convenience and costs. Our solution for this challenge? The 800-Volt Silicon Carbide Inverter for Electrified Vehicles.

Can a silicon carbide inverter be scaled?

Lastly, the 800-Volt Silicon Carbide Inverter for Electrified Vehicles can be scaled and adapted to lower and higher voltage systems, giving manufacturers much-needed economies of scale managing the multiple voltages and current levels required by PHEVs and BEVs.

What are the advantages of silicon carbide for industrial motor drive inverters?

This article discusses the advantages of Silicon Carbide for industrial motor drive inverters over the silicon counter-part of such devices. In many power electronics-based applications such as industrial motor control units, requirements like space, weight and efficiency play an increasing role.

What is the 800-volt silicon carbide inverter for electric vehicles?

The 800-Volt Silicon Carbide Inverter for Electrified Vehicles, with its breakthrough features, is a game-changer for the industry that manufacturers can use to create the compelling buying propositions that lead to greater acceptance and therefore sales for these new means of mobility.

How do silicon carbide inverters differ in size and weight?

As a consequence, silicon carbide-based inverter designs are almost half the size and weight of silicon-based inverter designs. This is due to the increased switching frequency of silicon carbide inverters, which is two to three times higher than ordinary silicon inverters.

Related Articles

-

Solar Silicon Carbide Inverter

Solar Silicon Carbide Inverter

-

Price of crystalline silicon photovoltaic modules in Mumbai India

Price of crystalline silicon photovoltaic modules in Mumbai India

-

220b inverter connected to silicon rectifier generator

220b inverter connected to silicon rectifier generator

-

How much is the inverter price in Amsterdam

How much is the inverter price in Amsterdam

-

Factory price 4000 w inverter in Canada

Factory price 4000 w inverter in Canada

-

Factory price hybrid inverter in Mumbai

Factory price hybrid inverter in Mumbai

-

China factory price 5 5 kw inverter exporter

China factory price 5 5 kw inverter exporter

-

Inverter price l1000w

Inverter price l1000w

-

Samoa lithium battery inverter price

Samoa lithium battery inverter price

-

Cheap factory price 2 4 kw inverter Seller

Cheap factory price 2 4 kw inverter Seller

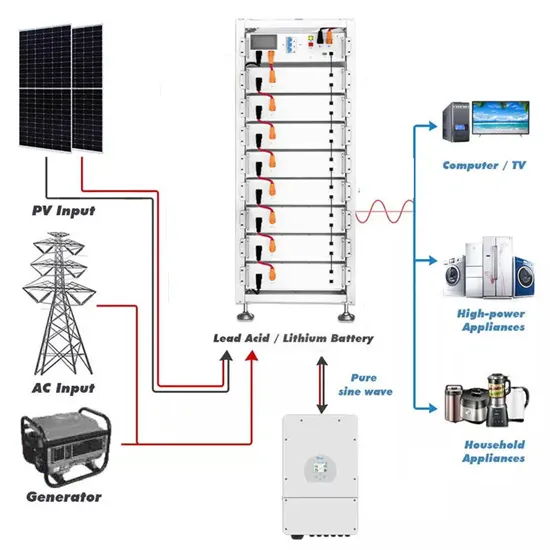

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

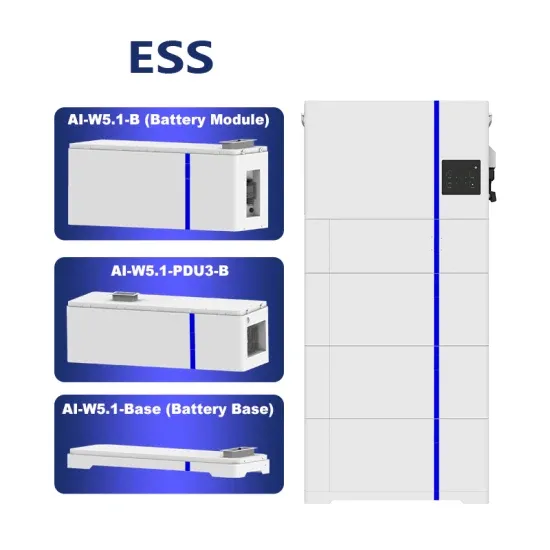

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.