What are the advantages and disadvantages of cylindrical batteries

Lithium batteries can be divided into cylindrical batteries, square batteries, and soft pack batteries according to their packaging forms. Although square batteries are currently the mainstream of

Get Started

Do You Know Why Lithium Batteries are Mostly Cylindrical and Square

Apr 23, 2025 · Whether it is a mobile phone, an electric vehicle or an energy storage power station, the shape of lithium batteries is mostly cylindrical or square. These two designs may

Get Started

The production process of lithium batteries is divided into

The production of the lithium-ion battery cell consists of three main process steps: electrode manufacturing, cell assembly and cell finishing. Electrode production and cell finishing are

Get Started

Different Packing form of battery

Cylindrical battery: long development time, the most mature technologyCylindrical batteries have the longest development time, and the technology is the most mature, with a high degree of

Get Started

What are cylindrical lithium batteries available?

Cylindrical lithium batteries are divided into three types: lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, and a mixture of cobalt and manganese. The ternary material

Get Started

Innovative Polymer Battery Solutions

At present, there are three main packaging forms of lithium battery, that is, cylinder, square and soft package. Different packaging structures mean

Get Started

Which is better for Li-ion battery soft pack or hard pack?

Sep 14, 2021 · Which is better for Li-ion battery soft pack or hard pack? Why do lithium batteries need to be divided into soft and hard packs?

Get Started

What are the differences between cylindrical lithium batteries

The structure difference between cylindrical lithium battery and square lithium battery Cylindrical lithium battery is divided into different systems of lithium iron phosphate, lithium cobalt oxide,

Get Started

The difference between cylindrical lithium batteries and square lithium

Cylindrical lithium batteries are divided into three different systems: lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, cobalt manganese mixture, and ternary materials. The

Get Started

Structure, Pros and Cons of Square Lithium

Nov 14, 2024 · Square lithium batteries, also known as prismatic batteries, feature a rectangular shape that allows for efficient space utilization in various

Get Started

Cylindrical lithium battery classification and

May 17, 2023 · Cylindrical lithium batteries are divided into different systems of lithium iron phosphate,lithium cobaltate,lithium manganate,cobalt-manganese

Get Started

Lithium Battery Production Process | Prominer (Shanghai)

Lamination (equipment: laminator) is the lamination of single pole pieces made in the die cutting process into lithium-ion battery cells, mainly used in the production of flexible battery.

Get Started

Lithium batteries can be divided into three types based on

Lithium batteries can be divided into three types based on their packaging form: square, cylindrical, and pouch. #SquareBatteries Square lithium batteries are typically manufactured

Get Started

What is a cylindrical lithium battery? What are the

Cylindrical lithium batteries are divided into three different systems: lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, cobalt manganese mixture, and ternary materials. The

Get Started

Complete List of Cylindrical Lithium Battery Models.

Cylindrical lithium batteries are divided into different systems such as lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, cobalt manganese hybrid, and ternary

Get Started

Cylindrical vs. Prismatic vs. Li-Po Battery: Key Differences

Feb 29, 2024 · Cylindrical batteries are divided into lithium iron phosphate, cobalt oxide, manganate, cobalt oxide, and ternary systems. The shell is divided into two types: steel shell

Get Started

Lithium batteries can be divided into three types based on

Jul 29, 2025 · Lithium batteries can be divided into three types based on their packaging form: prismatic, cylindrical, and pouch. #Prismatic Cell Square lithium batteries are typically

Get Started

The difference between cylindrical lithium battery and square lithium

Nov 8, 2021 · Cylindrical lithium batteries are divided into different systems such as lithium iron phosphate, lithium cobalt oxide, lithium manganate, cobalt-manganese hybrid, and ternary

Get Started

production process of Lithium Battery – semco

Lithium batteries can be divided into cylindrical batteries, square batteries and soft pack batteries according to their shape, and their production processes

Get Started

What are cylindrical lithium batteries and their advantages?

Dec 11, 2023 · 1、 What is a cylindrical lithium battery? Cylindrical lithium batteries are divided into three different systems: lithium iron phosphate, lithium cobalt oxide, lithium manganese

Get Started

Introduction to the three major packaging

Apr 17, 2025 · Lithium-ion batteries are divided into square batteries, soft-pack batteries, and cylindrical batteries according to different packaging processes.

Get Started

The structure and advantages and disadvantages

Jun 19, 2023 · Lithium-ion batteries are divided into square lithium batteries (such as commonly used mobile phone battery cells), cylindrical lithium batteries

Get Started

A detailed comparison of BYD battery Prismatic

Nov 24, 2024 · Based on the packaging form, lithium batteries can be divided into three forms: square, cylindrical and soft-pack. The packaging form refers to

Get Started

Comparison of Characteristics between

Lithium batteries can be divided into three packaging forms: cylindrical lithium batteries, square lithium batteries, and soft pack lithium batteries due to their

Get Started

The main classification of lithium-ion batteries

(2) According to the charging method, it can be divided into two categories: non rechargeable and rechargeable. (3) The appearance of lithium batteries can be divided into square

Get Started

Ev car battery pack,ev car battery technology

Dec 8, 2024 · Square is divided into square stacked sheet type, square winding type; cylindrical is divided into cylindrical stacked sheet type, cylindrical winding type. Packaging types are hard

Get Started

Structural comparison between cylindrical lithium batteries and square

Cylindrical lithium-ion batteries are divided into different systems such as lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, cobalt manganese hybrid, and ternary materials.

Get Started

Comparatively Assessing different Shapes of Lithium-ion Battery

Jan 1, 2017 · Different shapes of lithium-ion batteries (LIB) are competing as energy storages for the automobile application. The shapes can be divided into cylindrical and prismatic, whereas

Get Started

The Ultimate Guide to Cylindrical Batteries

Mar 29, 2024 · Cylindrical batteries can be divided into lithium iron phosphate batteries, lithium cobalt oxide batteries, lithium manganate batteries, and

Get Started

Lithium battery equipment industry and key enterprises

Square battery: usually refers to aluminum or steel shell square batteries. Cylindrical batteries: divided into lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, cobalt

Get Started

Pouch vs. Prismatic vs. Cylindrical? Your Lithium Battery Cell

Jul 29, 2025 · When selecting a lithium battery for your RV, marine vessel, or off-grid system, it''s not just about the shape of the cells. The format—prismatic, cylindrical, or pouch—directly

Get Started

Introduction of the Cylindrical Lithium Ion Battery

Apr 13, 2023 · Cylindrical lithium ion batteries are divided into different systems of lithium iron phosphate, lithium cobalt oxide, lithium manganate, cobalt-manganese hybrid, and ternary

Get Started

6 FAQs about [Lithium batteries are divided into cylindrical and square]

What are the different types of cylindrical batteries?

Cylindrical batteries are divided into lithium iron phosphate, cobalt oxide, manganate, cobalt oxide, and ternary systems. The shell is divided into two types: steel shell and polymer. Batteries with different material systems have different advantages. At present, cylindrical batteries are mainly steel-cased cylindrical lithium iron phosphate.

What are the different shapes of lithium-ion batteries?

Pascalstrasse 8-9, 10587 Berlin, Germany Abstract Different shapes of lithium-ion batteries (LIB) are competing as energy storages for the automobile application. The shapes can be divided into cylindrical and prismatic, whereas the prismatic shape can be further divided in regard to the housing stability in Hard-Case and Pouch.

What are the different types of lithium batteries?

The three shapes of lithium batteries will eventually become cylindrical batteries, prismatic batteries and lithium polymer batteries through cylindrical winding, prismatic winding, and prismatic lamination. Different packaging structures mean different characteristics, so what are their differences? Part 1. What’s the cylindrical lithium battery?

What is a cylindrical battery?

At present, cylindrical batteries are mainly steel-cased cylindrical lithium iron phosphate. This cylindrical battery has high capacity, high output voltage, and good charge and discharge cycle performance. Lithium iron phosphate belts are promised to be used in solar lamps, lawn lamps, backup energy sources, power tools, toy models, etc.

What is a lithium polymer battery?

Lithium polymer batteries are currently the least used battery form in electric vehicles. But in fact, we are not unfamiliar with it. Most of the batteries in mobile phones are lithium polymer batteries. The biggest difference between lithium polymer, cylindrical, and prismatic batteries is that their outer casing is made of aluminum-plastic film.

What are the different types of lithium battery packaging?

There are three main mainstream lithium battery packaging forms, namely cylindrical, prismatic, and lithium polymer. The three shapes of lithium batteries will eventually become cylindrical batteries, prismatic batteries and lithium polymer batteries through cylindrical winding, prismatic winding, and prismatic lamination.

Related Articles

-

The new rise of cylindrical lithium batteries

The new rise of cylindrical lithium batteries

-

Application of large cylindrical lithium batteries

Application of large cylindrical lithium batteries

-

Are all cylindrical batteries lithium batteries

Are all cylindrical batteries lithium batteries

-

Can cylindrical lithium batteries be charged

Can cylindrical lithium batteries be charged

-

Uses of cylindrical lithium batteries

Uses of cylindrical lithium batteries

-

Large cylindrical 10ah lithium battery

Large cylindrical 10ah lithium battery

-

Irish company that makes lithium batteries for energy storage

Irish company that makes lithium batteries for energy storage

-

Mauritania 32a cylindrical lithium battery

Mauritania 32a cylindrical lithium battery

-

Moscow lithium battery cylindrical battery

Moscow lithium battery cylindrical battery

-

Large cylindrical lithium battery all sizes

Large cylindrical lithium battery all sizes

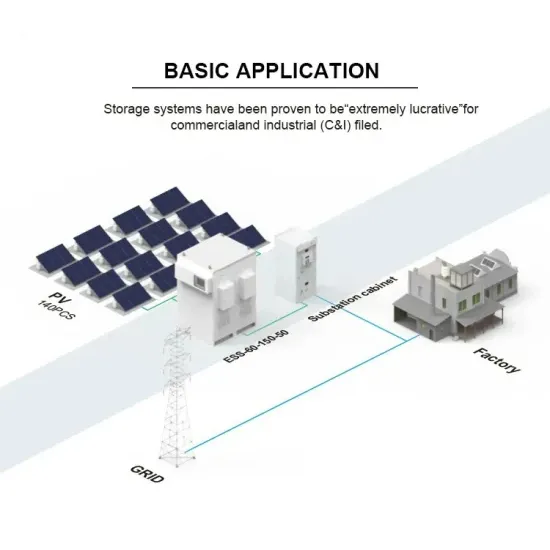

Commercial & Industrial Solar Storage Market Growth

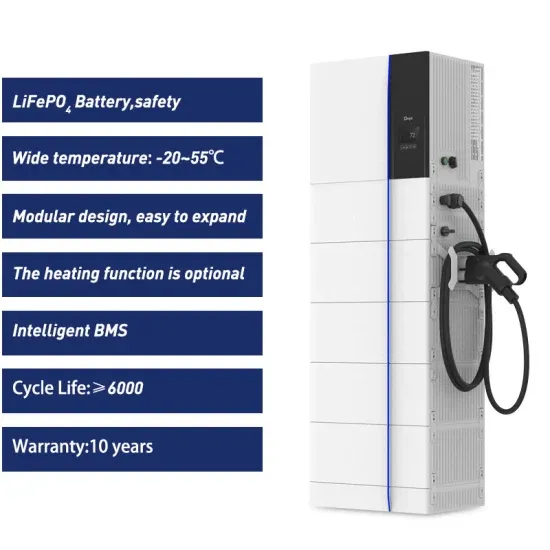

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.