How Do I Choose a BMS for Lithium Batteries? | Redway Tech

Dec 14, 2023 · Choosing a Battery Management System (BMS) for lithium batteries involves considering factors such as voltage compatibility, current rating, cell balancing capabilities,

Get Started

Battery BMS-Vehicle integration: 5 things to know

Jan 25, 2022 · We have listed the characteristics for the "standard" operation of a good BMS system in a lithium battery but everyone is well aware that most

Get Started

What Is a Battery Management System (BMS)?

Aug 7, 2025 · A Battery Management System (BMS) is an essential component in modern battery-powered applications, responsible for monitoring, protecting, and optimizing the

Get Started

How is functional safety defined & implemented

Jul 17, 2023 · Being protected Protection is a primary BMS function. The BMS protects the battery from abusive charging or discharging, excessive

Get Started

Why is a Battery Management System needed in

May 14, 2020 · BMS is an electronic system that manages a rechargeable battery to ensure it operates safely and efficiently. BMS is designed to monitor the

Get Started

Successful Implementation of Battery Monitoring

Feb 6, 2025 · Successful Implementation of Battery Monitoring for Power Plants and Substations There are multiple factors driving utility operators to seek a reliable, validated, and advanced

Get Started

Regulatory Push: How Standards Are Shaping BMS

Jan 13, 2025 · EV batteries are very critical & expensive components and account for up to 30-40% of an EV''s overall cost. Hence it presents an unprecedented emphasis on the

Get Started

How Do I Choose a BMS for a Lithium-Ion Battery?

Oct 31, 2024 · Choosing the right Battery Management System (BMS) for a lithium-ion battery is crucial for ensuring safety, performance, and longevity. A BMS monitors and manages the

Get Started

Battery Management System Hardware

This paper focuses on the hardware aspects of battery management systems (BMS) for electric vehicle and stationary applications. The purpose is giving an

Get Started

Battery Management System (BMS) for Efficiency and Safety

Jan 5, 2025 · Learn How Battery Management System (BMS) Optimizes Efficiency and Safety in Electric Vehicles, Energy Storage, and Electronics.

Get Started

Guide to BMS Testing: Ensuring Battery Safety

Feb 14, 2025 · Learn everything about Battery Management System (BMS) testing, including safety, performance, communication, and durability tests.

Get Started

Comparison Overview: How to Choose from

Aug 22, 2023 · We provide a detailed comparison of the types of battery management system based on five key categories and guidance on selecting

Get Started

A Deep Dive into Battery Management System

Aug 24, 2023 · The battery management system architecture is a sophisticated electronic system designed to monitor, manage, and protect batteries.

Get Started

What Amp BMS Do I Need? Sizing Battery Management

Each BMS is designed to cater to different battery types and their unique requirements. To help you make an informed decision, here are some top recommended BMSs for different battery

Get Started

Best Battery Bms [Updated On: August 2025]

4 days ago · When consulting with DIY enthusiasts and engineers about their battery management needs, one requirement consistently topped their list: reliable, precise

Get Started

Review of Battery Management Systems (BMS)

Mar 15, 2021 · It further studies current gaps in respect to the safety requirements and performance requirements of BMS by focusing mainly on the electric

Get Started

Battery Management System BMS Explained:

Jun 4, 2025 · A battery management system BMS is an electronic control unit designed to monitor, regulate, and protect battery packs. Fundamentally, it

Get Started

Types of International Battery Safety Standards

Oct 3, 2023 · Battery safety standards refer to regulations and specifications established to ensure the safe design, manufacturing, and use of batteries.

Get Started

Key points and requirements of electric vehicle

Jun 10, 2025 · BMS PCB design plays a key role in ensuring battery performance, safety and reliability. This article briefly explains the main points of electric

Get Started

Do I Need a BMS for Lithium-Ion Batteries? Benefits and

Apr 15, 2025 · A Battery Management System (BMS) protects lithium-ion batteries from overcharging by monitoring their voltage and controlling the charge process. The BMS

Get Started

What is a Battery Management System (BMS)?

May 5, 2025 · A Battery Management System (BMS) safeguards lithium-ion batteries by monitoring voltage, current, and temperature, preventing

Get Started

Battery Management System Requirements

Jul 12, 2023 · Depending on whether your battery pack or system (single-unit multicell batteries and multiple battery architectures) is the primary power

Get Started

BMS Requirements

Tailoring a Battery Management System (BMS) to meet application-specific prerequisites assumes paramount importance, as these requirements wield authority over the functionality

Get Started

What Is a BMS Battery? A Complete Guide for Beginners and

Apr 23, 2025 · Why Do Lithium Batteries Need a BMS? Lithium-ion batteries are known for their high energy density, light weight, and long cycle life. However, they also come with strict

Get Started

How does lithium battery BMS determine the

May 1, 2025 · This article will explore the functions, working principles, application areas, future development trends, and challenges of lithium battery BMS in

Get Started

BMS Design: Essential Components and Modern

Jul 19, 2024 · Conclusion Battery Management Systems are indispensable for the safe and efficient operation of rechargeable batteries in a wide range of

Get Started

Safety Standards For Battery Management (BMS) In Electric

Dec 25, 2024 · ISO 26262 is a key standard for automotive functional safety, focusing on electrical and electronic systems, including BMS. It outlines safety requirements to manage risks

Get Started

BMS Requirements

Accuracy, response time, and robustness are three crucial performance criteria for a BMS that are covered in this section. Accuracy within a Battery Management System (BMS) signifies the

Get Started

Battery-Management-System Requirements

Jan 20, 2015 · The methods and algorithms we discuss would typically be implemented by a battery-management system or BMS. A BMS is an embedded system (purpose-built

Get Started

What is a Battery Management System? Complete Guide to BMS

Aug 3, 2025 · A Battery Management System (BMS) is an electronic control unit that monitors and manages rechargeable battery packs to ensure safe operation, optimal performance, and

Get Started

A review of battery energy storage systems and advanced battery

May 1, 2024 · Battery management systems (BMS) are crucial to the functioning of EVs. An efficient BMS is crucial for enhancing battery performance, encompassing control of charging

Get Started

What Is a Lithium Battery Management System and How

Apr 23, 2025 · A Lithium Battery Management System (BMS) monitors voltage, temperature, and current to prevent overcharging, overheating, and short circuits. By balancing cell voltages and

Get Started

Do I Need a BMS for Lithium-Ion Batteries? Benefits and

Apr 15, 2025 · In summary, selecting the right BMS for lithium-ion batteries involves evaluating these features to match specific requirements. Prioritizing features according to application

Get Started

6 FAQs about [What are the requirements of BMS for batteries]

What are the performance criteria for a battery management system (BMS)?

Accuracy, response time, and robustness are three crucial performance criteria for a BMS that are covered in this section. Accuracy within a Battery Management System (BMS) signifies the system's capacity to deliver exact measurements and maintain control.

What are battery management system requirements?

The battery management system requirements define the operational and performance criteria for your BMS board design that is relevant for all BMS types and applications. Battery management system architectures can be relatively simple or very complex and include the following types: Here, each battery pack section has its own BMS unit.

How to design a battery management system (BMS)?

In the process of designing a Battery Management System (BMS), it becomes imperative to possess a comprehensive understanding of and account for the specifications and operational parameters of the batteries under its management.

What is accuracy in a battery management system (BMS)?

Accuracy within a Battery Management System (BMS) signifies the system's capacity to deliver exact measurements and maintain control. A fundamental duty of the BMS is to determine the State of Charge (SOC) and State of Health (SOH) of the battery.

What are the benefits of a battery management system (BMS)?

An optimized BMS ensures: Extended Battery Life: By preventing overcharging or undercharging, BMS reduces battery wear and tear, maximizing the usable lifespan. Energy Efficiency: Efficiently charging and discharging the battery minimizes energy waste, improving overall performance of the system.

What are functional safety standards in battery management systems (BMS)?

01. Functional Safety Standards (ISO 26262) Functional safety standards ensure that safety-related functionality in Battery Management Systems (BMS) is maintained throughout its lifecycle, mitigating risks that could compromise the system’s reliability and safety.

Related Articles

-

What do BMS and PACK mean in lithium batteries

What do BMS and PACK mean in lithium batteries

-

What are the requirements for energy storage cabinet safety solutions

What are the requirements for energy storage cabinet safety solutions

-

What are the photovoltaic power generation solutions for lead-acid batteries in communication base stations

What are the photovoltaic power generation solutions for lead-acid batteries in communication base stations

-

What are the energy storage batteries exported from Dushanbe

What are the energy storage batteries exported from Dushanbe

-

What does BMS battery system mean

What does BMS battery system mean

-

What are the requirements for solar energy systems

What are the requirements for solar energy systems

-

What is the use of lithium-ion batteries for communication base stations

What is the use of lithium-ion batteries for communication base stations

-

Latest material requirements for energy storage batteries

Latest material requirements for energy storage batteries

-

What is the best inverter model for batteries

What is the best inverter model for batteries

-

What types of energy storage batteries will there be in the future

What types of energy storage batteries will there be in the future

Commercial & Industrial Solar Storage Market Growth

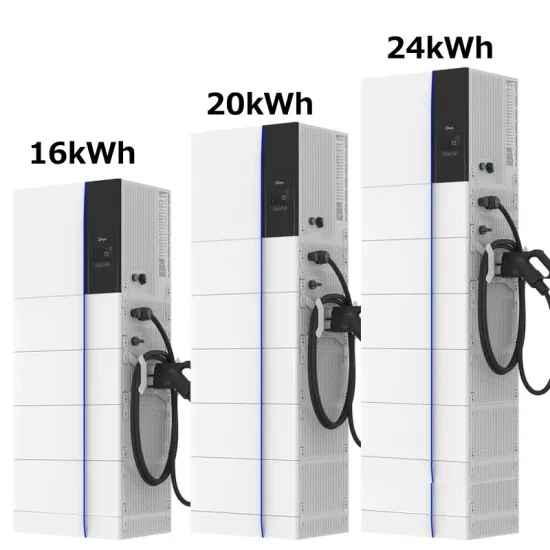

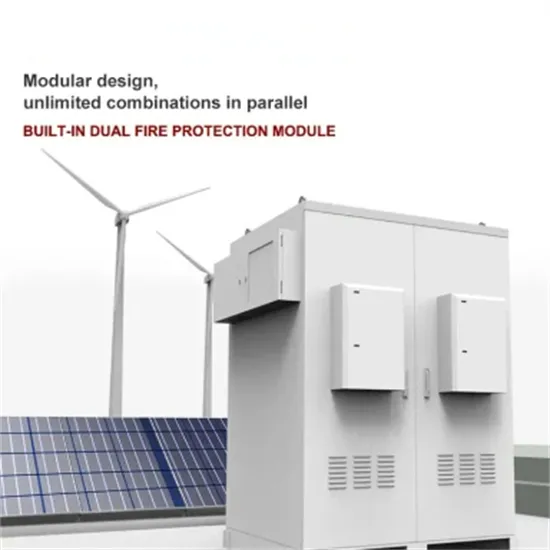

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.