Precise Potential Tuning for Polymer-Mediated Aqueous Redox Flow

Dec 13, 2023 · Precise Potential Tuning for Polymer-Mediated Aqueous Redox Flow Battery with Lithium Iron Phosphate as Target Cathode. A highly hydrophilic ferrocene-containing polymer

Get Started

Status and prospects of lithium iron phosphate

Sep 23, 2024 · Lithium iron phosphate (LiFePO4, LFP) has long been a key player in the lithium battery industry for its exceptional stability, safety, and cost-effectiven

Get Started

What is the Electrolyte in a Lithium Iron

Jul 6, 2024 · The electrolyte in a Lithium Iron Phosphate battery is a crucial component that significantly influences the battery''s performance, safety, and

Get Started

An overview on the life cycle of lithium iron phosphate:

Apr 1, 2024 · Lithium Iron Phosphate (LiFePO4, LFP), as an outstanding energy storage material, plays a crucial role in human society. Its excellent safety, low cos

Get Started

LifePO4 BMS: The Expert Guide

A LifePO4 battery management system is a specialized electronic device that manages lithium iron phosphate battery packs. It monitors individual cell voltages, temperatures, and the overall

Get Started

Liquid flow batteries are rapidly penetrating into hybrid

Oct 12, 2024 · This year, "lithium iron phosphate + flow battery" and "lithium iron phosphate + flywheel" have shown an accelerated growth trend in the hybrid energy storage market.

Get Started

A Study on effect of coolant flow rate on steady-state

A Study on effect of coolant flow rate on steady-state thermal resistance of a 48 V lithium iron phosphate battery pack under dynamic duty cycles

Get Started

Precise Potential Tuning for Polymer-Mediated Aqueous Redox Flow

Dec 13, 2023 · A highly hydrophilic ferrocene-containing polymer with an ammonium group was synthesized as a polymer mediator for redox targeting flow batteries (RTFB) by using LiFePO4

Get Started

Exploring sustainable lithium iron phosphate cathodes for Li

Transformation of lithium, iron, and phosphorus ores into battery-grade precursors. Key steps in purification and refining processes. Overview of sustainable purified phosphoric acid

Get Started

5 Battery Technologies That Could Replace Lithium-Ion in EVs

Jul 17, 2025 · Cobalt-free lithium-ion batteries, such as those using lithium-iron-phosphate (LFP) or organic cathodes, operate like standard LIBs. Lithium ions move between the anode and

Get Started

Lithium Iron Phosphate (LiFePO4) Battery Manufacturing

Aug 18, 2025 · The Raw Materials: The journey to creating a LiFePO4 battery begins with sourcing high-quality raw materials. Key components include lithium carbonate, iron

Get Started

Lithium-iron Phosphate (LFP) Batteries: A to Z

Mar 28, 2023 · Lithium-ion batteries have become the go-to energy storage solution for electric vehicles and renewable energy systems due to their high

Get Started

Lithium-ion battery, sodium-ion battery, or redox-flow battery

Oct 1, 2023 · Lithium-iron phosphate batteries (LFPs) are the most prevalent choice of battery and have been used for both electrified vehicle and renewable energy applications due to their

Get Started

Understanding Lithium-Ion and Vanadium

March 19, 2025 Understanding Lithium-Ion and Vanadium Redox Flow: Choosing the Right Battery for Your Needs In the rapidly evolving world of energy

Get Started

Life cycle assessment of lithium nickel cobalt manganese

Aug 1, 2022 · In this paper, lithium nickel cobalt manganese oxide (NCM) and lithium iron phosphate (LFP) batteries, which are the most widely used in the Chinese electric vehicle

Get Started

INTRODUCTION TO LITHIUM IRON PHOSPHATE

Figure: Lithium iron phosphate batteries achieve around 2,000 cycles, while lead-acid batteries only go through 300 cycles on average - a clear diference in longevity.

Get Started

Recent Advances in Lithium Iron Phosphate

Dec 1, 2024 · Lithium iron phosphate (LFP) batteries have emerged as one of the most promising energy storage solutions due to their high safety, long cycle

Get Started

(PDF) Recent Advances in Lithium Iron Phosphate Battery

Dec 1, 2024 · This review paper provides a comprehensive overview of the recent advances in LFP battery technology, covering key developments in materials synthesis, electrode

Get Started

Slurry Based Lithium-Ion Flow Battery with a

Jun 28, 2023 · Slurry based lithium-ion flow battery has been regarded as an emerging electrochemical system to obtain a high energy density and design

Get Started

Exploring sustainable lithium iron phosphate cathodes for Li

Lithium iron phosphate (LFP) cathodes are gaining popularity because of their safety features, long lifespan, and the availability of raw materials. Understanding the supply chain from mine

Get Started

LiFePO4 vs. Lithium Ion Batteries: What''s the Best Choice for

The battery industry has advanced rapidly in recent years, making superior technologies more affordable. Lithium iron phosphate (also known as LiFePO4 or LFP) is the latest development

Get Started

Recent Advances in Lithium Iron Phosphate Battery

Dec 1, 2024 · This review paper aims to provide a comprehensive overview of the recent advances in lithium iron phosphate (LFP) battery technology, encompassing materials

Get Started

Things You Should Know About LFP Batteries | EcoFlow US

Lithium Iron Phosphate batteries are popular for solar power storage and electric vehicles. Find out what things you should know about LFP batteries.

Get Started

5 Key Differences Between Flow Batteries and

Dec 13, 2021 · The differences between flow batteries and lithium ion batteries are cost, longevity, power density, safety and space efficiency.

Get Started

8 LFP Battery Companies to Watch

Dec 20, 2022 · Lithium iron phosphate (LFP) batteries are a type of lithium-ion battery that has gained popularity in recent years due to their high energy

Get Started

Introduction guide of flow battery

Aug 16, 2025 · At present, China''s largest flow battery demonstration project has achieved 100 MW/400 MWh. At present, there are three technical routes for

Get Started

(PDF) Global material flows of lithium i Global

Nov 10, 2021 · A material flow analysis (MFA) model for a single year (2018) to understand the global flows of lithium from primary extraction to lithium-ion

Get Started

How Is the Manufacturing Process of Lithium Iron Phosphate Batteries

Feb 21, 2025 · The manufacturing process of lithium iron phosphate (LiFePO4) batteries involves several critical steps that ensure high performance and safety. These batteries are known for

Get Started

Everything You Need to Know About LiFePO4 Battery Cells: A

Apr 18, 2025 · LiFePO4 is a type of lithium-ion battery distinguished by its iron phosphate cathode material. Unlike traditional lithium-ion batteries, LiFePO4 batteries offer superior thermal

Get Started

Thermal Characteristics of Iron Phosphate Lithium Batteries

Mar 30, 2024 · Limited research has been conducted on the heat generation characteristics of semi-solid-state LFP (lithium iron phosphate) batteries.This study investigated commercial

Get Started

Phase Transitions and Ion Transport in Lithium

Jun 10, 2024 · Lithium iron phosphate (LiFePO 4, LFP) serves as a crucial active material in Li-ion batteries due to its excellent cycle life, safety, eco

Get Started

6 FAQs about [Lithium iron phosphate battery flow battery]

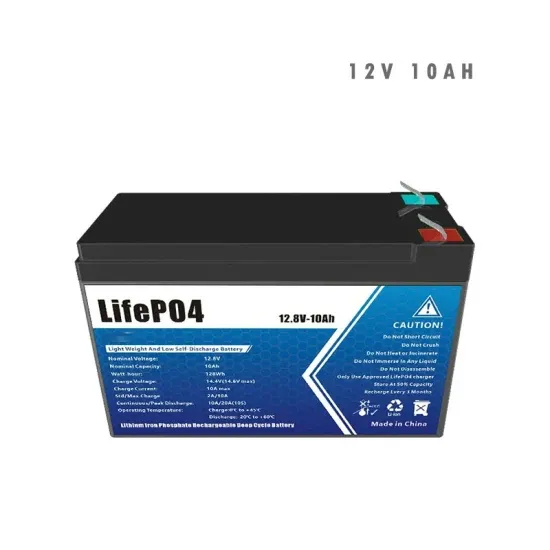

What is lithium iron phosphate battery?

Lithium iron phosphate battery has a high performance rate and cycle stability, and the thermal management and safety mechanisms include a variety of cooling technologies and overcharge and overdischarge protection. It is widely used in electric vehicles, renewable energy storage, portable electronics, and grid-scale energy storage systems.

Is lithium iron phosphate a suitable cathode material for lithium ion batteries?

Since its first introduction by Goodenough and co-workers, lithium iron phosphate (LiFePO 4, LFP) became one of the most relevant cathode materials for Li-ion batteries and is also a promising candidate for future all solid-state lithium metal batteries.

Are lithium iron phosphate batteries a good energy storage solution?

Lithium iron phosphate (LFP) batteries have emerged as one of the most promising energy storage solutions due to their high safety, long cycle life, and environmental friendliness.

What is a lithium iron phosphate battery assembly process?

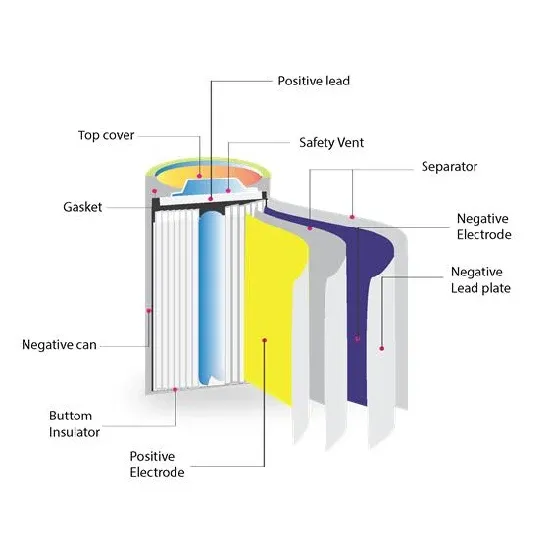

In lithium iron phosphate batteries, the assembly process usually includes the preparation of components such as positive electrode sheets, negative electrode sheets, diaphragms, and electrolytes.

What is a slurry based lithium-ion flow battery?

A slurry based lithium-ion flow battery is a type of battery that uses a liquid slurry of lithium iron phosphate (LiFePO4 or LFP) as its electrolyte. This battery features a serpentine flow field and a porous carbon felt electrode design. The schematic illustration shows an example of this concept using LFP slurry.

Does lithium iron phosphate affect battery performance?

In addition, lithium iron phosphate has some other problems. Its low-temperature performance is not good; in a low-temperature environment, the battery performance will drop significantly, affecting the range and the usefulness of the battery.

Related Articles

-

Norway energy storage lithium iron phosphate battery

Norway energy storage lithium iron phosphate battery

-

Does the lithium iron phosphate battery have a cylindrical shape

Does the lithium iron phosphate battery have a cylindrical shape

-

60v lithium iron phosphate battery pack

60v lithium iron phosphate battery pack

-

UPS and lithium iron phosphate battery pack

UPS and lithium iron phosphate battery pack

-

Portable energy storage lithium iron phosphate battery

Portable energy storage lithium iron phosphate battery

-

Lithium iron phosphate battery for base stations

Lithium iron phosphate battery for base stations

-

Bogota lithium iron phosphate battery energy storage container price

Bogota lithium iron phosphate battery energy storage container price

-

Structural design of lithium iron phosphate battery station cabinet

Structural design of lithium iron phosphate battery station cabinet

-

Bare charging of lithium iron phosphate battery pack

Bare charging of lithium iron phosphate battery pack

-

Communication base station lithium iron phosphate battery with inverter

Communication base station lithium iron phosphate battery with inverter

Commercial & Industrial Solar Storage Market Growth

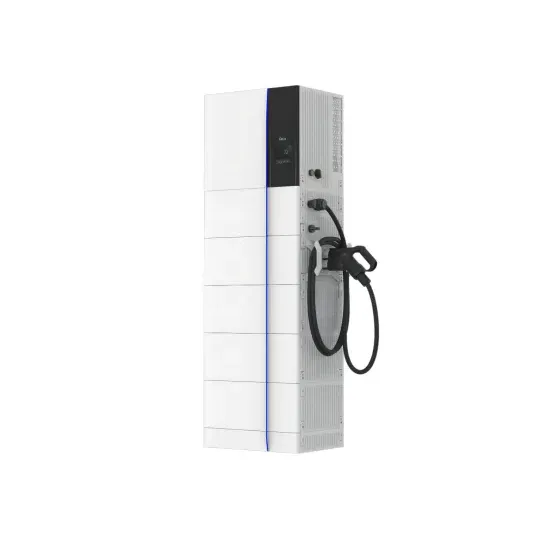

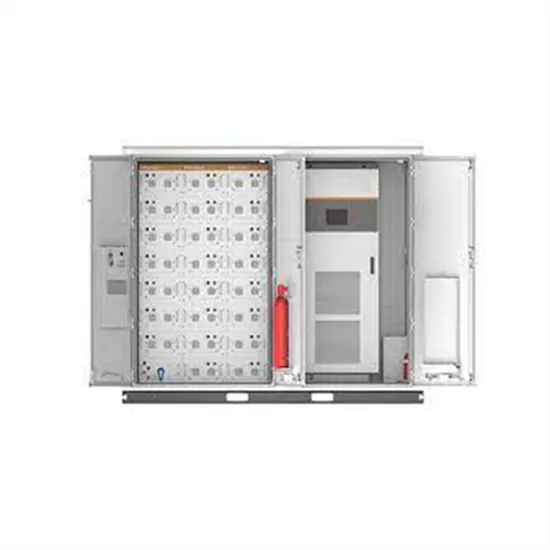

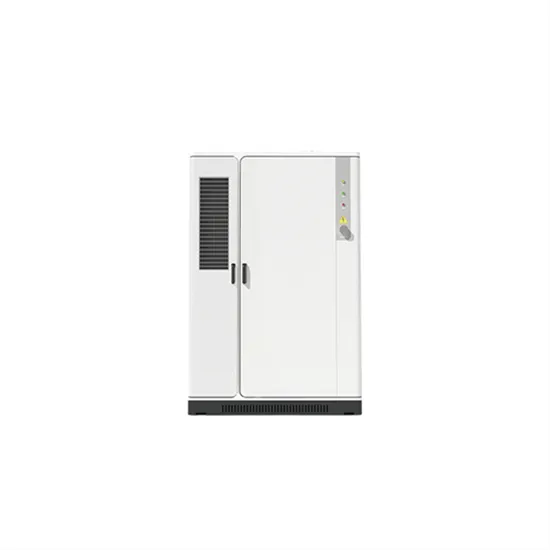

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.