Optimized lead-acid grid architectures for automotive lead-acid

Mar 10, 2021 · A variety of technological approaches of lead-acid batteries have been employed during the last decades, within distinguished fabrication features of electrode grid composition,

Get Started

Communication Base Station Lead-Acid Battery: Powering

In an era where lithium-ion dominates headlines, communication base station lead-acid batteries still power 68% of global telecom towers. But how long can this 150-year-old technology

Get Started

Base Stations

Jul 23, 2025 · The present-day tele-space is incomplete without the base stations as these constitute an important part of the modern-day scheme of wireless

Get Started

有道翻译_文本、文档、、在线即时翻译

有道翻译提供即时免费的中文、英语、日语、韩语、法语、德语、俄语、西班牙语、葡萄牙语、越南语、印尼语、意大利语、荷兰语、泰语全文翻译、翻译、文档翻译、PDF翻译、DOC

Get Started

Lead Acid Battery | Construction, Working and

Jan 2, 2025 · Lead acid battery is a type of rechargeable battery that uses lead plates and sulphuric acid to store and produce electrical energy. It works

Get Started

Tower base station energy storage battery

According to the requirement of power backup and energy storage of tower communication base station, combined with the current situation of decommissioned power battery, this paper

Get Started

Telecom Base Station Backup Power Solution:

Jun 5, 2025 · Designing a 48V 100Ah LiFePO4 battery pack for telecom base stations requires careful consideration of electrical performance, thermal

Get Started

A Guide To Sealed Lead Acid Battery Construction

A complete guide to the construction of a sealed lead acid battery, including battery terminals, electrolyte, casing and battery seperators. Find out more

Get Started

Base station lead-acid battery access unit

elecom batteries is the lead-acid battery. These rechargeable batteries are not 100% sealed but ply power in the event of a mains failure. It includes a speaker (mounted on the fron

Get Started

Telecom Backup: Lead-Acid Battery Use

Jul 1, 2025 · This article explores the role of lead-acid batteries in telecom backup systems, their advantages, applications, and future considerations.

Get Started

how to make lead acid storage battery › › Basengreen Energy

In this article, we will discuss the step-by-step process of making a lead acid storage battery. To make a lead acid storage battery, you will need the following materials: – Lead plates –

Get Started

A Complete Guide to Lead Acid BMS

Sep 24, 2024 · Conclusion In summary, a Lead-Acid BMS is an essential tool for anyone relying on lead-acid batteries, providing safety, reliability, and

Get Started

What equipment is needed to build a lead-acid battery

Jun 6, 2023 · To build a lead-acid battery production factory, a factory needs to have equipment for making plates, equipment for assembling cells or modules, and equipment for forming cells

Get Started

From communication base station to emergency

Taking the lead-acid battery pack of a 48V communication base station as an example, it is commonly configured with multiple 12V lead-acid batteries in

Get Started

What is a lead acid battery? – BatteryGuy Knowledge Base

May 3, 2024 · The process starts with the fabrication of lead plates. In some types of lead acid batteries lead alone is not strong enough and so other metals such as tin are added to give

Get Started

Lead acid battery construction

Oct 25, 2024 · Lead acid batteries are a simple technology, and have changed little since the 1800s. Battery banks for offgrid use are expensive, making

Get Started

Optimization of Communication Base Station

Dec 7, 2023 · In the communication power supply field, base station interruptions may occur due to sudden natural disasters or unstable power supplies. This

Get Started

Build a Simple Lead Acid Battery at Home

Nov 29, 2021 · We explain how to build a simple lead acid battery at home. You must wear protection before you start, and work in well ventilated space.

Get Started

Lead Acid

May 17, 2024 · Battery University monitors the comments and understands the importance of expressing perspectives and opinions in a shared forum. However, all communication must be

Get Started

VIDEO – How a flooded lead acid battery is made

The flooded lead acid battery is only one member of the lead acid family. There are also Valve Regulated Lead Acid, Sealed Lead Acid Gel and Absorbent Glass Mat Lead Acid variants.

Get Started

Lead Acid Battery Charger Circuit

May 30, 2020 · In this tutorial, I will tell you the best way to build a basic Lead Acid Battery Charger Circuit. This circuit utilizes to charge Rechargeable 12V

Get Started

How to make New Lead Acid Battery at home,

Dec 15, 2021 · How to make New Lead Acid Battery at home, 220Ah Lead Acid Battery Making– In article, you will learn how to make a new lead acid battery

Get Started

Wireles Battery Monitoring, Lead Acid

G-TH WL wireless battery monitoring system adopts a new generation of ZigBee wireless communication technology, which reduces on-site wiring by half and

Get Started

DIY Lead Acid Battery Charger : 8 Steps

DIY Lead Acid Battery Charger: Actually this could be used to charge any sort of battery where you want a constant current and a constant voltage. In this

Get Started

How to make Lead Acid Battery at Home and

Oct 14, 2021 · How to make Lead Acid Battery at Home and Required Tools explained- In this tutorial, you will learn how to make and repair any type of

Get Started

Use of Batteries in the Telecommunications Industry

Mar 18, 2025 · Who or What is ATIS? The Alliance for Telecommunications Industry Solutions is an organization that develops standards and solutions for the ICT (Information and

Get Started

Building a battery bank using amp hours batteries

May 3, 2024 · In this article we''ll look at different ways to build a battery bank (and ways not to) for amp hour rated batteries (and ways not to). In the illustrations we use sealed lead acid

Get Started

12 Volt Lead Acid Battery Charger Circuit

Aug 4, 2022 · In this tutorial, I will tell you the best way to build a basic Lead Acid Battery Charger Circuit. This circuit utilizes to charge Rechargeable 12V Lead

Get Started

Here''s How You Can Make A New Lead Acid

May 25, 2014 · Alright, so how do you build a battery from an existing dead battery and more importantly why does the battery die? Which component

Get Started

How to Make Lead Acid Battery Electrolyte Solution

Feb 4, 2025 · Learn how to make lead acid battery electrolyte solution safely. Easy steps and tips to ensure proper mixture for your battery''s performance.

Get Started

6 FAQs about [How to build a lead-acid battery for a wireless communication base station]

How does a lead acid battery work?

Lead acid battery is a type of rechargeable battery that uses lead plates and sulphuric acid to store and produce electrical energy. It works through a chemical reaction between the lead and electrolyte, which creates electricity when connected to a load. What are the characteristics of lead acid battery?

How to build a lead acid battery at home?

You must work in ventilated space to disperse fumes when you build this simple lead acid battery at home. Put on your plastic gloves and face protection first. Then attach two suitable size lead sheets to the inside of one of the plastic containers. Those sheets should be a ½ inch above the base, and extend above the rim to attach crocodile clips.

What happens when lead plates are placed in acid?

When the lead plates are placed in the acid, a chemical reaction takes place, which produces electricity. This process can be reversed to recharge the battery. When several battery cells are joined together in series, parallel or a mix of both, they form a complete battery.

What are lead acid batteries used for?

Lead Acid batteries are used for variety of application such as: For petrol motor car starting and ignition. As a source of power supply in telephone exchange, laboratories and broadcasting stations. For local lighting of generating and substations during odd times and break down. For starting rotary converters in substations.

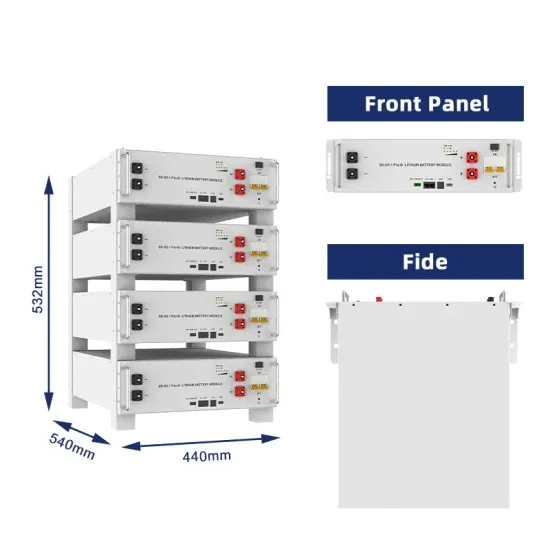

What makes a telecom battery pack compatible with a base station?

Compatibility and Installation Voltage Compatibility: 48V is the standard voltage for telecom base stations, so the battery pack’s output voltage must align with base station equipment requirements. Modular Design: A modular structure simplifies installation, maintenance, and scalability.

What type of electrolyte is used in a lead-acid battery?

Electrolyte: Electrolyte used in a lead-acid battery is a dilute sulphuric acid solution. It is usually a mix of three parts water and one part sulphuric acid. Container: Plates and electrolyte are placed in a container which may be made of vulcanised rubber or moulded hard rubber, ceramic, glass or celluloid. Container is sealed at the top.

Related Articles

-

How to build a lithium-ion battery for a communication base station

How to build a lithium-ion battery for a communication base station

-

How to connect the battery cabinet communication base station to the power supply

How to connect the battery cabinet communication base station to the power supply

-

5g communication base station lead-acid battery construction

5g communication base station lead-acid battery construction

-

Vientiane Communication Base Station Lead-acid Battery Photovoltaic Power Generation External Machine Cooling

Vientiane Communication Base Station Lead-acid Battery Photovoltaic Power Generation External Machine Cooling

-

How about the lithium battery of communication base station

How about the lithium battery of communication base station

-

How many communication base station battery energy storage systems are there in Samoa

How many communication base station battery energy storage systems are there in Samoa

-

How to build a green communication base station project

How to build a green communication base station project

-

Chad 5g communication base station lead-acid battery company

Chad 5g communication base station lead-acid battery company

-

How to protect communication base station battery equipment

How to protect communication base station battery equipment

-

Mexico multifunctional communication base station lead-acid battery supplier

Mexico multifunctional communication base station lead-acid battery supplier

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.