What is Electrical Contactor? Types of Magnetic

3 days ago · Magnetic Contactor Magnetic contactor is a device or switch which operates magnetically and close or open the electric circuit when needed.

Get Started

WEG CWB110 110A/150A 55kW/75kW

WEG Automation CWB Series Three Pole Contactor to 110A (AC3) or 150A (AC1) for a Power Circuit to be switched by a 110V TO 255V AC/DC (universal coil)

Get Started

Unlock the Power: Essential Answers About

Contactors are almost used in all control panels I see all the time in my work. Starting from small lighting control panels to medium voltage motor control

Get Started

What is An AC Contactor? Working and

Oct 10, 2023 · The main AC contactor function is to isolate high energy equipment or systems from their control circuits. That way, the switching

Get Started

The Different Types of Contactors and How They

Apr 21, 2021 · While technology has improved over years, the primary means of controlling electrical circuits remain the same. Among these are contactors,

Get Started

Deye inverter error: F31 AC Slave Contactor Fault

Mar 24, 2023 · Starting test of a Deye SUN-12K-SG04LP3-EU inverter, and looking for answers to a few issues: 1) AC is on, metering works, but when turning AC on (rotary breaker on side of

Get Started

DEYE INVERTER HELP DESK PH | Can anyone help what to do

Sep 4, 2024 · Can anyone help what to do with f30 error(ac main contactor fault) thanks Deye 12 kw hybrid inverter

Get Started

A Comprehensive Guide to AC Contactors

Mar 3, 2024 · AC contactors have a crucial role in electrical circuit systems. It helps in the effective control and management of electricity flow across

Get Started

AC Contactor: Working Principle & How It Works | Schneider

AC contactors play a crucial role in controlling power flow in electrical systems. Below is break down of their working principle into key components. 1. Coil Activation. The contactor features

Get Started

Grid Mains to Generator Changeover Relay Circuit

Dec 25, 2024 · The top/right grid mains contactor remains switched OFF due to the absence of a +12V DC. Therefore, the generator AC flows through this

Get Started

What is Contactor and their working, types and

Jun 28, 2024 · A contactor is a relay that is used for switching power.They usually handle very heavy loads like an electric motor, lighting and heating equipment

Get Started

Photovoltaic inverter main contactor failure

(Old AC main contactor failure inverter not have relays detec on func on) 4. restart Switching DC in PV Plants Contactors are typically selected for applications that need automatic remote

Get Started

WEG CWM250 250A/350A 132kW/175kW 3 Pole Contactor,

WEG Automation CWM Series Three Pole Contactor to 250A (AC3) or 350A (AC1) for a Power Circuit to be switched by a 110V to 130V AC Control Circuit. Rating:- - Motor DOL Starter

Get Started

Contactor needed for inverter output disconnect

Sep 12, 2011 · That still leaves the inputs of the inverters connected to the output of the generator. So the plan is to add a 50A contactor at the inverter inputs to keep it from trying to export

Get Started

Driving High-Voltage Contactors in EV and HEVs (Rev. A)

Jul 11, 2024 · The battery and the traction inverter are electrically isolated by main contactors when the vehicle is switched off for safety reasons. The main positive contactor is between the

Get Started

6. AC wiring

Aug 30, 2024 · Each inverter/charger contains an internal AC input contactor. These contactors are not always completely identical, they can have a small difference in their internal

Get Started

AC DC CONTACTOR Selection: Coil Voltage, Wiring, Cost Guide

Aug 14, 2025 · AC DC CONTACTOR selection guide comparing coil voltage types, wiring, and cost to help you choose the right contactor for your electrical system or automation setup.

Get Started

Sensata Precharge Circuit for Hybrid and Electric Vehicules

Dec 17, 2020 · However, most modern electric drive systems use inverters to control the motor directly, so the need for this type of contactor is somewhat limited. Closing a contactor into an

Get Started

Power contactors Series CU in central inverters

CU series power contactors have been specially developed for solar power systems. The double pole design ensures all-pole disconnection of the solar

Get Started

What is Contactor? Construction, Working,

4 days ago · Single Line Diagram The main disadvantage of the contactor is that they won''t protect the circuit from any other faults such as over current,

Get Started

Photovoltaic inverter main contactor failure

The central inverter is considered the most important core equipment in the Mega-scale PV power plant which suffers from several partial and total failures. This paper introduces a new

Get Started

AC Contactor in Solar Inverter, Battery Charging

Dec 15, 2016 · #4 "Re: AC Contactor in Solar Inverter, Battery Charging" by 67model on 12/15/2016 5:11 PM (score 1)

Get Started

Contactor before or after the VFD, or ? | Eng-Tips

Jun 17, 2004 · Re 1. A contactor in front of the VFD: Here''s some more AB PowerFlex manual text. "!ATTENTION: A contactor or other device that routinely disconnects and reapplies the

Get Started

Error Code

Feb 15, 2022 · Inverter went through its normal start up cycle - Wait 300 seconds, close DC contactor, IGBTs fire up, and then the DC contactor opens. The AC

Get Started

502012005【A】SUN-(12-15)K-G03-组串说明书-Ver2.0-D

Dec 29, 2020 · 1.1 Appearance Introduc on On-grid inverter can convert solar panel DC power into AC power which can directly input to the grid. Its appearance is shown below.These

Get Started

Frequency Inverter Safety: Contactors on input vs. output

Sep 5, 2018 · For example, should the contactors be on the input or the output? A contactor on the input of the frequency inverter rather than the output is preferred, although on can make

Get Started

A Comprehensive Guide to AC Contactors

Mar 3, 2024 · What is an AC Contactor? An AC contactor is an electromechanical switching device designed to switch AC loads on/off. It is used for switching

Get Started

Contactors

May 3, 2021 · Largest Issue I found with BMS contactor control is that if drive units are harmed with HV drop outs, best to have the drive unit control main contactors or not have them

Get Started

Main contactor and key connection. Zapi AC-3 FLASH INVERTER

User manual for Zapi AC-3 FLASH INVERTER . Describes features, installation, operation, diagnosis and more. Download the manual.

Get Started

6 FAQs about [Inverter AC main contactor]

What is AC contactor?

An AC contactor is an electromechanical switching device designed to switch AC loads on/off. It is used for switching high-current AC loads. The working principle of the AC contactor involves electromagnetic force cooperating with the spring force to make and break the connection between the source and load.

What components make an AC contactor?

The components that make an AC contactor are: Coil – The electromagnetic coil is the heart of the contactor. It creates a magnetic field that pulls the contacts together to close the circuit when energised. This coil is usually made of copper or aluminium wire. It is wound tightly to generate sufficient magnetic force.

How does a traction inverter work?

The battery and the traction inverter are electrically isolated by main contactors when the vehicle is switched off for safety reasons. The main positive contactor is between the positive battery pole and the traction inverter while the main negative contactor is between the negative battery pole and the traction inverter.

What are the different types of AC contactors?

AC contactors are mostly available in 3-pole and 4-pole versions. You can choose between them depending on the load type and control circuit requirements. For instance, 3-pole AC contactors are usable in three-phase systems, while 4-pole AC contactors can be used in 3 phase 4 wire system or 1 phase 2 wire system.

What is a single pole AC contactor?

The single pole AC contactor is one of the simplest ones available as it contains a single main contact. Such systems are commonly found in small air conditioning units in homes. It is simple in design as well as functionality. 2. Double Pole AC Contactor

What is an AC contactor switch?

Your AC contactor switch comes with terminals or connection points where you attach the wires that will go into it. These are usually labeled to make them identifiable based on their function. A typical contactor of this will have these terminals: A1 and A2: to connect the power supply, also called coil terminals.

Related Articles

-

AC contactor for inverter

AC contactor for inverter

-

12v AC to DC inverter price

12v AC to DC inverter price

-

How much does it cost to sell an AC inverter

How much does it cost to sell an AC inverter

-

Inverter can supply AC power

Inverter can supply AC power

-

12v inverter main components

12v inverter main components

-

Voltage inverter DC 110v to AC

Voltage inverter DC 110v to AC

-

AC V to V inverter

AC V to V inverter

-

AC slow charging connected to inverter

AC slow charging connected to inverter

-

AC power connected to DC inverter

AC power connected to DC inverter

-

High Power AC to DC Inverter Efficiency

High Power AC to DC Inverter Efficiency

Commercial & Industrial Solar Storage Market Growth

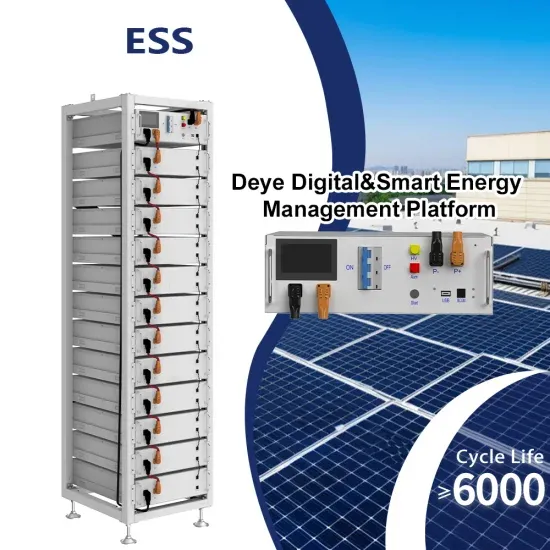

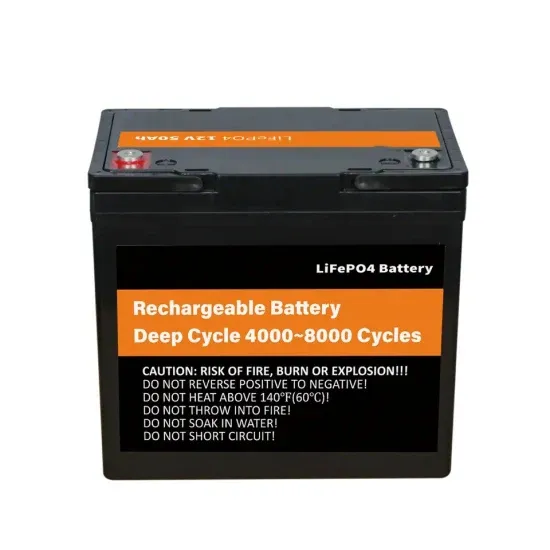

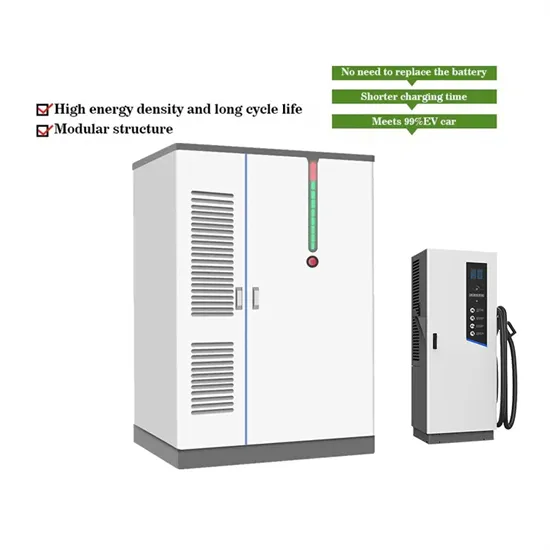

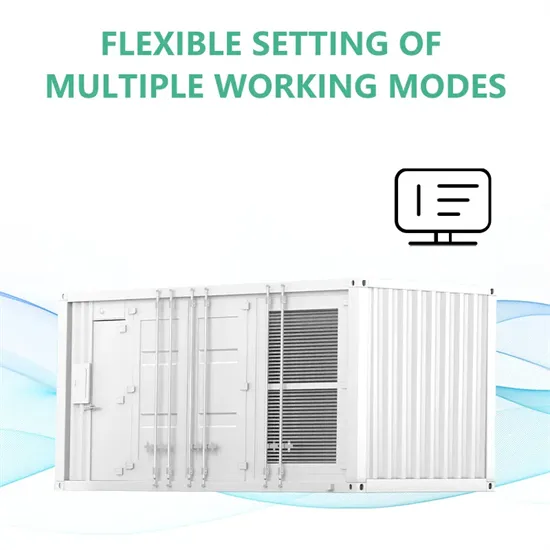

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.