Lead-acid batteries and lead–carbon hybrid systems: A review

Sep 30, 2023 · Therefore, lead-carbon hybrid batteries and supercapacitor systems have been developed to enhance energy-power density and cycle life. This review article provides an

Get Started

Carbon emission assessment of lithium iron phosphate batteries

Nov 1, 2024 · This study conducts a comparative assessment of the environmental impact of new and cascaded LFP batteries applied in communication base stations using a life cycle

Get Started

Techno-economic analysis of lithium-ion and lead-acid batteries

Aug 1, 2021 · The effectiveness of renewable energy sources as compared to the conventional sources was investigated by Dursun et al. [26] in which the techno-economic feasibility of a

Get Started

Comparison of lead-acid and lithium ion batteries for

Nov 15, 2016 · This paper compares these aspects between the lead-acid and lithium ion battery, the two primary options for stationary energy storage. The various properties and

Get Started

Dynamic charge acceptance of lead–acid batteries: Comparison

Jun 1, 2012 · Dynamic charge acceptance (DCA) is a key requirement for batteries in micro-hybrid vehicles. In automotive applications, DCA reaches a stable level during several weeks or

Get Started

Engineering Sciences

Jul 13, 2025 · in many new systems. Hybrid systems, where supercapacitors respond to sudden load demands and sealed lead-acid batteries meet long-term energy needs, are considered

Get Started

A comprehensive overview of electric vehicle batteries market

Mar 1, 2023 · Lead-Acid, Nickel Metal Hydride, and Lithium-ion batteries are the commonly used types of batteries for Electric-Drive Vehicles (EDVs), including Battery Electric Vehicles

Get Started

Comparison study of lead-acid and lithium-ıon batteries for

The power supply quality and reliability are improved by utilizing battery energy storage technologies in conjunction with solar photovoltaic systems. This paper presents a

Get Started

Comparison of power backup schemes for

Compared with traditional lead-acid batteries, ladder products have obvious advantages in environmental pollution, cycle life and fast charge and

Get Started

LEAD-ACID BATTERIES ARE NOT GOING AWAY

Jul 26, 2019 · The important common factor in all of the applications described above is that these are always maintained and operated at 100% state-of-charge (SOC). That being the case, let

Get Started

Assessment of high power HEV lead-acid battery

Jul 1, 2003 · The technical and practical suitability of lead-acid batteries for applications in vehicles with electrical drivetrains (battery-powered or hybrid ele

Get Started

IEEE-CED Battery Technology Comparison

Mar 11, 2020 · The future of batteries – Lithium-ion 1976: Exxon researcher – Whittingham described lithium-ion concept in Science publication entitled "Electrical Energy Storage and

Get Started

Lead–acid batteries for future automobiles: Status and prospects

Jan 1, 2017 · Research projects in the framework of the Advanced Lead–Acid Battery Consortium (ALABC) have demonstrated the application of advanced AGM batteries in various medium

Get Started

Comparison of off-grid power supply systems using lead-acid

Mar 1, 2018 · Request PDF | Comparison of off-grid power supply systems using lead-acid and lithium-ion batteries | Solar home systems (SHS) and solar photovoltaic village power supply

Get Started

A comparison of lead-acid and lithium-based battery

Aug 29, 2016 · Studies of capacity fade in off-grid fi renewable systems focus almost exclusively on lead-acid batte-ries, although lithium-based battery technologies, including LCO (lithium

Get Started

Design and control of the hybrid lithium-ion/lead–acid battery

Oct 1, 2023 · This paper describes method of design and control of a hybrid battery built with lead–acid and lithium-ion batteries. In the proposed hybrid, bidirectional interleaved DC/DC

Get Started

Comparison of different lead–acid battery lifetime prediction models

Feb 15, 2014 · Abstract Lifetime estimation of lead–acid batteries in stand-alone photovoltaic (PV) systems is a complex task because it depends on the operating conditions of the batteries. In

Get Started

A Review on the Recent Advances in Battery

The automotive sector, global hybrid transportation systems, grid stability, electric vehicles, and rail-system power models are examples of current industry

Get Started

Environmental feasibility of secondary use of electric vehicle

May 1, 2020 · Repurposing spent batteries in communication base stations (CBSs) is a promising option to dispose massive spent lithium-ion batteries (LIBs) from electric vehicles (EVs), yet

Get Started

Hybrid Electrical Energy Supply System with Different

Jun 21, 2025 · Two different types of batteries are considered for storage purposes; lead-acid and vanadium redox-flow batteries (VRB) batteries. Most stand-alone energy systems for various

Get Started

Hybrid lead-acid/lithium-ion energy storage system with power

Sep 9, 2016 · The performance versus cost tradeoffs of a fully electric, hybrid energy storage system (HESS), using lithium-ion (LI) and lead-acid (PbA) batteries, are explored in this work

Get Started

Lead-Acid Batteries in Telecommunications: Powering...

Critical Infrastructure: Telecommunications infrastructure, including cell towers, base stations, and communication hubs, requires a constant and reliable power supply. Lead-acid batteries serve

Get Started

Lead–acid batteries for hybrid electric vehicles and battery electric

Jan 1, 2015 · As a consequence, several car makers have already introduced or are developing dual storage solutions that combine the robust lead–acid base starter battery with a high

Get Started

A comprehensive review of battery technology for E-mobility

Oct 1, 2021 · In this review, various battery technologies used in electric vehicles are discussed in detail with their research advancements. In the market, various types of electric vehicles along

Get Started

Comparison of off-grid power supply systems using lead-acid

Mar 1, 2018 · Solar home systems (SHS) and solar photovoltaic village power supply systems can play an important role in the supply of electrical energy to off-grid areas. This paper presents a

Get Started

1561-2019

Jun 7, 2019 · Abstract: This guide is applicable to lead-acid batteries that are used as the energy storage component in remote hybrid power supplies. The remote hybrid application, with its

Get Started

(PDF) Multiphysics Engineered Next-Generation

Feb 24, 2025 · This report explores advancements in lead-acid battery technology, focusing on innovations that enhance their application in electric

Get Started

High-power lead–acid batteries for different applications

Jun 15, 2005 · High-power lead–acid batteries have been used for a rather long time in various applications, especially for uninterruptible power supplies (UPSs) and starting of automobiles.

Get Started

Drone endurance in hydrogen fuel cell hybrid technologies: Power

In order to compare the various drone power sources, along with FCs, three different battery types—Li-ion, Ni-Cd, and Ni-Mh—are contrasted and examined in Refs. [231, 232], taking into

Get Started

6 FAQs about [Comparison of hybrid power sources of lead-acid batteries for communication base stations in various industries]

What is the difference between lithium battery and lead-acid technology?

Also, in power grid applications the lead–acid technology allows the provision of power up to 10 MW compared to lithium technology which is limited to 1 MW , . However, lithium battery technology is used in stationary applications and more largely in embedded systems such as hybrid vehicle .

Which lead-acid battery is used?

The six lead-acid cells used here are VRLA (valve-regulated lead-acid) batteries rated 6 V 4.5 Ah. VRLA cells are selected instead of flooded cells due to their recommended usage in applications with partial cycling at low states of charge [13,35].

Which battery technology is used in a hybrid vehicle?

However, lithium battery technology is used in stationary applications and more largely in embedded systems such as hybrid vehicle . This is due to its high performance and low weight. In addition, to improve the performance of hybrid electrification systems both battery technologies are used simultaneously .

Can lead-acid batteries and super-capacitors be used as energy buffers?

It is valuable to study the combined system of lead-acid batteries and super-capacitors in the context of photovoltaic and wind power systems [8–10]. Battery is one of the most cost-effective energy storage technologies. However, using battery as energy buffer is problematic .

Can a hybrid energy storage system improve battery life?

This will also have a negative impact on the battery life, increase the project cost and lead to pollute the environment. This study proposes a method to improve battery life: the hybrid energy storage system of super-capacitor and lead-acid battery is the key to solve these problems.

Can lead-acid labs be used in a lithium-ion battery system?

An application of lead–acid in mild hybrids (12 V or even 48 V) would be possible if the dynamic charge acceptance and the total cycling throughput could be improved. The use of advanced LABs in dual systems with lithium-ion batteries would also be possible.

Related Articles

-

Technical Specifications for Photovoltaic Power Generation with Lead-acid Batteries for Communication Base Stations

Technical Specifications for Photovoltaic Power Generation with Lead-acid Batteries for Communication Base Stations

-

Ranking of solar hybrid power sources for communication base stations in Ecuador

Ranking of solar hybrid power sources for communication base stations in Ecuador

-

Connection between lead-acid batteries in communication base stations

Connection between lead-acid batteries in communication base stations

-

What are the hybrid energy sources for the new communication base stations in Manama

What are the hybrid energy sources for the new communication base stations in Manama

-

Does Tonga have lead-acid batteries for communication base stations in China

Does Tonga have lead-acid batteries for communication base stations in China

-

Tender for maintenance and repair of wind-solar hybrid power generation for communication base stations in Vanuatu

Tender for maintenance and repair of wind-solar hybrid power generation for communication base stations in Vanuatu

-

Does East Asia have lead-acid batteries for communication base stations in China

Does East Asia have lead-acid batteries for communication base stations in China

-

Wind-solar hybrid photovoltaic power generation for communication base stations to save energy and reduce consumption

Wind-solar hybrid photovoltaic power generation for communication base stations to save energy and reduce consumption

-

Tender for lead-acid batteries for Maputo communication base stations

Tender for lead-acid batteries for Maputo communication base stations

-

Design of wind-solar hybrid power generation system for communication base stations in Northern Cyprus

Design of wind-solar hybrid power generation system for communication base stations in Northern Cyprus

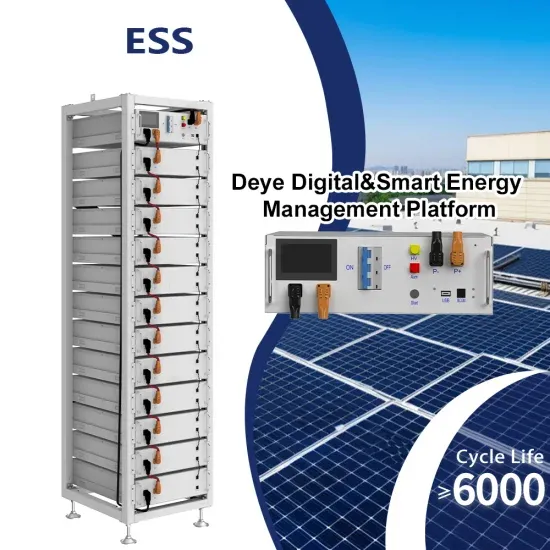

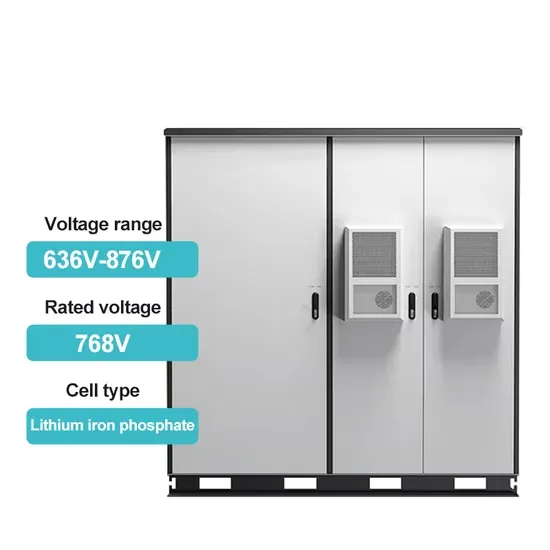

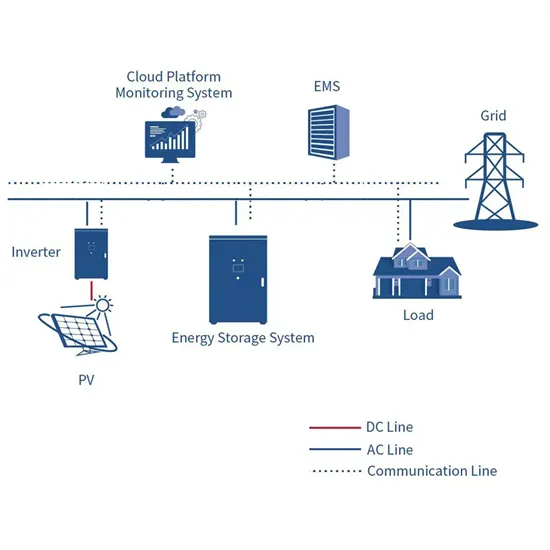

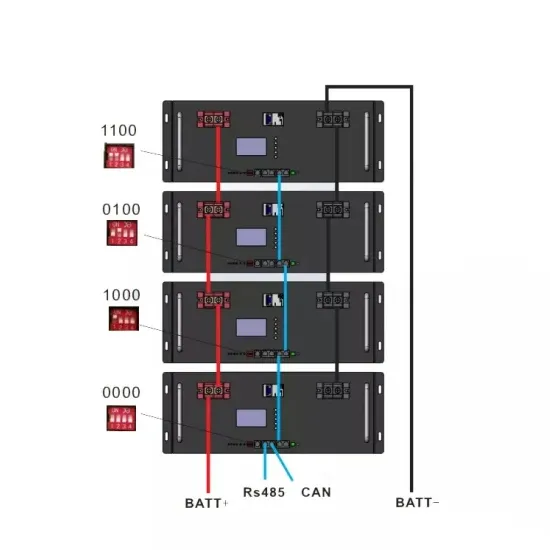

Commercial & Industrial Solar Storage Market Growth

The global commercial and industrial solar energy storage battery market is experiencing unprecedented growth, with demand increasing by over 400% in the past three years. Large-scale battery storage solutions now account for approximately 45% of all new commercial solar installations worldwide. North America leads with 42% market share, driven by corporate sustainability goals and federal investment tax credits that reduce total system costs by 30-35%. Europe follows with 35% market share, where standardized industrial storage designs have cut installation timelines by 60% compared to custom solutions. Asia-Pacific represents the fastest-growing region at 50% CAGR, with manufacturing innovations reducing system prices by 20% annually. Emerging markets are adopting commercial storage for peak shaving and energy cost reduction, with typical payback periods of 3-6 years. Modern industrial installations now feature integrated systems with 50kWh to multi-megawatt capacity at costs below $500/kWh for complete energy solutions.

Solar Battery Innovations & Industrial Cost Benefits

Technological advancements are dramatically improving solar energy storage battery performance while reducing costs for commercial applications. Next-generation battery management systems maintain optimal performance with 50% less energy loss, extending battery lifespan to 20+ years. Standardized plug-and-play designs have reduced installation costs from $1,000/kW to $550/kW since 2022. Smart integration features now allow industrial systems to operate as virtual power plants, increasing business savings by 40% through time-of-use optimization and grid services. Safety innovations including multi-stage protection and thermal management systems have reduced insurance premiums by 30% for commercial storage installations. New modular designs enable capacity expansion through simple battery additions at just $450/kWh for incremental storage. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show standard industrial systems (50-100kWh) starting at $25,000 and premium systems (200-500kWh) from $100,000, with flexible financing options available for businesses.